Antimonate chemical conversion treatment solution for improving corrosion resistance of magnesium alloy

An antimonate chemical and conversion treatment technology, which is applied in the coating process of metal materials, etc., can solve the problems of general self-healing performance, fast solution consumption, instability, etc., and achieves expanded application range, uniform and flat conversion film, and simple composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

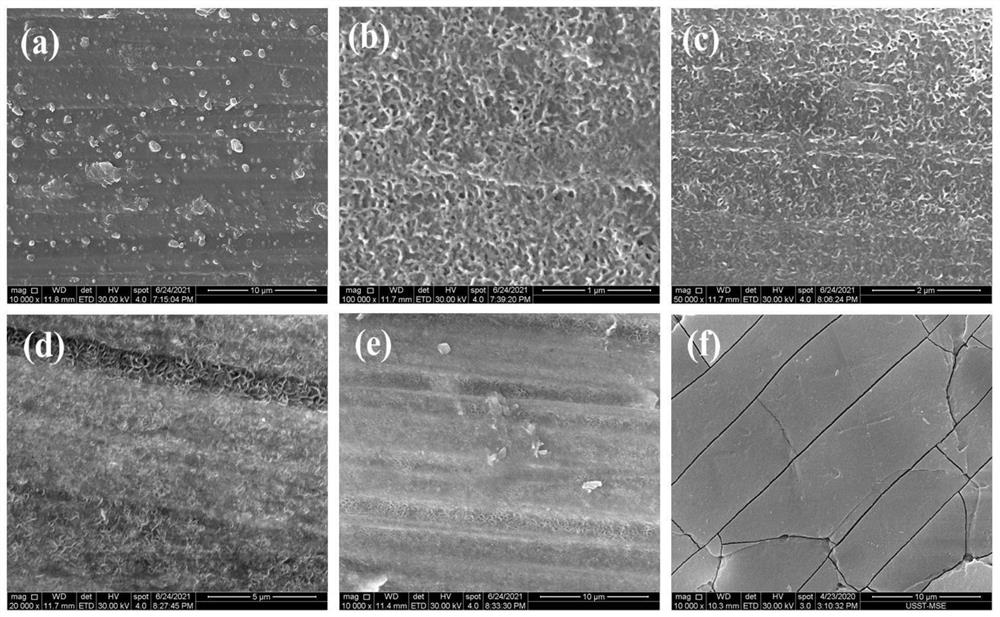

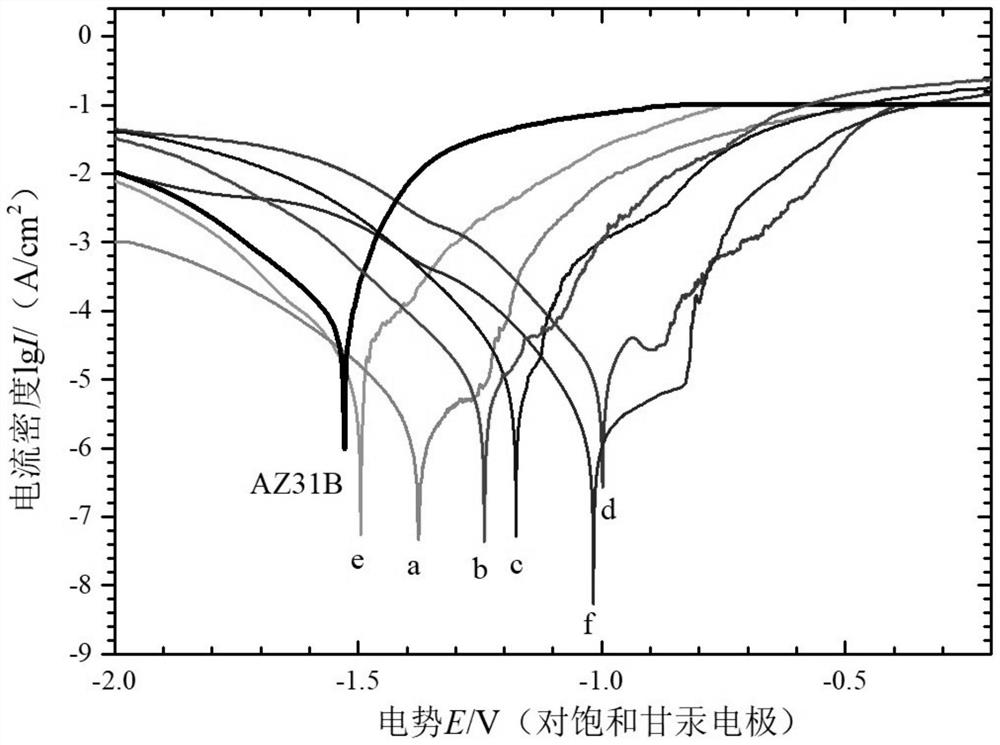

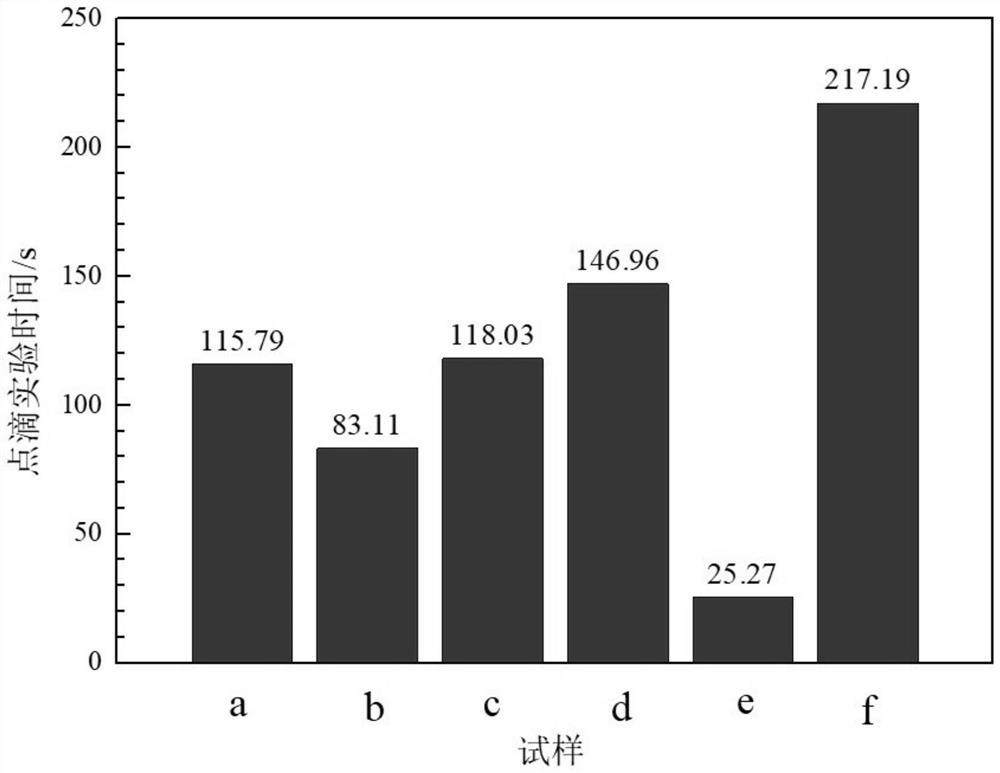

Image

Examples

Embodiment 1

[0077] A kind of antimonate chemical conversion treatment solution for improving the corrosion resistance of magnesium alloy, including solvent and solute, solvent is water, solute includes antimonate and co-solvent, antimonate is potassium hexahydroxy antimonate, co-solvent It is triethanolamine, the concentration of potassium hexahydroxyantimonate is 0.3mol / L, and the concentration of triethanolamine is 0.5mol / L.

[0078] A method for using the above-mentioned antimonate chemical conversion treatment solution in preparing a magnesium alloy chemical conversion film, specifically comprising the following steps:

[0079] 1. Pretreatment: Cut out a sample with a size of 40mm×10mm×1mm from the AZ31B magnesium alloy plate. Use 200#, 400#, 800#, 1500# silicon carbide water abrasive paper successively to polish the surface evenly.

[0080] 2. The solution used and operating conditions: the aqueous solution is prepared with deionized water, and the composition and content are as fol...

Embodiment 2

