Fuel additive, preparation method thereof and fuel composition

A fuel additive and additive technology, which is applied to fuel additives, fuels, liquid carbon-containing fuels, etc., can solve the problems of difficult control of experimental parameters, complex composition of anti-wear agents, and general anti-wear properties, and achieves simple preparation process and production cost. Low cost and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

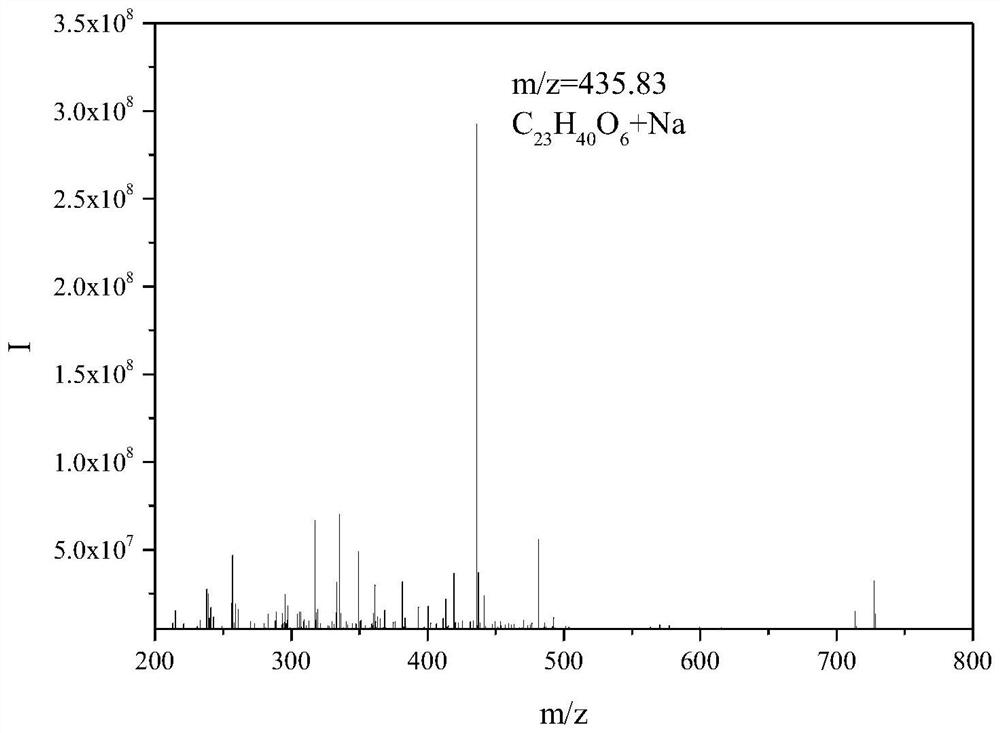

Image

Examples

Embodiment 1

[0077] 500g methyl ricinoleate (mass fraction is 75%, Shanghai Aladdin Biochemical Technology Co., Ltd.) and 128.5g succinic anhydride (succinic anhydride, mass fraction is 99%, Shanghai Aladdin Biochemical Technology Co., Ltd.) In a 1000mL reactor equipped with an electric stirrer, a thermometer, a reflux condenser and a nitrogen inlet tube (the molar ratio of ricinoleic acid methyl ester to succinic anhydride is about 1:0.8). Introduce nitrogen, slowly heat to 80°C while stirring, and reflux for 4 hours.

[0078] As shown in Reaction Formula 1.

[0079]

[0080] The obtained succinate-based ricinoleic acid methyl ester was 624.1 g, and the yield was about 71.3%.

