122 type iron-based superconductor and preparation method thereof

An iron-based superconductor and iron powder technology, applied in the field of superconductors, can solve the problems of uniformity, contradicting high efficiency, uneven distribution, and harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

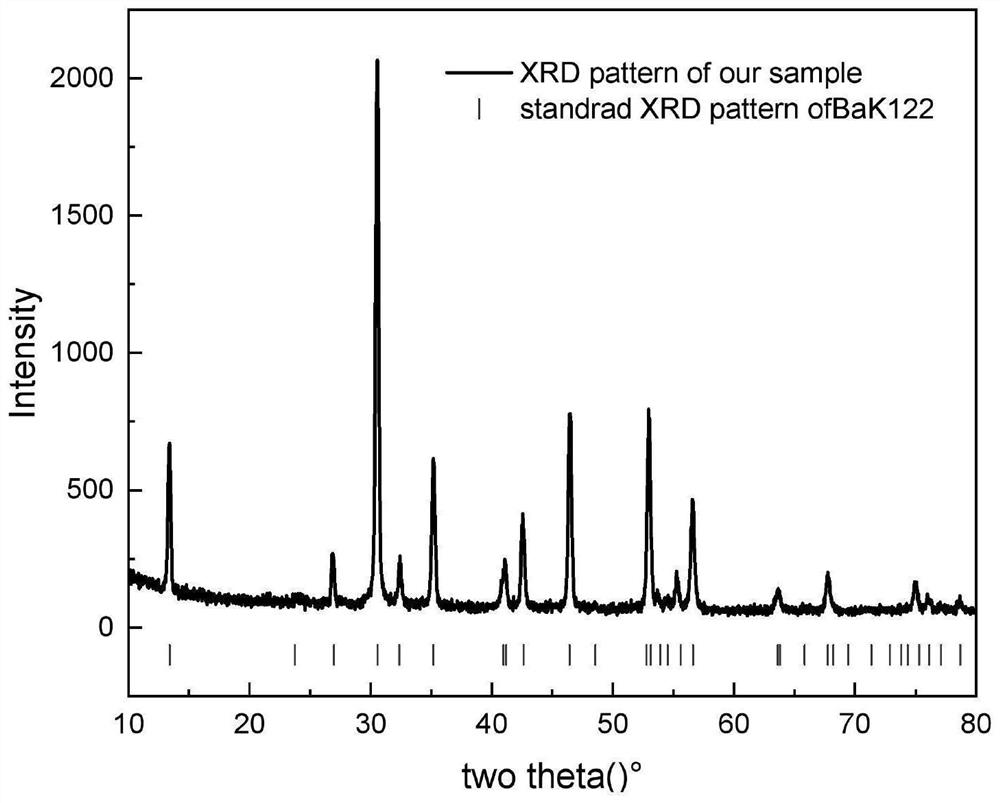

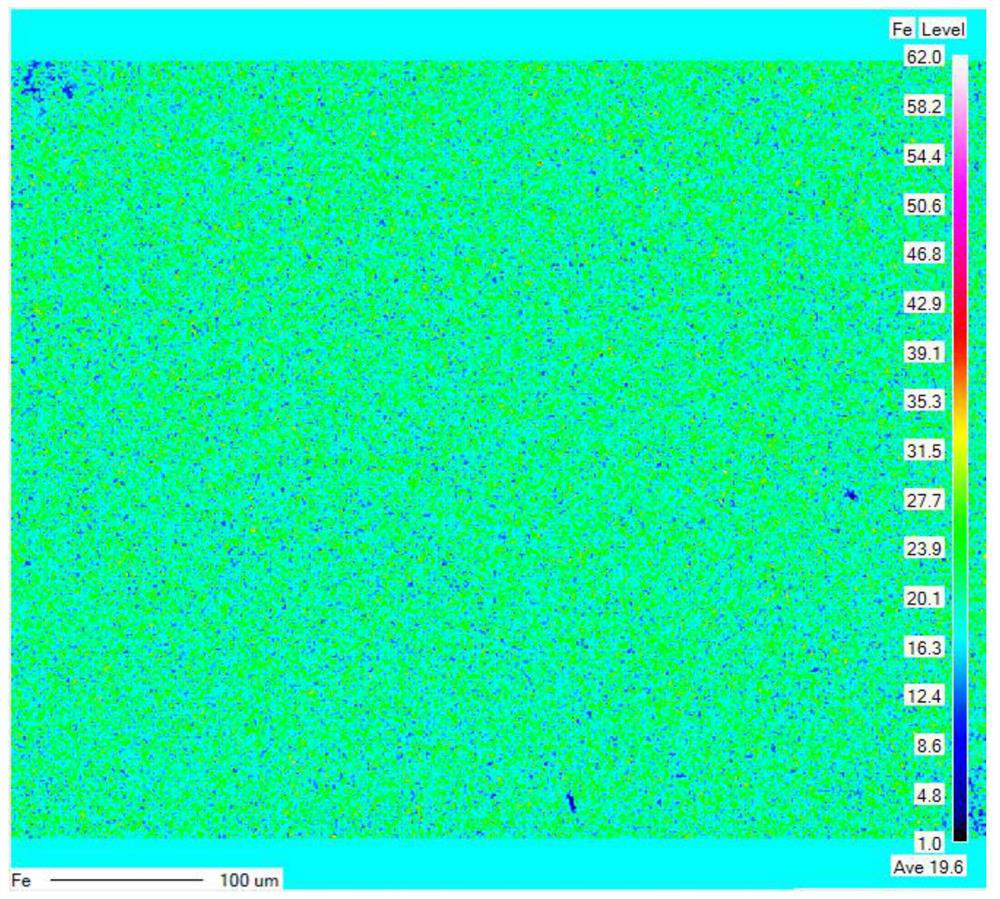

[0027] The invention provides a preparation method of a 122-type iron-based superconductor, wherein the chemical formula of the 122-type iron-based superconductor is Ba 0.6 K 0.4 Fe 2 As 2 , including the following steps:

