Preservative film with intelligent microorganism self-inhibition effect and preparation method of preservative film

An inhibitory, microbial technology, used in biochemical fiber processing, filament/thread forming, single-component polyester rayon, etc. Good capacitance and enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a preservative film with microbial intelligence self-inhibition, the specific steps are:

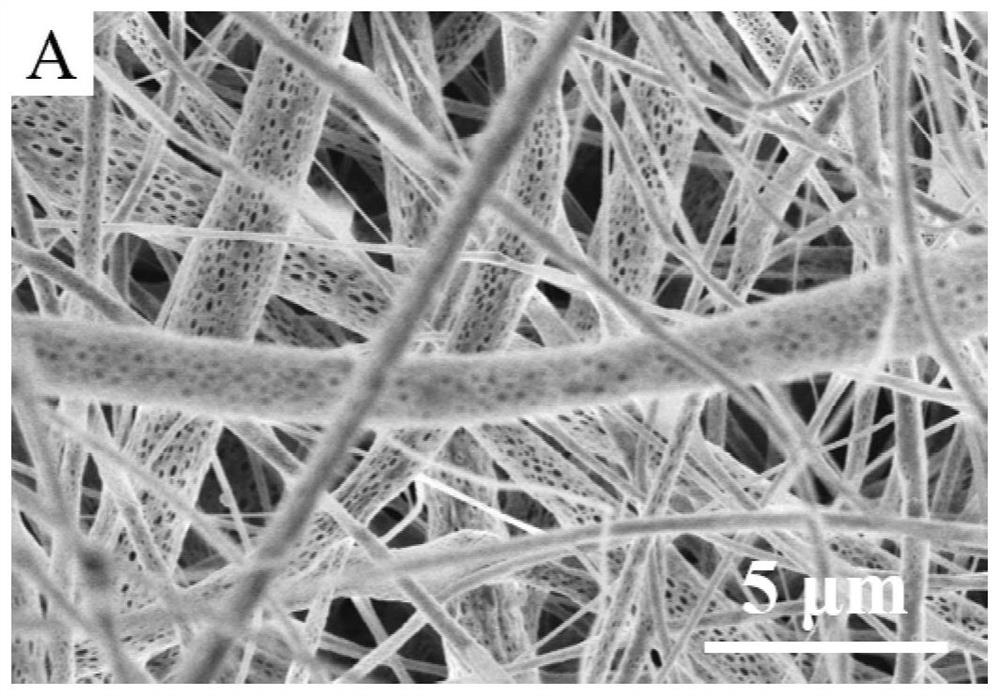

[0036] (1) Dissolve 1.0g of polylactic acid particles in 10mL of dichloromethane (DCM) to obtain a 10% polylactic acid spinning solution, adjust the ambient humidity to 20%, 50%, and 80%, and inject the solution into a 20mL syringe, The electrospinning voltage is 25kV, the flow rate is 1.0mL / h, and the receiving distance is 15cm. The porous PLA nanofibers, that is, the porous polylactic acid nanofibers, are prepared. The morphology of the fibers is observed according to the scanning electron microscope. When the humidity of the electrospinning environment is 80 %, the porosity of the fiber is the highest, the pores are more uniform, and the fiber morphology is as Figure 1a shown.

[0037] (2) Soak the porous polylactic acid nanofiber membrane in 50% ethanol aqueous solution in advance to remove impurities on the surface of the fiber membrane, and then soak...

Embodiment 2

[0042] A preparation method of a preservative film with microbial intelligence self-inhibition, the specific steps are:

[0043] (1) Dissolve 1.0g polylactic acid particles in 10mL dichloromethane to obtain 10% polylactic acid spinning solution, adjust the ambient humidity to 80%, inject the solution into a 20mL syringe, and the electrospinning voltage is 25kV, and the flow rate is 1.0 mL / h, the receiving distance is 15cm, and the porous polylactic acid nanofibers are prepared.

