Sound insulation composite material with excellent mechanical property and preparation method thereof

A composite material and performance technology, applied in the field of sound insulation composite materials and their preparation, can solve the problems of complex processing procedures, limited application scope, inability to have both mechanical properties and sound insulation effects, and achieve excellent sound insulation performance, convenient coloring, and shape design. high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

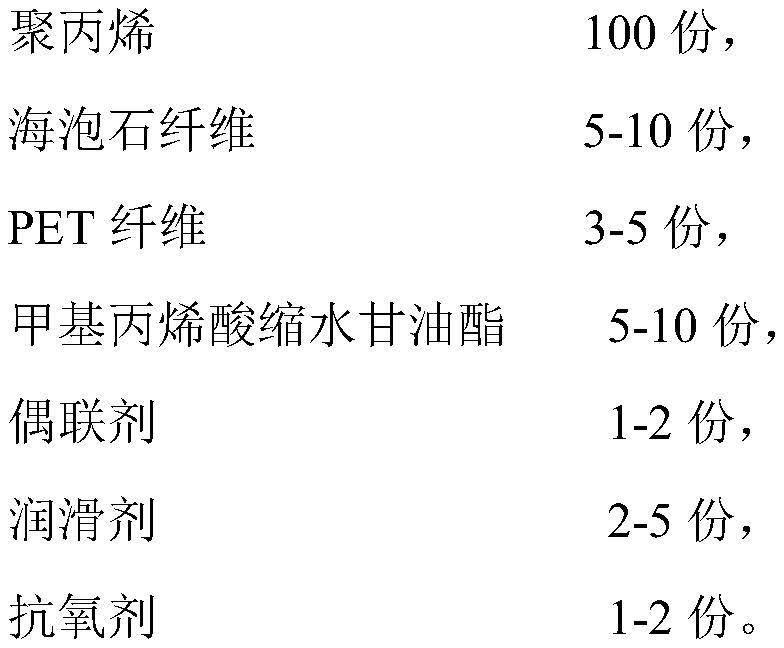

Method used

Image

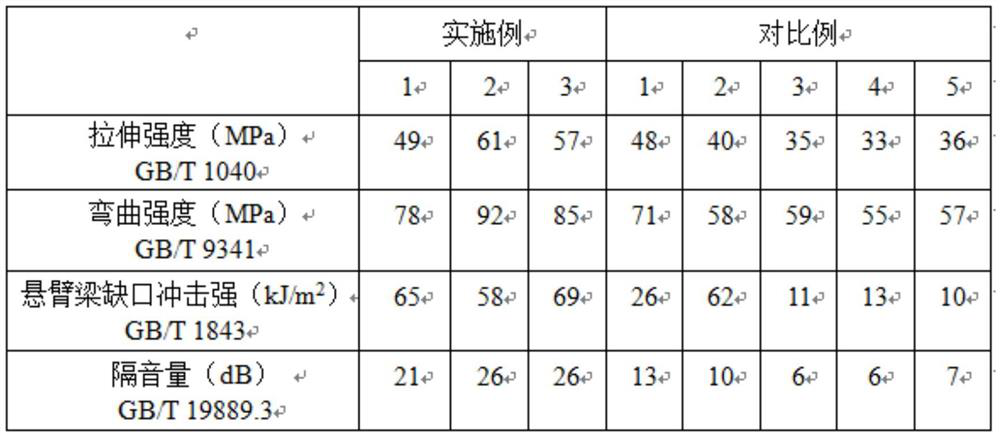

Examples

Embodiment 1

[0023] Mix 100 parts of polypropylene, 5 parts of sepiolite fiber, 3 parts of PET fiber, 5 parts of glycidyl methacrylate, 2 parts of lubricant, 1 part of antioxidant, 1 part of coupling agent KH550, and add to the twin-screw The final product is obtained after kneading, extrusion and cooling in the sheet extruder. Wherein the extrusion temperature of each extrusion zone in the twin-screw extruder is 160°C, 170°C, 180°C, 180°C, 190°C, 200°C, 210°C, 210°C respectively.

Embodiment 2

[0025] Mix 100 parts of polypropylene, 10 parts of sepiolite fiber, 5 parts of PET fiber, 10 parts of glycidyl methacrylate, 5 parts of lubricant, 2 parts of antioxidant, 2 parts of coupling agent KH550, and add to the twin-screw The final product is obtained after kneading, extrusion and cooling in the sheet extruder. Wherein the extrusion temperature of each extrusion zone in the twin-screw extruder is 170°C, 180°C, 190°C, 190°C, 200°C, 210°C, 220°C, 220°C respectively.

Embodiment 3

[0027] Mix 100 parts of polypropylene, 8 parts of sepiolite fiber, 4 parts of PET fiber, 8 parts of glycidyl methacrylate, 3 parts of lubricant, 2 parts of antioxidant, 2 parts of coupling agent KH550, and add to the twin-screw The final product is obtained after kneading, extrusion and cooling in the sheet extruder. Wherein the extrusion temperature of each extrusion zone in the twin-screw extruder is 165°C, 175°C, 185°C, 185°C, 195°C, 205°C, 215°C, 215°C respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com