Polyurethane foaming rubber, preparation method and application thereof, and soft package lithium ion battery

A technology of polyurethane foam and foaming agent, which is applied in polyurea/polyurethane adhesives, secondary batteries, battery pack components, etc., and can solve problems affecting the electrical performance and safety performance of batteries, and prone to deformation. , to achieve excellent mechanical properties and mechanical properties, reduce deformation, and ensure the effect of mechanical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 500g of polyadipate-1,4-butylene glycol ester diol, 200g of diphenylmethane diisocyanate, 100g of 1,4-butanediol, and 10g of triethylenediamine, and heat the above raw materials to 100°C, and vacuum dehydration for 2h; add the dehydrated diphenylmethane diisocyanate dropwise to the dehydrated poly(1,4-butylene adipate)diol, stir for 0.5h, rotate at 1000r / min, and then drop Add the dehydrated cross-linking agent and catalyst, stir for 1h, rotate at 1000r / min, and raise the temperature to 80°C at the same time to obtain component 1;

[0037] Mix 30g of vinyltriethoxysilane, 20g of fluorodichloroethane, 30g of graphene and 60g of water and dichloromethane at room temperature, heat to 85°C, and vacuum dehydrate for 1h; after the reaction, cool to 30 °C to obtain component two.

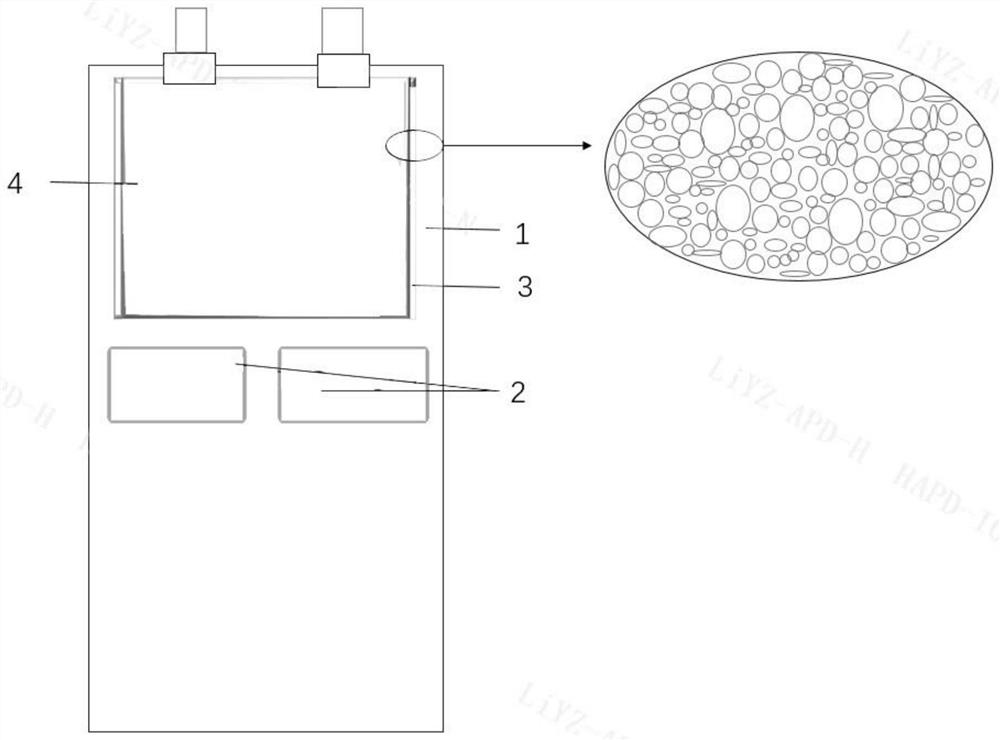

[0038] Mix components 1 and 2 with a styrofoam glue gun and fill them into the left and right gaps between the cell and the inner pit of the aluminum-plastic film 1, cure at room temperature ...

Embodiment 2

[0040] Weigh 500g polyadipate-1,4-butylene glycol ester diol, 250g dodecylbenzene-2,4-diisocyanate, 100g 1,4-butanediol, 10g triethylenediamine, and mix the above raw materials Heat to 100°C respectively, and vacuum dehydrate for 2h; add the dehydrated diphenylmethane diisocyanate dropwise to the dehydrated poly(1,4-butylene adipate)diol, stir for 0.5h, and rotate at 1000r / min, then drop the dehydrated crosslinking agent and catalyst respectively, stir for 1h, rotate at 1000r / min, and raise the temperature to 80°C at the same time to obtain component one;

[0041]Mix 30g of vinyltriethoxysilane, 30g of fluorodichloroethane, 25g of silicon dioxide and 60g of water and dichloromethane at room temperature, heat to 85°C, and vacuum dehydrate for 1h; after the reaction, cool to Component 2 was obtained at 30°C.

[0042] Mix components 1 and 2 with a styrofoam glue gun and fill them into the left and right gaps between the cell and the inner pit of the aluminum-plastic film 1, cur...

Embodiment 3

[0044] Weigh 500g polyadipate-1,4-butylene glycol ester diol, 250g dodecylbenzene-2,4-diisocyanate, 100g 1,4-butanediol, 10g triethylenediamine according to the rights Heat to 100°C and vacuum dehydrate for 2h; add the dehydrated diphenylmethane diisocyanate dropwise to the dehydrated poly(1,4-butylene adipate)diol, stir for 0.5h, and rotate at 1000r / min, then drop the dehydrated cross-linking agent and catalyst respectively, stir for 1 h at a speed of 1000 r / min, and raise the temperature to 80°C at the same time to obtain component 1;

[0045] Mix 30g of vinyltriethoxysilane, 20g of fluorodichloroethane, 25g of calcium oxide and 50g of water and dichloromethane at room temperature, heat to 85°C, and vacuum dehydrate for 1h; after the reaction, cool to 30 °C to obtain component two.

[0046] Mix components 1 and 2 with a styrofoam glue gun and fill them into the left and right gaps between the cell and the inner pit of the aluminum-plastic film 1, cure at room temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com