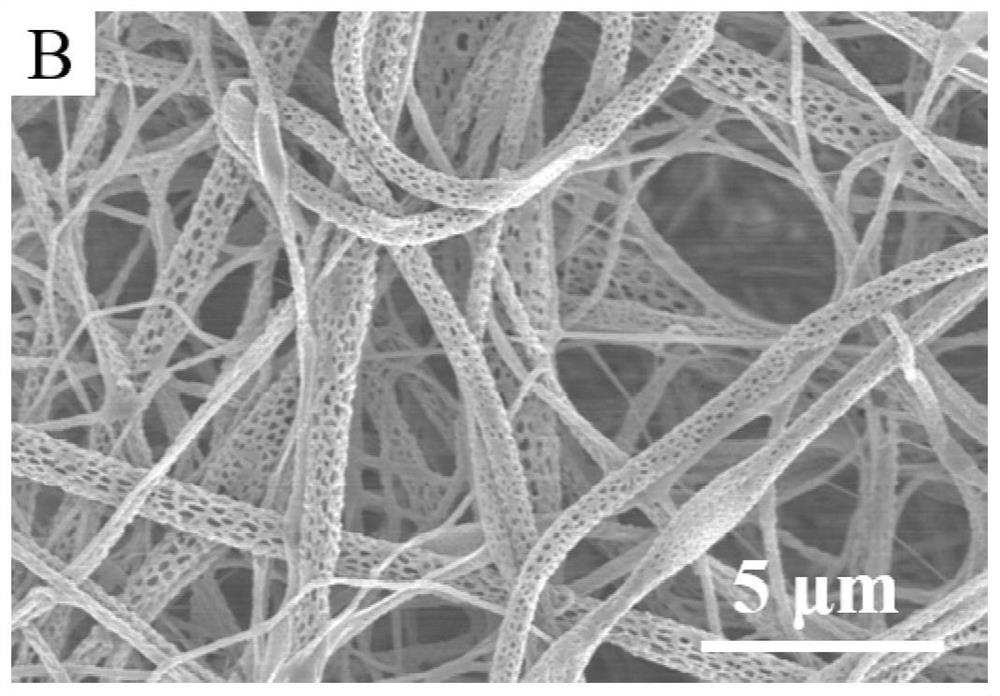

[0044] (2) Soak the porous polylactic acid nanofiber membrane in 50% ethanol aqueous solution in advance to remove impurities on the surface of the fiber membrane, and then soak it in 0.2M NaOH solution for 10min, 20min, 30min, 40min, 50min, 60min, 70min, 80min ,90min (50℃), when the treatment time is 60min with NaOH, the fiber still maintains the complete morphology, when the treatment time exceeds 60min, the fiber morphology is damaged.

[0045] (3) Activate the NaOH-treated nanofibers in the EDC / N...

Embodiment 3

[0049] A preparation method of a preservative film with microbial intelligence self-inhibition, the specific steps are:

[0050] (1) Dissolve 1.0g polylactic acid particles in 10mL dichloromethane (DCM) to obtain 10% polylactic acid spinning solution, adjust the ambient humidity to 80%, inject the solution into a 20mL syringe, and the electrospinning voltage is 25kV, The flow rate was 1.0mL / h, and the receiving distance was 15cm, and porous PLA nanofibers were prepared.

[0051] (2) Soak the porous polylactic acid nanofiber membrane in 50% ethanol aqueous solution in advance to remove impurities on the surface of the fiber membrane, and then soak in 0.2M NaOH solution for 60min (50°C).

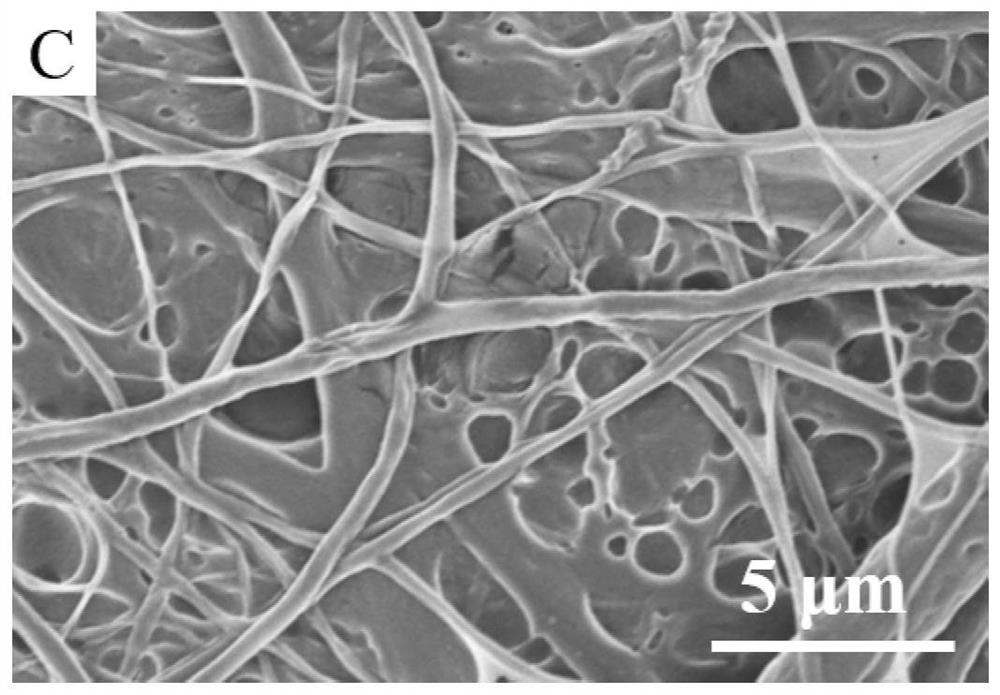

[0052] (3) Activate the NaOH-treated nanofibers in the EDC / NHS mixed solution. In the EDC / NHS mixed solution, the concentration of EDC is 6 mg / mL, and the concentration of NHS is 4 mg / mL. Stir slowly at room temperature for 12 hours, wash with water for 3 times to remove unreacted EDC / NHS. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com