Plasma medical refuse burning methods

A technology of medical waste and plasma, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of short life of plasma burners, high requirements for heat exchangers, unfavorable large-scale centralized treatment, etc., and achieve the goal of controlling toxic gases Low production, manufacturing and anti-corrosion requirements, which are conducive to the effect of large-scale centralized treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

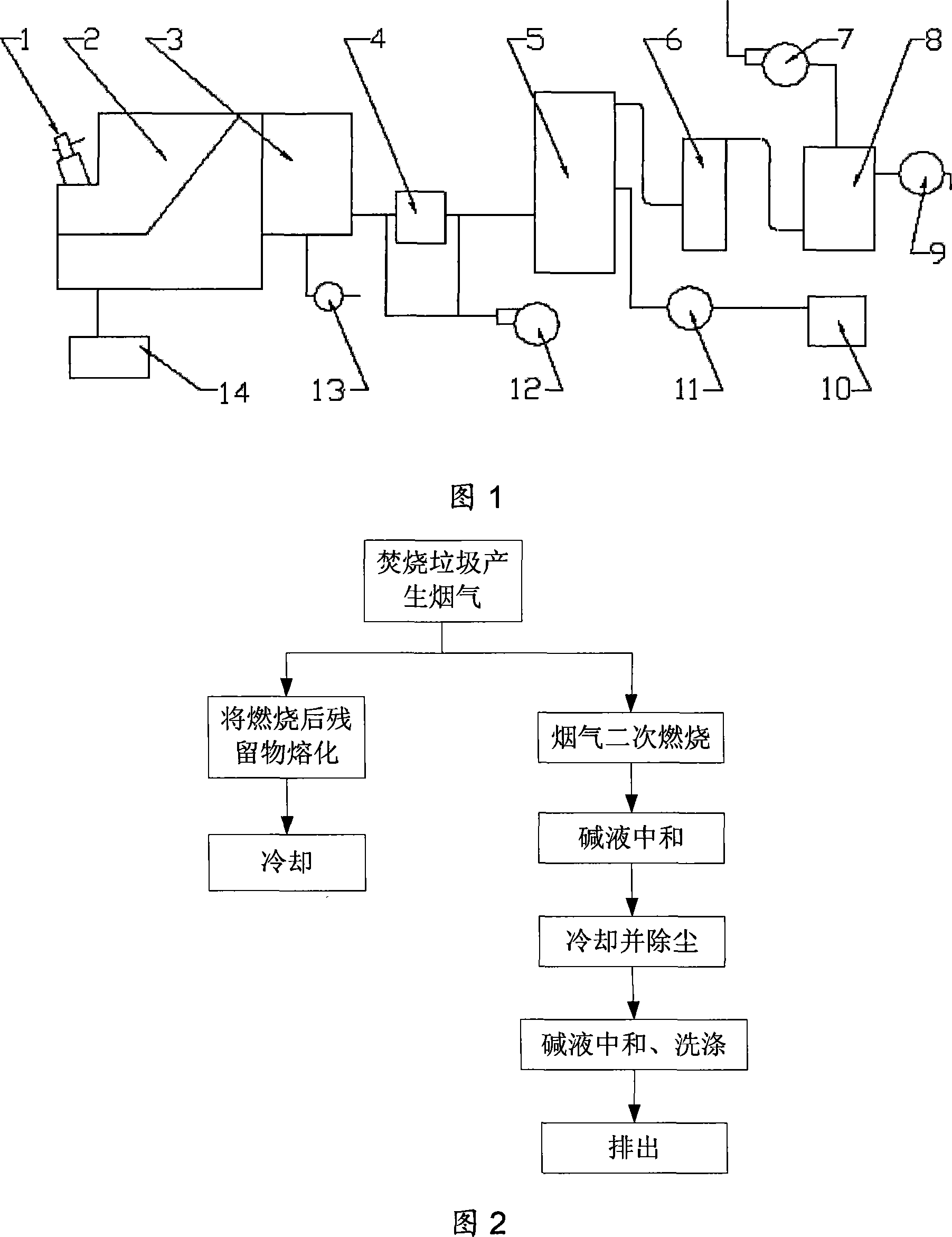

[0026] As shown in Figure 1, it is the device schematic diagram that the inventive method implements, and Fig. 2 is the flow chart of the inventive method, below in conjunction with Fig. 1, Fig. 2 specifically introduces the inventive method realization process, specifically as follows:

[0027] The device that the inventive method implements comprises plasma torch 1, incinerator 2, secondary combustion chamber 3, heat exchanger 4, cooling tower 5, deduster 6, induced draft fan 7, purifier 8, slurry pump 9, pool 10, cleaning Water pump 11, air blower 12, lye pump 13 and slag remover 14.

[0028] (1) Use the plasma gun 1 to raise the temperature in the incinerator 2 to above 1100°C, burn the medical waste in the incinerator 2, and control the oxygen content in the incinerator 2 to be less than 0.09%, so that the incinerator 2 is at a high reduction non-toxic state; the residue after combustion is melted in the melting chamber at the lower part of the incinerator 2, and the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com