[0091] A kind of antimonate chemical conversion treatment solution for improving the corrosion resistance of magnesium alloy, including solvent and solute, solvent is water, solute includes antimonate and co-solvent, antimonate is potassium hexahydroxy antimonate, co-solvent It is glycerol, the concentration of potassium hexahydroxyantimonate is 0.25mol / L, and the concentration of glycerol is 0.5mol / L.

[0092] A method for using the above-mentioned antimonate chemical conversion treatment solution in preparing a magnesium alloy chemical conversion film, specifically comprising the following steps:

[0093] 1. Pretreatment: Cut out a sample with a size of 40mm×10mm×1mm from the AZ31B magnesium alloy plate. Use 200#, 400#, 800#, 1500# silicon carbide water abrasive paper successively to polish the surface evenly.

[0094] 2. The solution used and operating conditions: the aqueous solution is prepared with deionized water, and the composition and content are as follows.

[009...

Embodiment 3

[0105] A kind of antimonate chemical conversion treatment solution for improving the corrosion resistance of magnesium alloy, including solvent and solute, solvent is water, solute includes antimonate and co-solvent, antimonate is potassium hexahydroxy antimonate, co-solvent It is sorbitol, the concentration of potassium hexahydroxyantimonate is 0.5mol / L, and the concentration of sorbitol is 1mol / L.

[0106] A method for using the above-mentioned antimonate chemical conversion treatment solution in preparing a magnesium alloy chemical conversion film, specifically comprising the following steps:

[0107] 1. Pretreatment of the sample: cut out a sample with a size of 40mm×10mm×1mm from the AZ31B magnesium alloy plate. Use 200#, 400#, 800#, 1500# silicon carbide water abrasive paper successively to polish the surface evenly.

[0108] 2. The solution used and operating conditions: the aqueous solution is prepared with deionized water, and the composition and content are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com