Novel environment-friendly touch decorative plate and manufacturing method thereof

A decorative board and environmental protection technology, applied in the field of decorative materials, can solve the problems of easily damaged surface treatment layer, difficult control of material color consistency, high process cost, and achieve environmental protection of preparation process and products, easy to use and popularize, and widely used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

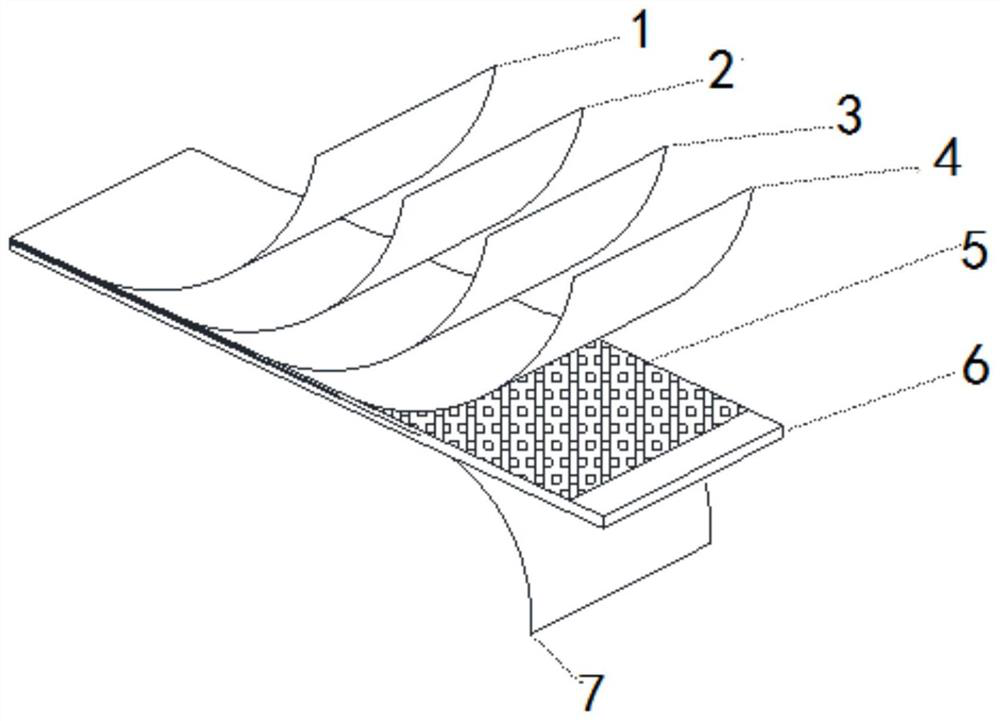

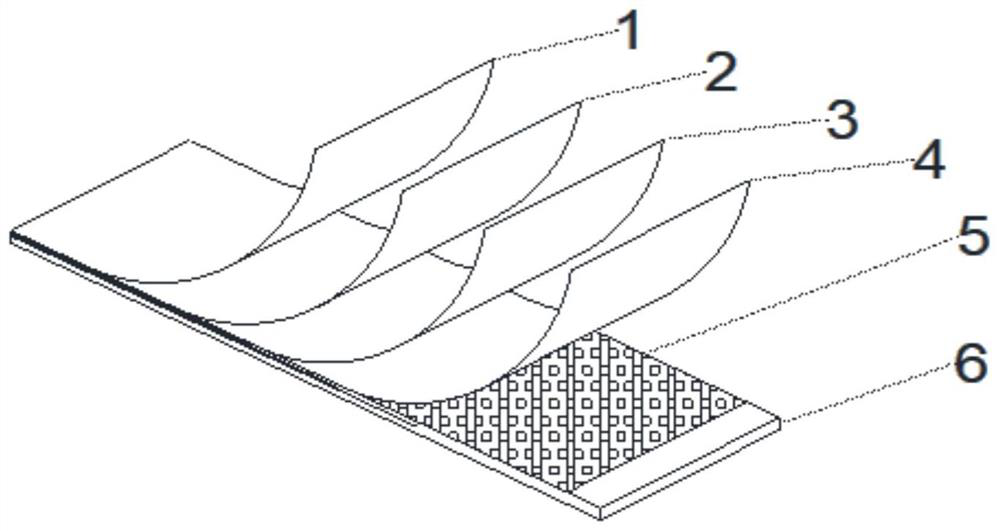

[0032] see figure 1 , in the embodiment of the present invention, a new type of environmentally friendly tactile decorative board, including a base material layer 6, on which a tactile effect layer 5 that highlights its 3D concave-convex shape is provided, and the tactile effect layer 5 deviates from the base One side of the material layer 6 is provided with a surface structure layer 2 that protects the concave-convex shape on the tactile effect layer 5, and the inner side of the surface structure layer 2 toward the tactile effect layer 5 is provided with a surface structure layer for upwardly facing the concave-convex shape on the tactile effect layer 5. The colored surface color layer 3, the surface structure layer 2 and the surface color layer 3 are closely attached to the base material layer 6 through the intermediate adhesive layer 4, and are formed in the middle of the same side of the base material layer 6 from inside to outside. The multi-layer bonding mechanism of the...

Embodiment 2

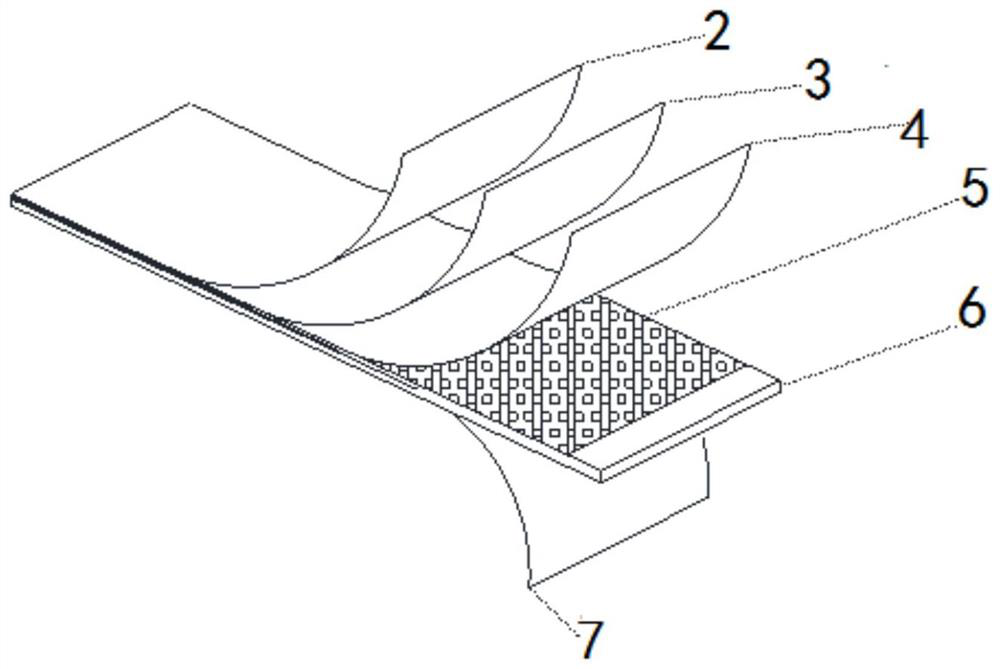

