Lightweight heat-preservation paper-gypsum integral wall material

A technology of gypsum and gypsum board, which is applied in building materials, building components, buildings, etc., can solve the problems of high thermal conductivity, general thermal insulation performance, unfavorable building energy conservation and environmental protection, and achieve crack resistance, impermeability and Good antifreeze performance and good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

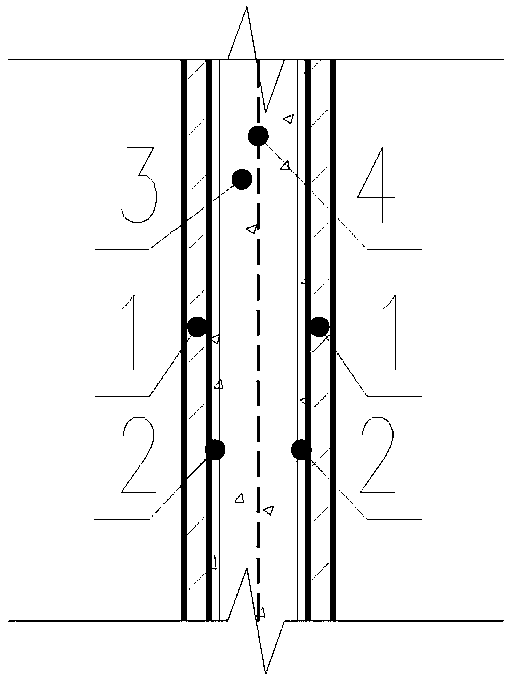

[0013] A light-weight thermal insulation paper-faced gypsum integral wall material, which includes (1) 40mm thick paper-faced gypsum board, (2) polyurethane adhesive, and (3) 100mm-thick strength grade not less than C20 foam concrete from the inside to the outside Embedded with (4) 400X400 steel wire mesh, (2) polyurethane adhesive, (1) 40mm thick lightweight paper-faced gypsum board.

[0014] figure 1 It is a structural schematic diagram of a specific embodiment of a lightweight thermal insulation paper-faced gypsum integral wall material of the present invention.

[0015] The meanings of reference marks in the figure: (1)—40mm thick lightweight gypsum board, (2)—polyurethane adhesive, (3)—100mm thick strength grade not less than C20 foam concrete, (4)—400X400 steel wire Mesh, (2)—polyurethane adhesive, (1)—40mm thick lightweight paper-faced gypsum board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com