Removable thermal visbreaking adhesive tape and preparation method thereof

An adhesive tape and removal technology, which is applied in the direction of film/sheet adhesive, adhesive, adhesive type, etc., can solve the problems of laborious tape removal, affecting use, and easy to leave residual glue, etc., to achieve Ease of removal, improved peeling efficiency, and improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

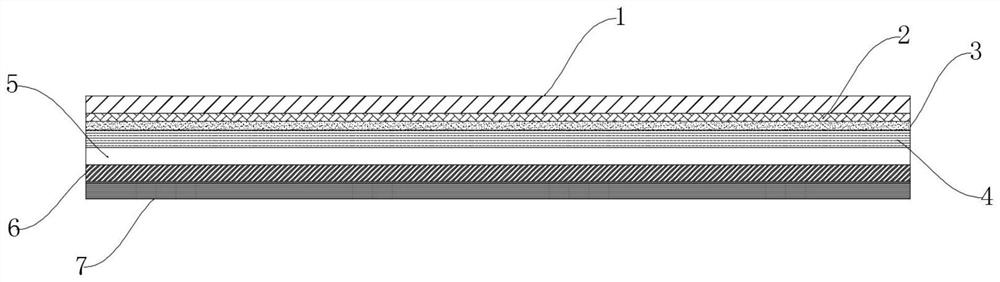

[0030] Such as figure 1 As shown, a removable heat-adhesive adhesive tape according to the present invention includes a substrate layer 1, a vulcanized layer 2, an adhesive layer 3, a first release film 4, and a heat-conducting layer arranged in sequence from top to bottom. 5. The thermal detackification layer 6 and the second release film 7; the vulcanization layer 2 is coated on the lower surface of the substrate layer 1, and the adhesive layer 3 is coated on the upper surface of the first release film 4, And the substrate layer 1 is bonded with the first release film 4 through the adhesive layer 3, and the heat conduction layer 5 is coated on the lower surface of the first release film 4, and the first release film 4 is connected with the second release film. The molded films 7 are connected by a thermal detackification layer 6 .

[0031] Wherein, the thickness of the thermal detackification layer 6 is 30 microns to 50 microns; the substrate layer 1 is a structure made of ...

Embodiment 2

[0034] This embodiment discloses a preparation method of a removable heat-adhesive adhesive tape on the basis of embodiment 1, comprising the following steps:

[0035] Step 1. Preparation of acrylate copolymer: Weigh 20% of isooctyl acrylate, 60% of butyl acrylate, 10% of methyl methacrylate, and 10% of glycidyl methacrylate according to the mass ratio, and pass through the initiator Polymerization reaction obtains acrylate copolymer;

[0036] Step 2. Pretreatment of white carbon black: Weigh a certain amount of white carbon black, dry it in a drying oven at 70-80°C for 4-6 hours, take it out, and grind it into a uniform particle size of 30-50 microns with a grinder. particles;

[0037] Step 3. Preparation of thermal viscose-reducing adhesive: Weigh 100 parts of acrylate copolymer, 1 part of crosslinking curing agent, 5 parts of foaming agent, 0.2 part of white carbon black, 20 parts of organic solvent and 1 part of color paste according to parts by weight. part, stir and mi...

Embodiment 3

[0041] The preparation method of the removable thermal adhesive tape disclosed in this example is basically the same as Example 2, the only difference is that the raw material ratio of acrylate copolymer is: isooctyl acrylate 30%, butyl acrylate 30%, methyl methacrylate 20%, glycidyl methacrylate 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com