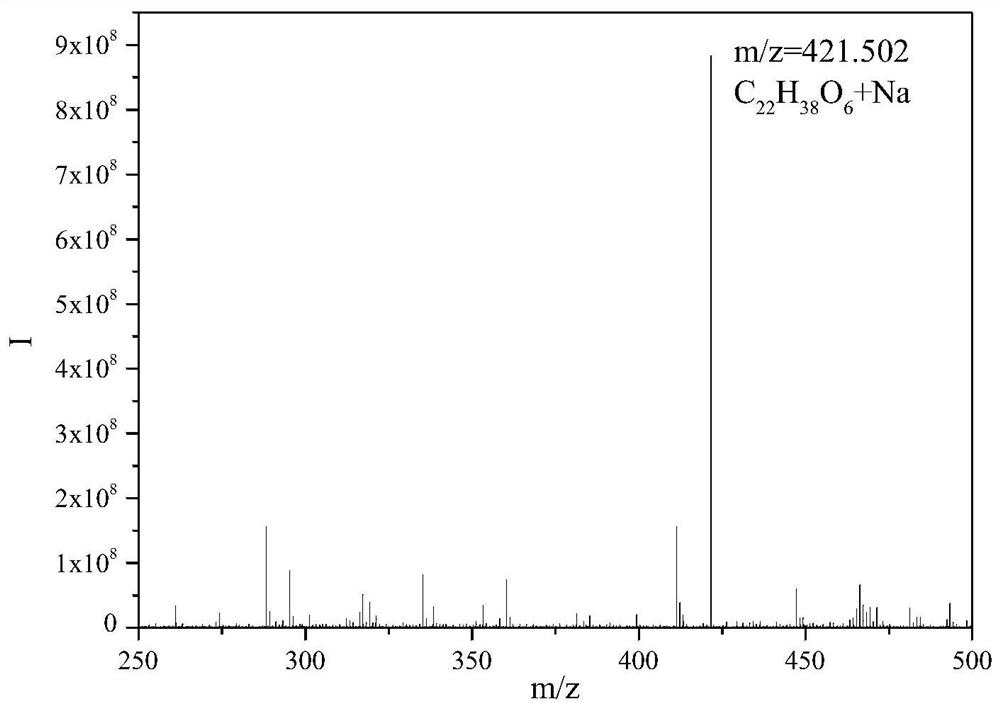

Embodiment 2

[0082] 500g methyl ricinoleate (mass fraction is 75%, Shanghai Aladdin Biochemical Technology Co., Ltd.) and 245.7g succinic acid (massfraction is 99.5%, Shanghai Aladdin Biochemical Technology Co., Ltd.) Stirrer, thermometer, reflux condenser and nitrogen inlet tube in the 1000mL reactor (the molar ratio of ricinoleic acid methyl ester to succinic acid is about 1:1.3). Introduce nitrogen gas, slowly heat to 120°C while stirring, and reflux for 10 hours. Excess succinic acid was removed by distillation under reduced pressure to obtain 739.9 g of succinate-based ricinoleic acid methyl ester, with a yield of about 76.7%.

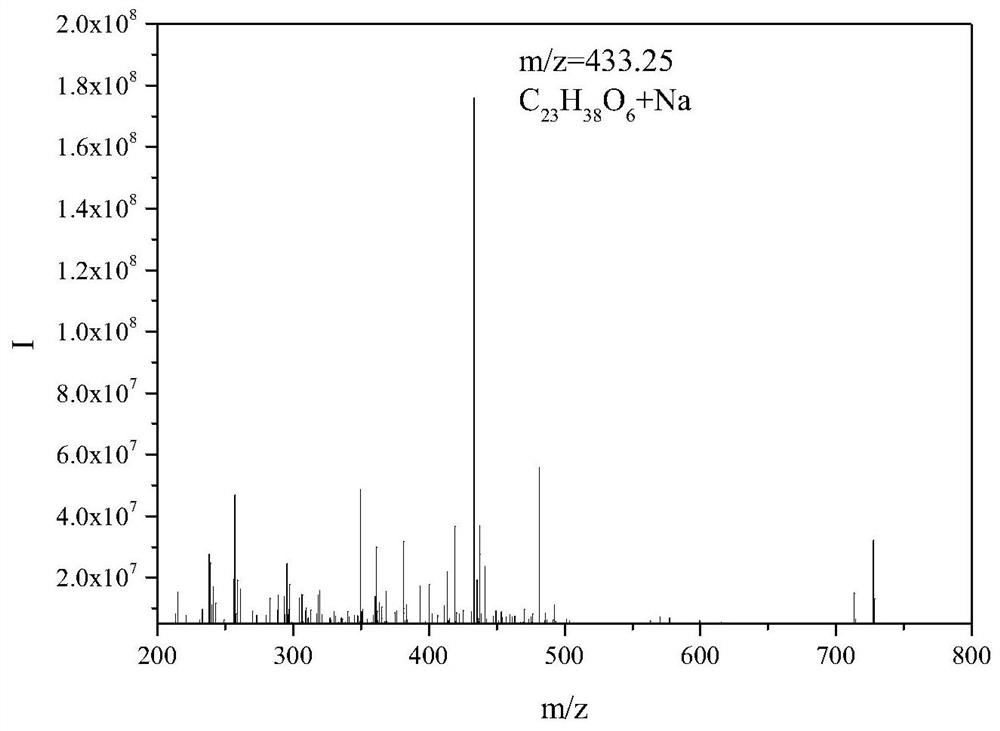

Embodiment 3

[0084] Castor oil biodiesel was obtained according to the preparation method of castor oil biodiesel provided in Example 1 of patent CN101974372A. 1000g castor oil biodiesel (castor oil biodiesel fatty acid ester composition is shown in Table 2) and 801.5g succinic anhydride (succinic anhydride, mass fraction is 99%, Shanghai Aladdin Biochemical Technology Co., Ltd.) In a 3000mL reactor with an electric stirrer, a thermometer, a reflux condenser and a nitrogen inlet pipe, the molar ratio of castor oil biodiesel (the molecular weight is considered to be the same as that of ricinoleic acid methyl ester, based on 312.5g / mol) to succinic anhydride is about 1:2.5, feed nitrogen, heat and stir to raise the temperature to 100°C, reflux for 8 hours, remove excess succinic anhydride by distillation under reduced pressure, and obtain about 1706.1 g of the product, with a yield of about 92.8%.

[0085] Table 2 Castor oil biodiesel fatty acid ester composition

[0086] Fatty ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com