Method for improving adhesive force of electrophoretic deposition energetic film, improved energetic film and application

An electrophoretic deposition and adhesion technology, used in electrophoretic plating, electrolytic coatings, offensive equipment, etc., can solve the problems of complex improvement methods and difficult process control of electrodeposited films, and achieve increased physical stability and weather resistance, and improved adhesion. Focusing on the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

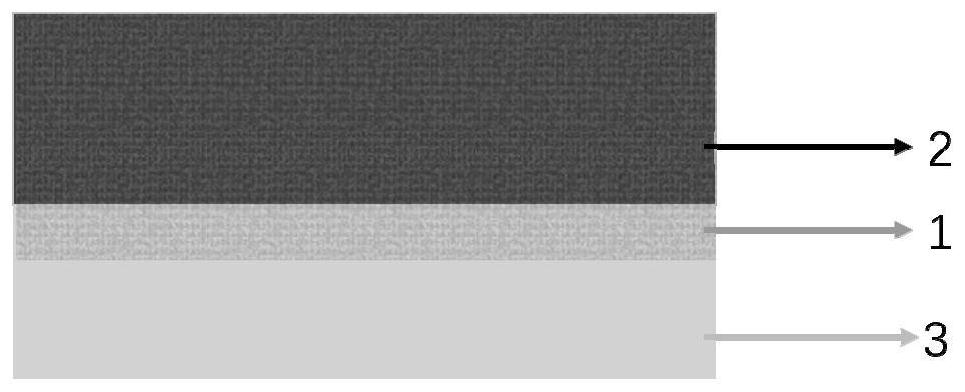

Image

Examples

Embodiment 1

[0046] A method of improving electrophoretic deposition Al / CuO containing film adhesion, including the following steps:

[0047] (1) The nano-aluminum powder and the copper oxide powder were added to a mass ratio of 1: 2, and 40 Hz was normal temperature ultrasound for 10 to 15 minutes, and the uniform suspension A was prepared.

[0048] (2) Grinding the pure copper sheets to the surface of 5000 mesh sandpaper to the surface bright and flat, and use acetone, ethanol, deionized water, and blow drying drying;

[0049](3) 0.1 ml of thirteenofluoromethoxysilane, add 100 ml of anhydrous ethanol and deionized water mixing solution, ultrasonic 10min, and thirteen fluoroctyltriethoxysilane solution A;

[0050] (4) Set the electrophoretic device to 150V, deposition time is set for 5 min, as an intensive and inferior electrode, suspension A is used as an electrolyte, and a uniform Al / CuO containing film is obtained in a vacuum 60 ° C. Dry 30 h;

[0051] (5) The dry load has a copper pie...

Embodiment 2

[0055] A method of improving electrophoretic deposition Al / CuO containing film adhesion, including the following steps:

[0056] (1) The nano-aluminum powder and copper oxide powder were added to a mass ratio of 1: 2, and 40 Hz was normal temperature ultrasound 10 to 15 min, and the uniform suspension B was prepared.

[0057] (2) Grinding the pure copper sheets to the surface of 5000 mesh sandpaper to the surface bright and flat, and use acetone, ethanol, deionized water, and blow drying drying;

[0058] (3) 0.5 ml of thirteen fluoroctyltriethoxysilane, add 100 ml of anhydrous ethanol and deionized water mixing solution, ultrasonic 10min, and a thirteen fluoroctyltriethoxysilane solution C;

[0059] (4) Set the electrophoretic device to 150V, deposition time is set for 5 min, as an intensive and inferior electrode, suspension A is used as an electrolyte, and a uniform Al / CuO containing film is obtained in a vacuum 60 ° C. Dry 3h;

[0060] (5) Immerse the dry load of the Al / C...

Embodiment 3

[0064] A method of improving electrophoretic deposition Al / CuO containing film adhesion, including the following steps:

[0065] (1) The nano-aluminum powder and copper oxide powder were added to a mass ratio of 1: 2, and 40 Hz was normal temperature ultrasound 10 to 15 min, and the uniform suspension B was prepared.

[0066] (2) Grinding the pure copper sheets to the surface of 5000 mesh sandpaper to the surface bright and flat, and use acetone, ethanol, deionized water, and blow drying drying;

[0067] (3) 0.5 ml of thirteenfluoromethoxysilane, added to 100 ml of anhydrous ethanol and deionized water mixing solution, ultrasonic 10min, and thirteen fluoroctyltriethoxysilane solution D;

[0068] (4) Set the electrophoretic device to 150V, deposition time is provided for 5 min, as an intensive and inferior electrode, the suspension A is used as an electrolyte, and a uniform Al / CuO film is obtained on the surface of the cathode copper sheet, and in a vacuum 60 ° C Dry 3h;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com