Universal preparation method of nitrogen-phosphorus co-doped carbon-loaded transition metal phosphide

A transition metal, co-doping technology, applied in the preparation/purification of carbon, phosphide, chemical instruments and methods, etc., can solve the problems of low flash point, easy volatility, and high toxicity of organic phosphine compounds and organic phosphine compounds, Achieve the effect of important application value, low price and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example is a universal preparation method for nitrogen-phosphorus co-doped carbon-supported transition metal phosphides. The specific process is:

[0032] 1) Disperse 14g of melamine polyphosphate powder in 800mL of deionized water, and ultrasonically treat it to obtain a uniformly dispersed white emulsion;

[0033] 2) Add 0.523g of ruthenium chloride to the white emulsion prepared in step 1), and stir for 2 hours;

[0034] 3) The emulsion in step 2) is separated, washed, dried for 12 hours, and ground into a fine powder;

[0035] 4) Put the powder obtained in step 3) into a porcelain boat, raise the temperature to 800° C. at a rate of 5° C. / min under argon protection, and calcinate for 2.5 hours. After cooling to room temperature, nitrogen and phosphorus co-doped carbon-supported ruthenium phosphide (RuP 2 @NPC).

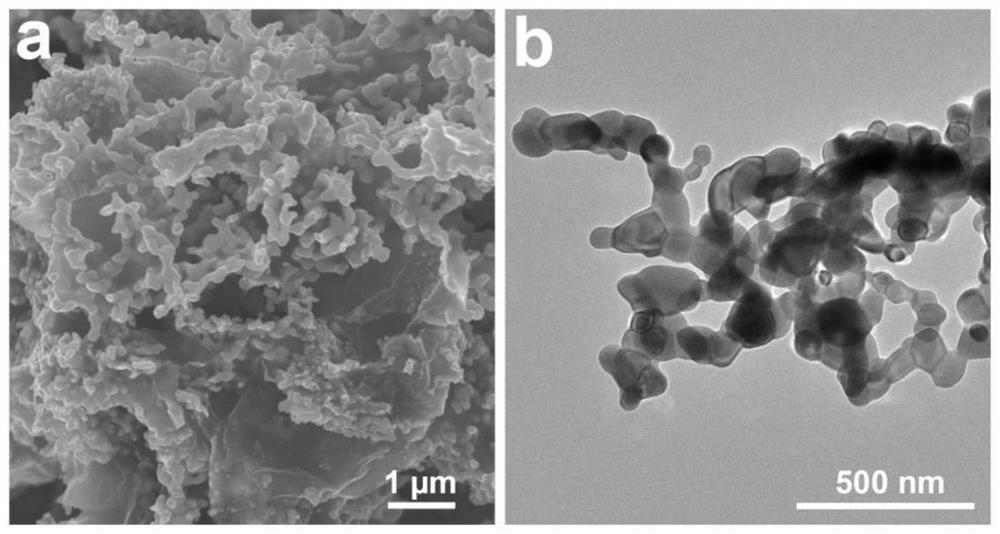

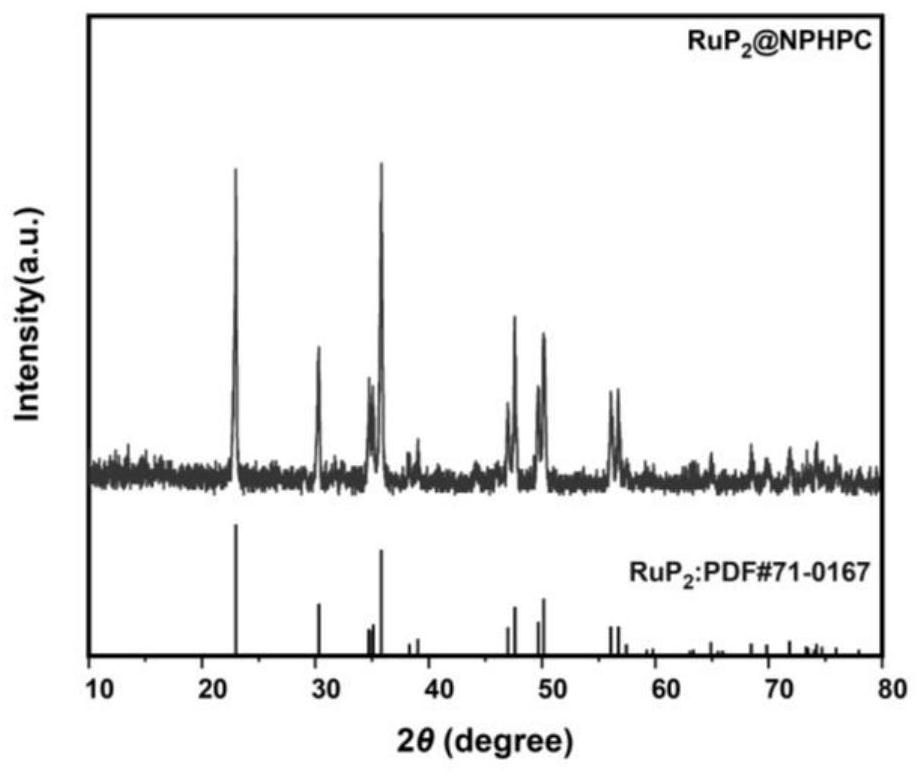

[0036] The product obtained in this embodiment is a coral-like structure, such as figure 1 shown in a and 1b. Through XRD analysis, it can be seen...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] 1) Evenly mix 5g of melamine polyphosphate with 0.25g of tungsten oxide powder;

