Silver-based brazing process of nuclear magnetic equipment

A silver-based brazing and equipment technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as physical injury, high current density, and welding difficulties, and achieve low production cost, low steam pressure, and good wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

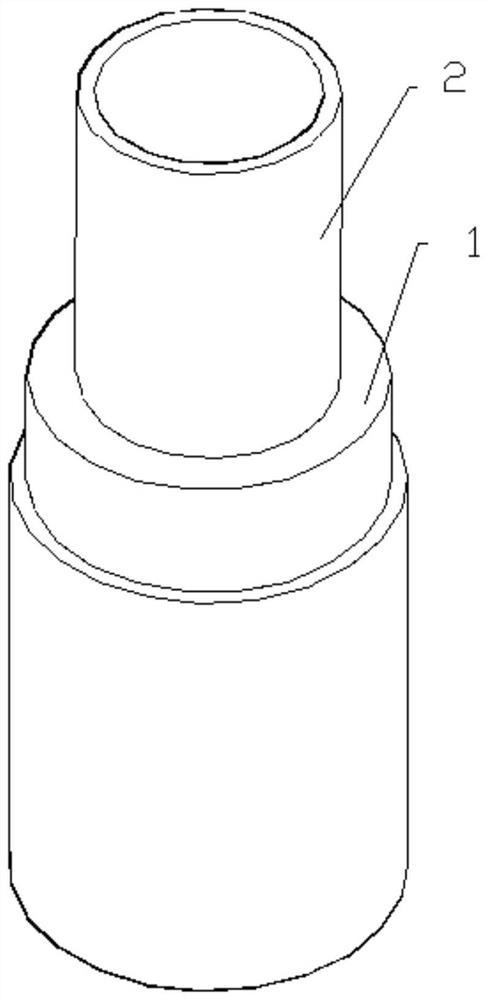

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0022] A silver-based brazing process for nuclear magnetic equipment, comprising the following steps: step 1, selecting AgCuIn27-10 as a brazing material, and using SiC sandpaper to polish the surface of the brazing material until it is above grade 1000; step 2, using SiC sandpaper to The base metal is polished until it is more than 1000 grades, and the base metal is a copper tube and a stainless steel tube; Step 3, using acetone to ultrasonically clean the surface of the brazing material and the base metal for 3-5 minutes to remove surface impurities; Step 4, make brazing flux, use a metal container to hold QJ102 solder powder, brew it into a paste with boiling water, heat it with low heat to dissolve and mix it into brazing flux, and apply the brazing flux to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com