[0039] Such as figure 1 and figure 2 As shown, on the basis of this embodiment and embodiment 1, the surface protection performance of the new environmentally friendly tactile decorative board is further improved, specifically:

[0040] The surface structure layer 2 is also provided with a surface protection layer 1 relative to the outside of the base material layer 6, and the surface protection layer 1 can be a polyester protection film such as PE protective film (ie polyethylene protective film), kraft paper, PET, etc. etc. can protect the surface effect layer. According to the specific use requirements, a surface protection layer 1 is selected to be added to the surface structure layer 2, and the surface protection layer 1 is used to provide the outermost flexible protection for the board.

Embodiment 3

[0042] Such as figure 1 and image 3 As shown, on the basis of this embodiment and embodiment 1, the anti-rust performance of the installation of the new environmentally friendly tactile decorative board is further improved, specifically:

[0043] The other side of the base material layer 6 relative to the surface structure layer 2 is also provided with a back protection layer 7, and the back protection layer 7 can be coated with one or more layers on the surface of the base material layer 6 by a roll coating process. Epoxy or polyester coating to achieve decorative or anti-corrosion properties;

[0044] The back protective layer 7 can also be pasted on the surface of the base material layer 6 by casting a hot-melt adhesive layer on the surface of the polyester film to form a decorative expansion, anti-corrosion and heat insulation performance to improve the product; additional Protect the back of the product by bonding a layer of polyester protective film such as PE protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com