[0040] 2) Put the powder obtained in step 1) into a porcelain boat, raise it to 900°C at a rate of 5°C / min under the protection of argon and calcinate for 2 hours, and cool to room temperature to obtain nitrogen-phosphorus co-doped carbon-supported tungsten phosphide Materials (WC / WP@NPC).

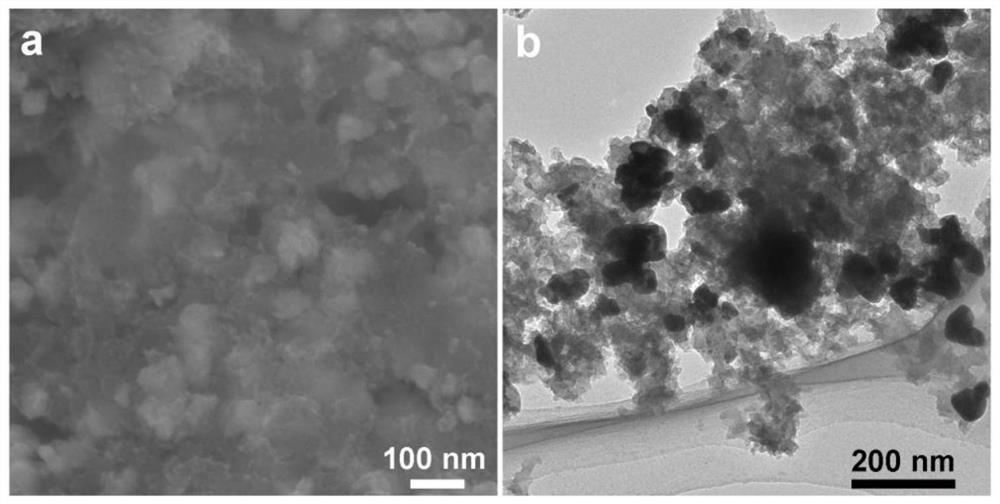

[0041] The product obtained in this example is a composite of nanoparticles and porous carbon, such as image 3 shown. XRD analysis shows that the tungsten oxide raw material is converted into tungsten phosphide after being calcined with melamine polyphosphate, accompanied by the generation of tungsten carbide ( Figure 4 ). According to this example, a nitrogen-phosphorus co-doped carbon-supported tungsten phosphide material was successfully prepared based on the one-step reaction of melamine polyphosphate.

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] 1) Disperse 7g of melamine polyphosphate powder in 400mL of deionized water, and ultrasonically disperse to obtain a uniform white emulsion;

[0045] 2) Add 0.133g of chromium chloride to the emulsion prepared in step 1), and stir for 2h;

[0046] 3) The emulsion in step 2) is separated and washed, then dried at a constant temperature for 12 hours, and then ground into a fine powder;

[0047] 4) Put the powder obtained in step 3) into a porcelain boat, raise it to 1500°C at a rate of 10°C / min under the protection of argon and calcined for 1h, and after cooling to room temperature, a nitrogen-phosphorus co-doped carbon-supported phosphating Chromium material (CrP@NPC).

[0048] The microscopic morphology of the product obtained in this example is a sheet structure, and a large number of nanoparticles are loaded at the same time, such as Figure 5 shown. Through XRD analysis, it can be known that the product phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com