High-strength heat-resistant magnesium alloy sheet and manufacturing method thereof

A magnesium alloy, heat-resistant technology, used in metal rolling, heat treatment equipment, profile control, etc., can solve problems such as difficult leveling, poor low-temperature plasticity, and reduced sheet performance, to improve production efficiency, eliminate deformation stress, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

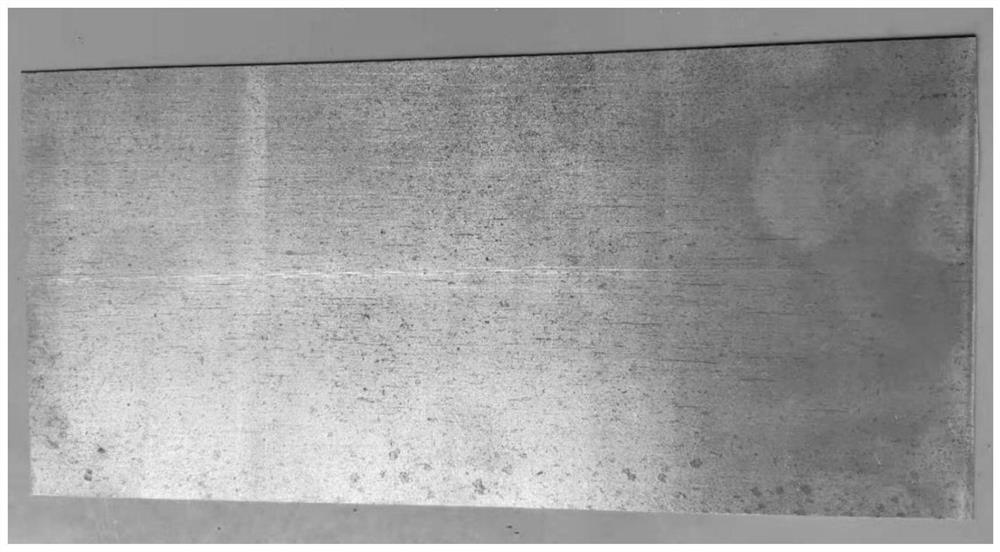

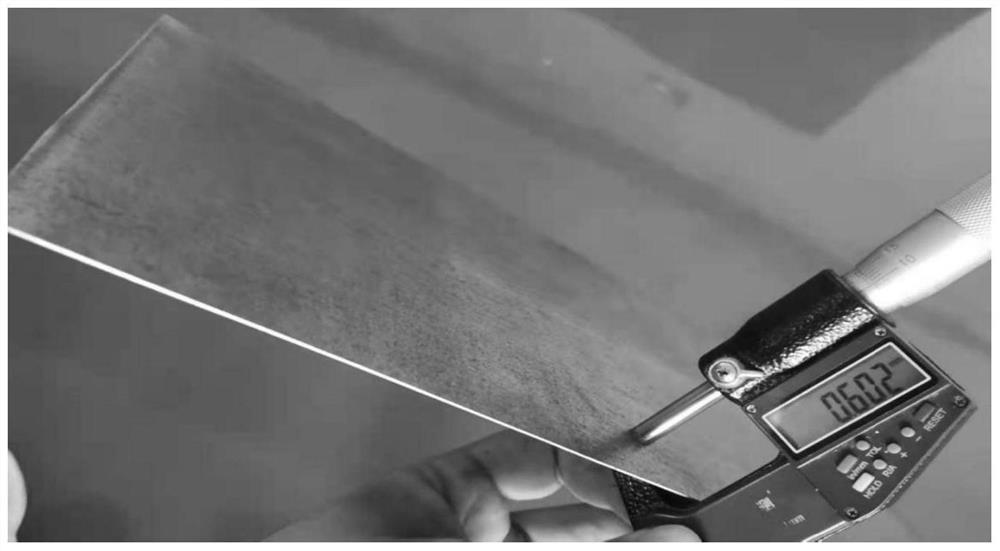

[0036] Preparation of Mg-9.2Gd-2.6Y-0.5Zr(VW93) Alloy Sheet

[0037] a) A VW93 magnesium alloy billet of 10*200*250mm was kept at 520°C for 2 hours for preheating.

