Rolling bearing fault diagnosis method based on SA-ACWGAN-GP

A rolling bearing and fault diagnosis technology, applied in the field of fault diagnosis, can solve problems such as inability to understand the spatial distribution and internal structure of samples, inability to realize data distribution characteristics, poor diagnosis effect, etc. Reduced effect of parameter calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

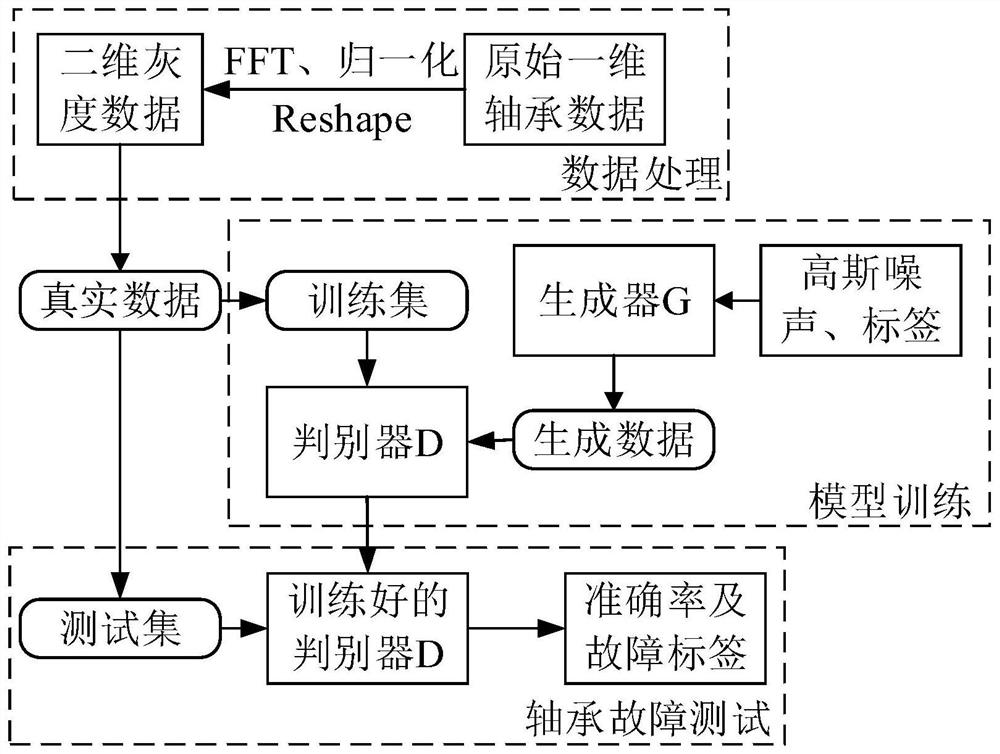

[0058] This application provides a rolling bearing fault diagnosis method based on SA-ACWGAN-GP (Self Attention Mechanism-Auxiliary Classifier Wasserstein GAN-Gradient Penalty), the process is as follows figure 1 As shown, the specific implementation process of the method includes the following steps:

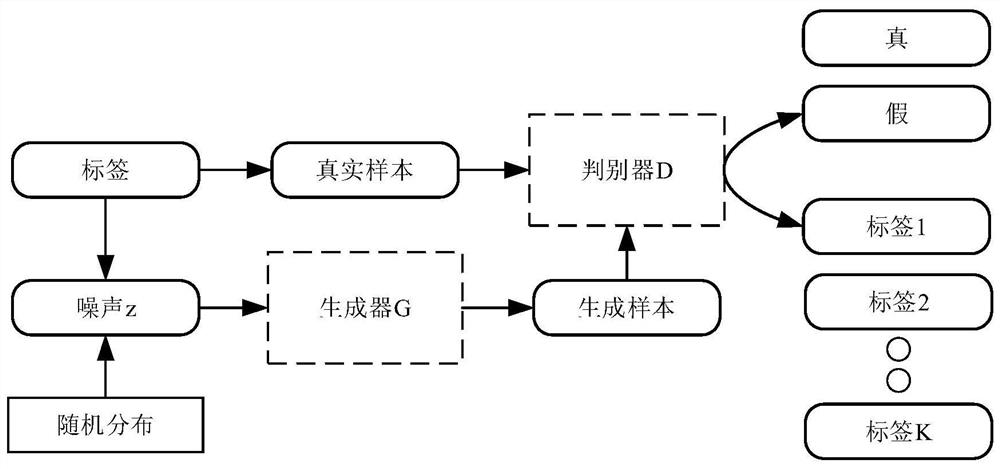

[0059] to combine figure 2 As shown, the auxiliary classification generative adversarial network is mainly composed of a generator G and a discriminator D. The discriminator D intends to distinguish whether the data source is real data, and needs to judge the type of data. fake samples. After the model training is completed, the vibration signal of the rolling bearing in an unknown state is input into the discriminator D to output the bearing fault category.

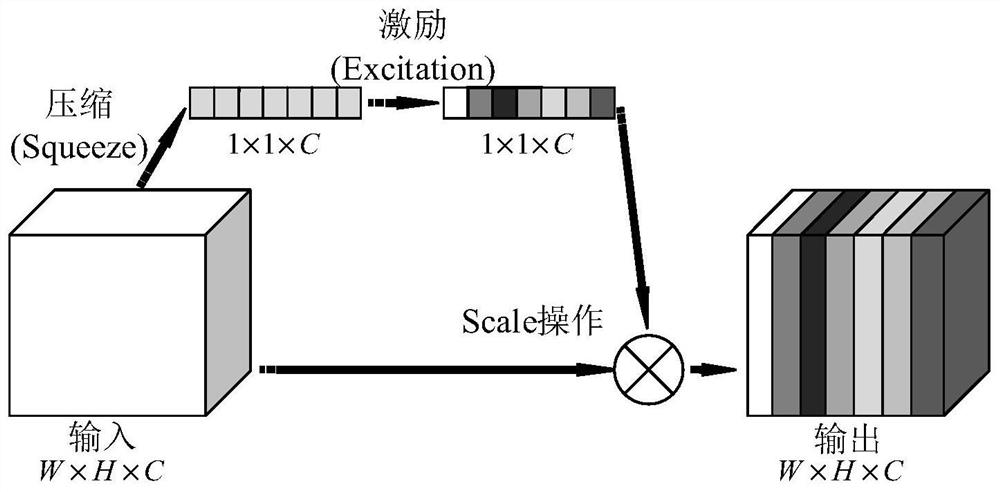

[0060] Such as image 3 As shown, this application introduces a parameter ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com