Continuous production method for recovering phenylacetic acid from 7-amino-3-vinyl cephalosporanic acid production wastewater

A technology based on cephalosporanic acid and wastewater production, applied in the field of medicine, can solve the problems of low adsorption efficiency of macroporous resins, long desorption process time, cumbersome treatment process, etc. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

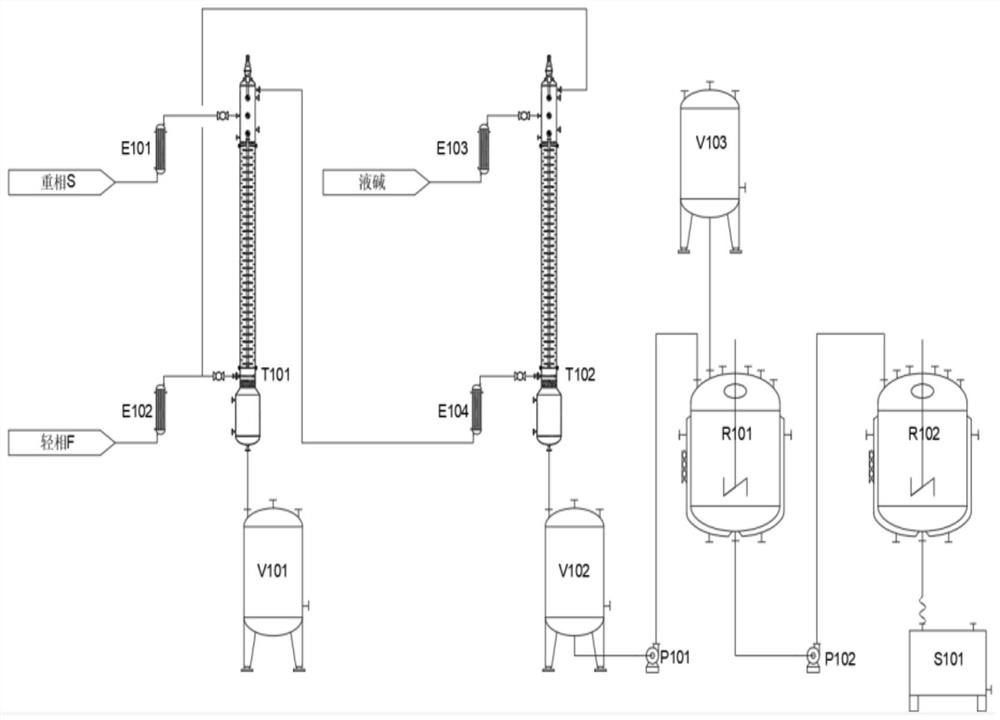

Image

Examples

Embodiment 1

[0048] In this example, the number of stages of the extraction tower T101 is 7, the number of revolutions is 80r / min, the waste water is acidified to a pH value of 2, the content of phenylacetic acid is 1%, the temperature of the extraction tower is 35°C, the extraction agent is butyl acetate, and the extraction agent The mass ratio to waste water is 0.05:1, the temperature of the extractant entering the tower is 35°C, and the extraction residue is extracted from the bottom of the tower. After analysis by high-efficiency gas chromatography, the content of phenylacetic acid in the extraction residue is 0.04%, and the extraction efficiency is 96.0%. The number of stages of the extraction tower T102 is 7, the number of revolutions is 80r / min, the content of the organic solvent phenylacetic acid is 19.20%, and the temperature of the extraction tower T102 is 35° C. The ratio is 6:1, the liquid caustic soda enters the tower at a temperature of 35°C, and the remaining extraction phase...

Embodiment 2

[0052] In this example, the number of stages of the extraction tower T101 is 7, the number of revolutions is 60r / min, the waste water is acidified to a pH value of 4, the content of phenylacetic acid is 0.8%, the temperature of the extraction tower is 35°C, the extraction agent is butyl acetate, and the extraction agent The mass ratio to waste water is 0.1:1, the temperature of the extractant entering the tower is 30°C, and the extraction residue is extracted from the bottom of the tower. After analysis by high-efficiency gas chromatography, the content of phenylacetic acid in the extraction residue is 0.06%, and the extraction efficiency is 92.5%. The number of stages of the extraction tower T102 is 7, the number of revolutions is 80r / min, the content of organic solvent phenylacetic acid is 7.4%, the temperature of entering the extraction tower T102 is 35°C, the organic solvent containing phenylacetic acid and liquid caustic soda (liquid caustic soda is 5% sodium bicarbonate aq...

Embodiment 3

[0055] In this example, the number of stages of the extraction tower T101 is 7, the number of revolutions is 80r / min, the waste water is acidified to a pH value of 2, the content of phenylacetic acid is 1%, the temperature of the extraction tower is 35°C, the extraction agent is butyl acetate, and the extraction agent The mass ratio to waste water is 0.05:1, the temperature of the extractant entering the tower is 35°C, and the extraction residue is extracted from the bottom of the tower. After analysis by high-efficiency gas chromatography, the content of phenylacetic acid in the extraction residue is 0.04%, and the extraction efficiency is 96.0%. The number of stages of the extraction tower T102 is 7, the number of revolutions is 60r / min, the organic solvent phenylacetic acid content is 19.2%, enters the extraction tower T102 temperature 35 ℃, contains the organic solvent of phenylacetic acid and the mass of liquid caustic soda (liquid caustic soda is 10% sodium carbonate aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com