A kind of oca optical glue and its preparation method and application and optical film based on it

A technology of optical glue and hydroxyl, which is applied in the direction of optics, optical components, adhesives, etc., can solve the problems of weak adhesion and low initial viscosity of explosion-proof film glue, and achieve the effects of fast reaction rate, fast curing speed and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

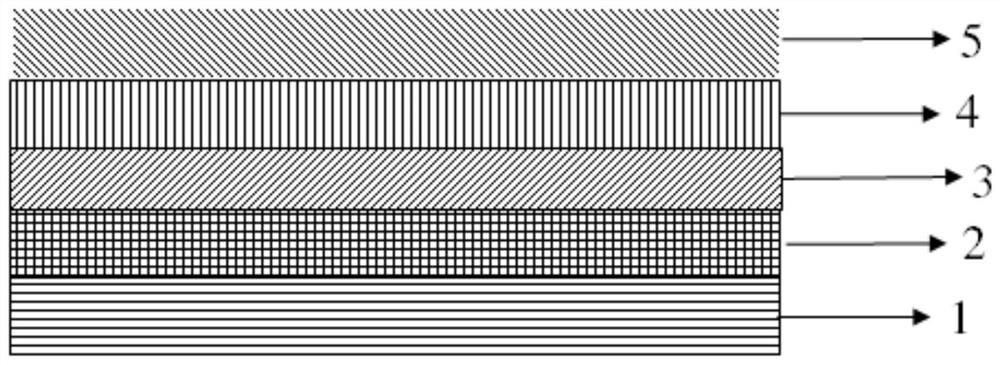

Image

Examples

Embodiment 1

[0043] This embodiment provides an optical glue for OCA of an explosion-proof film, which is prepared from the following components: 100 g of acrylic resin; 0.2 g of hydrogenated rosin resin; 8 g of isobornyl methacrylate; 2-hydroxy-2-methanol 1.2 g of methyl-1-phenyl-1-propanone and 0.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0044]The acrylic resin is prepared by reacting the following components: 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane formal acrylate, 2g lauryl acrylate, 5g isobornyl methacrylate ester, 4 g of glycidyl methacrylate, 5 g of acryloylmorpholine, 0.3 g of 1-hydroxycyclohexyl phenyl ketone and 0.7 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0045] The synthetic technique of described acrylic resin is:

[0046] (1) 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane methylal acrylate, 2g lauryl acrylate, 5g isobornyl methacrylate, 4g glycidyl methacrylate Esters, 5g ...

Embodiment 2

[0051] This embodiment provides an optical glue for OCA of an explosion-proof film, which is prepared from the following components: 100 g of acrylic resin; 0.2 g of hydrogenated rosin resin; 8 g of isobornyl methacrylate; 2-hydroxy-2-methanol 1.2 g of methyl-1-phenyl-1-propanone and 0.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0052] The acrylic resin is prepared by reacting the following components: 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane formal acrylate, 1g lauryl acrylate, 5g isobornyl methacrylate ester, 4 g of glycidyl methacrylate, 5 g of acryloylmorpholine, 0.3 g of 1-hydroxycyclohexyl phenyl ketone and 0.7 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0053] The synthetic technique of described acrylic resin is:

[0054] (1) 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane formal acrylate, 1g lauryl acrylate, 5g isobornyl methacrylate, 4g glycidyl methacrylate Esters, 5g o...

Embodiment 3

[0059] This embodiment provides an optical glue for OCA of an explosion-proof film, which is prepared from the following components: 100 g of acrylic resin; 0.2 g of hydrogenated rosin resin; 8 g of isobornyl methacrylate; 2-hydroxy-2-methanol 1.2 g of methyl-1-phenyl-1-propanone and 0.2 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide.

[0060] The acrylic resin is prepared by reacting the following components: 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane formal acrylate, 2g lauryl acrylate, 5g isobornyl methacrylate ester, 4 g of glycidyl methacrylate, 2 g of acryloylmorpholine, 0.3 g of 1-hydroxycyclohexyl phenyl ketone and 0.7 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0061] The synthetic technique of described acrylic resin is:

[0062] (1) 4g vinyl acetate, 75g n-butyl acrylate, 3g acrylic acid, 2g cyclotrimethylolpropane methylal acrylate, 2g lauryl acrylate, 5g isobornyl methacrylate, 4g glycidyl methacrylate Esters, 2g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com