High-performance premixed concrete and preparation method thereof

A ready-mixed concrete, high-performance technology, applied in the field of concrete, can solve the problems of cracks in building components, poor durability, and inability to use for a long time, and achieve the effects of uniform distribution of hydration products, improved durability, and improved impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

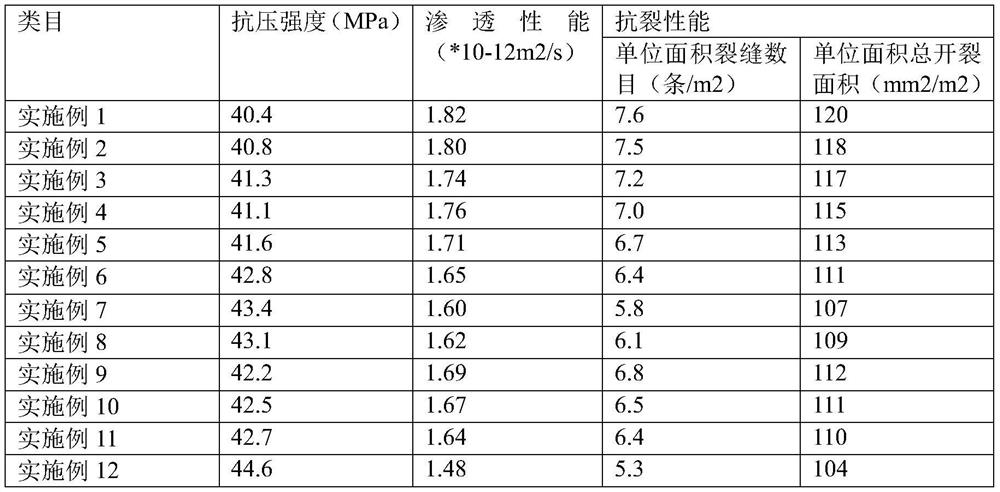

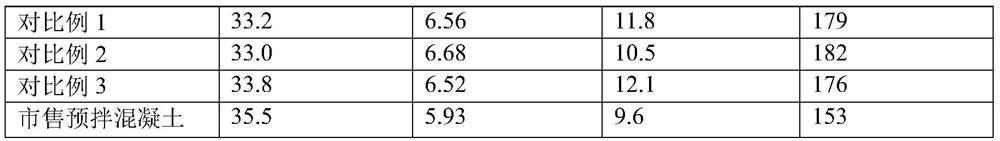

Examples

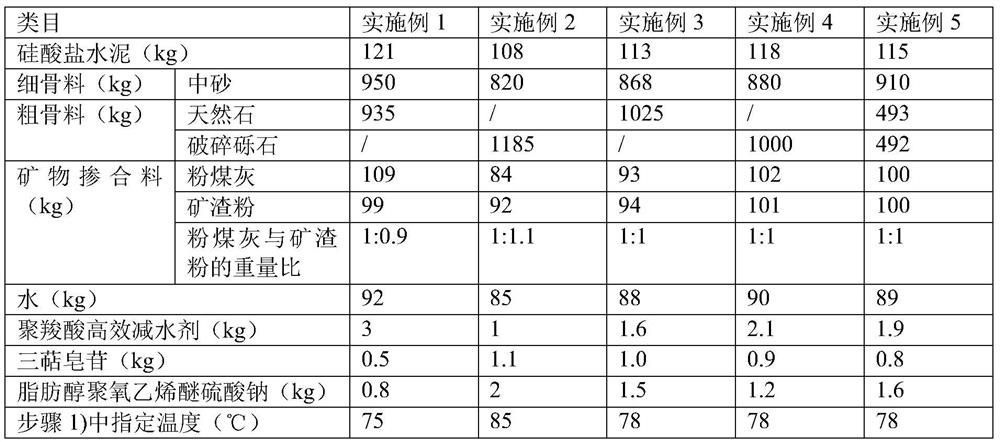

Embodiment 1-5

[0040] A high-performance ready-mixed concrete prepared from concrete mixture, which includes the following raw materials: Portland cement, fine aggregate, coarse aggregate, mineral admixture, water, polycarboxylate high-efficiency reducer Aqueous agent, triterpene saponin, fatty alcohol polyoxyethylene ether sodium sulfate.

[0041] Among them, the fine aggregate is medium sand.

[0042] Coarse aggregate is one or more mixtures of natural stone and crushed gravel with an average particle size of 12mm.

[0043] The mineral admixture is fly ash and slag powder, and the weight ratio of fly ash and slag powder is 1: (0.9-1.1).

[0044] Refer to Table 2 for the specific selection and dosage of the above various raw materials.

[0045] The preparation method of high-performance ready-mixed concrete comprises the following steps:

[0046] Step 1): Heating triterpene saponins, fatty alcohol polyoxyethylene ether sodium sulfate, and water at a specified temperature, and stirring at...

Embodiment 6

[0054] A high-performance ready-mixed concrete, the difference from Example 5 is that the polycarboxylate superplasticizer is CC-AI polycarboxylate superplasticizer.

Embodiment 7

[0056] A kind of high-performance ready-mixed concrete, and the difference with embodiment 5 is that, in step 3), also put into with sulfamate superplasticizer, sulfamate superplasticizer and polycarboxylic acid superplasticizer The weight ratio of the agent is 0.5:1, that is, the input amount of the sulfamate superplasticizer is 0.95kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com