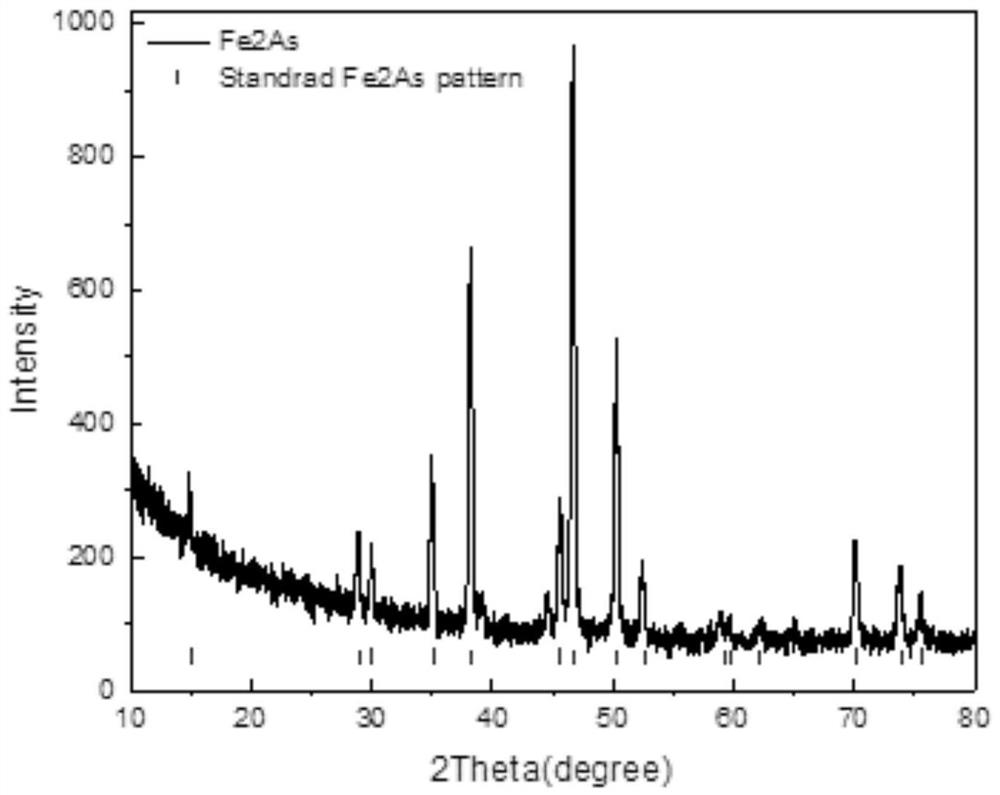

[0028] The iron element and the first arsenic element are mixed, and the first ball milling and the first sintering are performed in sequence to obtain Fe 2 As embryo;

[0029] the Fe 2 As embryo body, barium element, potassium element and second arsenic element are mixed, and the second ball milling, pressing and second sintering are performed in sequence to obtain the Ba 0.6 K 0.4 Fe 2 As 2 .

[0030] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0031] In the present invention, the iron element and the arsenic element are mixed, and the first ball milling and the first sintering are performed in sequence to obtain Fe 2 As embryo body.

[...

Embodiment 1

[0048] 1. Under the protection of an inert atmosphere, Fe powder (purity 99.5%, particle size ~10μm) and crushed As powder (purity 99.5%, particle size ~100μm) are uniformly mixed at a molar ratio of 2:1.08, sealed into Mill in a 250mL ball mill tank at a speed of 500r / min for 2 hours, a total of three times, and the tank needs to be opened under the protection of an inert atmosphere in the middle to prevent uneven ball milling.

[0049] 2. After ball milling, place the Fe+As mixture in an Al 2 o 3 In the crucible, the outside is covered with a stainless steel tube for protection, and the two ends of the stainless steel tube are welded in an argon atmosphere.

[0050] 3. Put the sealed stainless steel tube into the muffle furnace for sintering, raise the temperature to 700°C at a rate of 6K / min for 24 hours, and then cool in the furnace to obtain Fe with uniform phase formation, less impurities and higher density. 2 As embryo body.

[0051] 4. The prepared Fe 2 As embryo b...

Embodiment 2

[0077] 1. Under the protection of inert atmosphere, Fe powder (purity of 99.5%, particle size of ~10μm) and crushed As powder (purity of 99.5%, particle size of ~100μm) were uniformly mixed in a molar ratio of 2:1.08, and sealed into a In a 250mL ball milling jar, the ball was milled at a speed of 400r / min for 2 hours, a total of 3 times, and the jar should be opened under the protection of an inert atmosphere in the middle to prevent uneven ball milling.

[0078] 2. After the ball milling is completed, Fe 2 The As mixture is placed in an Al 2 O 3 In the crucible, the outside is covered with a stainless steel tube for protection, and both ends of the stainless steel tube are welded and sealed in an argon atmosphere.

[0079] 3. Put the sealed stainless steel tube into a muffle furnace for sintering, heat it up to 720 °C at a rate of 6K / min and keep it for 12 hours, and then cool it in the furnace to obtain Fe with uniform phase, less impurities and higher density. 2 As embr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com