[0038] b) The preheated billet is hot-rolled to a thickness of about 5mm through 3 fires, and the reductions of each heat are 10%, 22.2% and 28.6% respectively; The rolling direction and the vertical direction are continuously reversed and rolled, the rolling speed is 10m / min, the roll temperature is 180°C, and the fire insulation is kept at 520°C for 20min. The 5mm-thick plate was kept at 520°C for 1.5h for the first intermediate annealing. After the first annealing is completed, it is hot rolled to a thickness of about 1.5mm after 4 fires, and the reductions are 20%, 30%, 28.6% and 25% respectively; the rolling speed is 14m / min, the roll temperature is 200°C, and the fire is kept Incubate at 520°C for 15 minutes. The 1.5mm thick plate was kept at 520°C for 1h for the second intermediate annealing. After the ...

Embodiment 2

[0044] Preparation of Mg-9.2Gd-2.6Y-0.5Zr(VW93) Alloy Sheet

[0045] a) A VW93 magnesium alloy billet of 10*200*250mm was kept at 520°C for 2 hours for preheating.

[0046]b) The preheated billet is hot rolled to a thickness of about 5 mm through 3 fires, and the reduction amount of each fire (that is, the deformation amount of each fire) is 10%, 22.2% and 28.6% respectively; 4 passes per fire Rolling, during the rolling process, the rolling direction and the vertical direction are continuously reversed and rolled, the rolling speed is 10m / min, the roll temperature is 180°C, and the fire insulation is kept at 520°C for 20min. The 5mm-thick plate was kept at 520°C for 1.5h for the first intermediate annealing. After the first annealing is completed, it is hot rolled to a thickness of about 1.5mm after 4 fires, and the reductions are 20%, 30%, 28.6% and 25% respectively; the rolling speed is 14m / min, the roll temperature is 200°C, and the fire is kept Incubate at 520°C for 15 ...

Embodiment 3

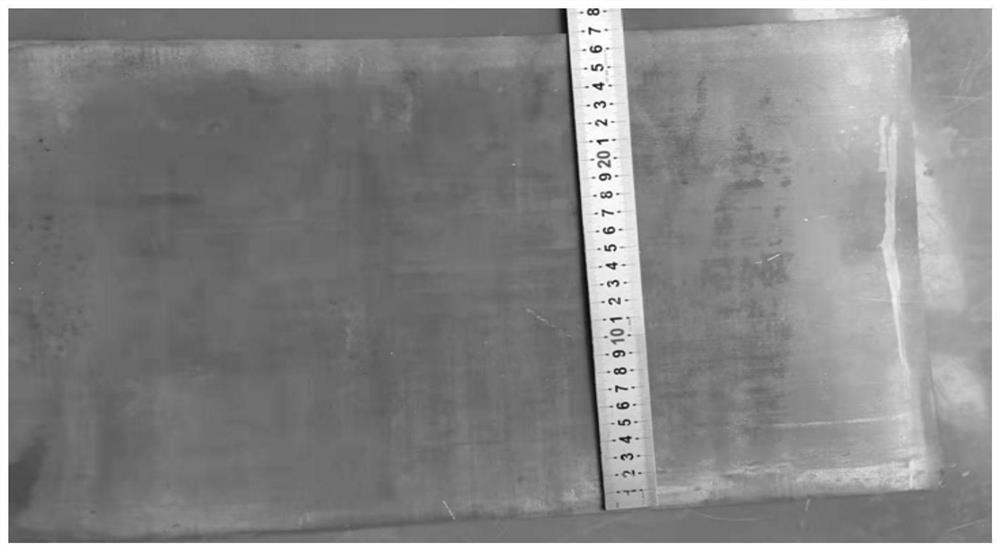

[0052] Preparation of Mg-9.2Gd-2.6Y-0.5Zr(VW93) Alloy Sheet

[0053] a) A VW93 magnesium alloy billet of 8*300*280mm is kept at 480° C. for 3 hours for preheating.

[0054] b) The preheated billet is hot-rolled to a thickness of about 3mm after 3 fires, and the reductions per fire (that is, the deformation per fire) are respectively 25%, 33.3% and 25%; each fire is rolled 4 times , during the rolling process, the rolling direction and the vertical direction are continuously reversed and rolled, the rolling speed is 12m / min, the roll temperature is 220°C, and the fire insulation is kept at 480°C for 25min. The 3mm-thick plate was kept at 480°C for 2h for the first intermediate annealing. After the first annealing time is up, it is hot-rolled to a thickness of about 1mm after 3 fires, and the reductions are 30%, 28.6% and 33.3% respectively; the rolling speed is 14m / min, the temperature of the roll is 200°C, and the fire insulation is at 480°C Keep warm for 20min. The 1.5mm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com