Impermeable self-compacting concrete and preparation method thereof

A self-compacting concrete and compacting technology, applied in the field of concrete preparation, can solve the problems of cracks, damage, poor splitting tensile strength and high capillary porosity on the surface, reduce the initial resistance and viscosity coefficient, and improve the compactness. , the effect of small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

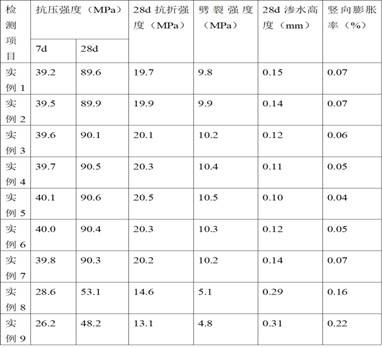

example 1

[0043] Mix a urea solution with a concentration of 1 mol / L and an aluminum sulfate solution with a concentration of 0.05 mol / L at a molar ratio of 20:1 to obtain a mixed solution, and mix the obtained mixed solution with methyl amyl alcohol at a mass ratio of 50:1 Then put it into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, control the filling degree to 50%, conduct a hydrothermal reaction at 90°C for 12 hours, cool and filter to obtain a filter cake, and use pure water and absolute ethanol to ultrasonically cross-wash respectively 5 times, freeze-dried and then calcined at a high temperature in a box-type resistance furnace for 3 hours, and then discharged to obtain ultra-fine spherical alumina; weighed rice husks, washed them, put them in a carbonization furnace, and kept carbonized at 400°C for 2 hours to obtain carbonized rice husks , mix carbonized rice husk and iron powder with a mass ratio of 100:1, put them into a vacuum furnace, pass argon into...

example 2

[0045] Mix a urea solution with a concentration of 1 mol / L and an aluminum sulfate solution with a concentration of 0.05 mol / L at a molar ratio of 20:1 to obtain a mixed solution, and mix the obtained mixed solution with methyl amyl alcohol at a mass ratio of 50:1 Then put it into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, control the filling degree to 50%, conduct a hydrothermal reaction at 90°C for 12 hours, cool and filter to obtain a filter cake, and use pure water and absolute ethanol to ultrasonically cross-wash respectively 5 times, freeze-dried and then calcined at a high temperature in a box-type resistance furnace for 3 hours, and then discharged to obtain ultra-fine spherical alumina; weighed rice husks, washed them, put them in a carbonization furnace, and kept carbonized at 400°C for 2 hours to obtain carbonized rice husks , mix carbonized rice husk and iron powder with a mass ratio of 100:1, put them into a vacuum furnace, pass argon into...

example 3

[0047]Mix a urea solution with a concentration of 1 mol / L and an aluminum sulfate solution with a concentration of 0.05 mol / L at a molar ratio of 20:1 to obtain a mixed solution, and mix the obtained mixed solution with methyl amyl alcohol at a mass ratio of 50:1 Then put it into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, control the filling degree to 50%, conduct a hydrothermal reaction at 90°C for 12 hours, cool and filter to obtain a filter cake, and use pure water and absolute ethanol to ultrasonically cross-wash respectively 5 times, freeze-dried and then calcined at a high temperature in a box-type resistance furnace for 3 hours, and then discharged to obtain ultra-fine spherical alumina; weighed rice husks, washed them, put them in a carbonization furnace, and kept carbonized at 400°C for 2 hours to obtain carbonized rice husks , mix carbonized rice husk and iron powder with a mass ratio of 100:1, put them into a vacuum furnace, pass argon into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com