Comprehensive beneficiation and quality improvement method under a condition that bauxite is difficult to utilize

A bauxite, upgrading technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, magnetic separation, etc., can solve the problem of low added value, difficult to use bauxite comprehensive beneficiation and upgrading methods, ore utilization efficiency Low and other problems, to achieve the effect of short time, low ore utilization efficiency and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

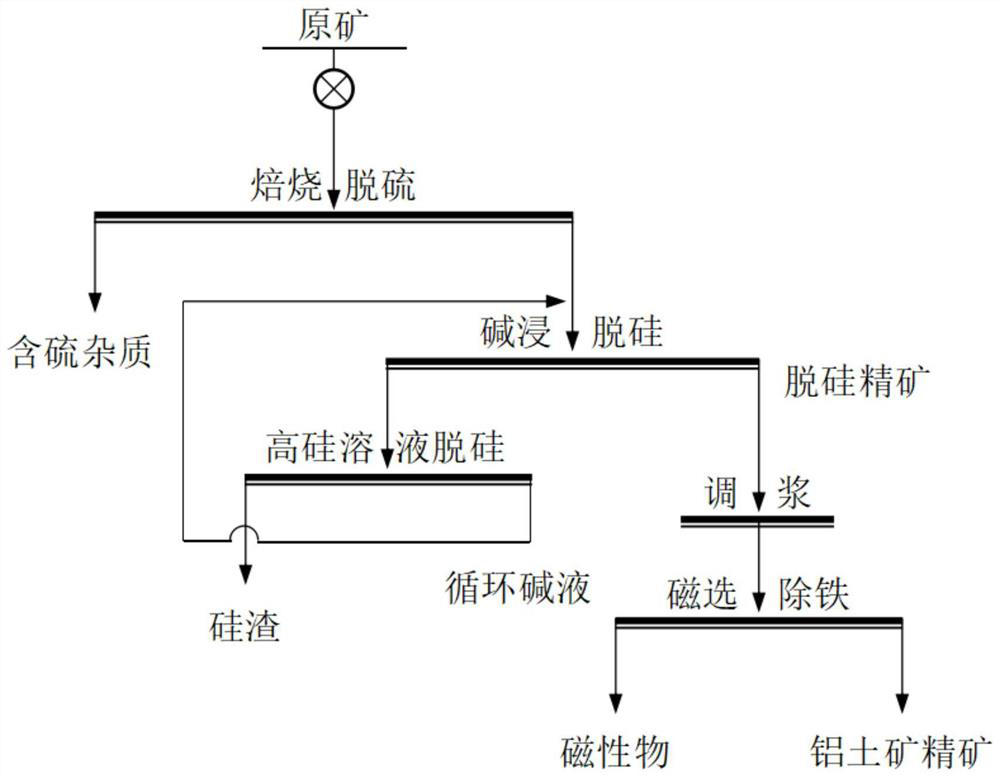

[0019] Such as figure 1 Shown, a kind of refractory bauxite comprehensive beneficiation and upgrading method of the present invention comprises the following steps:

[0020] (1) After the raw ore is crushed and ground to a particle size of 150 mesh ore content ≥ 70%, it is fed into the preheater through the feeder, and the ore powder is preheated to 200°C, and then enters the suspension roasting furnace at 600 Roasting at ℃, and keep for 5s to complete desulfurization, the high-temperature ore powder after roasting and desulfurization is cooled to below 100℃ by cyclone cooler to obtain desulfurization concentrate;

[0021] (2) Add the desulfurized concentrate obtained in step (1) into a leaching tank filled with caustic soda with an alkali concentration of 80g / L, adjust the liquid-solid ratio to 6:1, and leaching at a temperature of 90°C for 10 minutes to obtain leach slurry;

[0022] (3) performing solid-liquid separation on the leaching slurry obtained in step (2) to obtai...

Embodiment 2

[0026] Such as figure 1 Shown, a kind of refractory bauxite comprehensive beneficiation upgrading method comprises the following steps:

[0027] (1) After crushing and grinding the raw ore until the particle size is 180 mesh, the content of fine ore is ≥ 70%, and then feed it into the preheater through the feeder, preheat the ore powder to 250 ° C, and then enter the suspension roasting furnace at 800 Roasting at ℃, and keep for 8s to complete desulfurization, the high-temperature ore powder after roasting and desulfurization is cooled to below 100℃ by cyclone cooler to obtain desulfurization concentrate;

[0028] (2) Add the desulfurized concentrate obtained in step (1) into a leaching tank filled with caustic soda with an alkali concentration of 120g / L, and adjust the liquid-solid ratio to 8:1, and leaching at a temperature of 92°C for 20 minutes to obtain leach slurry;

[0029] (3) performing solid-liquid separation on the leaching slurry obtained in step (2) to obtain a ...

Embodiment 3

[0033] Such as figure 1 Shown, a kind of refractory bauxite comprehensive beneficiation upgrading method comprises the following steps:

[0034] (1) After the raw ore is crushed and ground to a particle size of 200 mesh ore content ≥ 70%, it is fed into the preheater through the feeder, and the ore powder is preheated to 300°C, and then enters the suspension roasting furnace at 950 Roasting at ℃, and keep for 10s to complete desulfurization, the high-temperature ore powder after roasting and desulfurization is cooled to below 100℃ by cyclone cooler to obtain desulfurization concentrate;

[0035] (2) Add the desulfurized concentrate obtained in step (1) into a leaching tank filled with caustic soda with an alkali concentration of 150g / L, and adjust the liquid-solid ratio to 10:1, and leaching at a temperature of 95°C for 30 minutes to obtain leach slurry;

[0036] (3) performing solid-liquid separation on the leaching slurry obtained in step (2) to obtain a desiliconized conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com