Solid-phase sintered silicon carbide product and preparation method thereof

A solid-phase sintering, silicon carbide technology, applied in the field of engineering ceramic materials, can solve the problems of difficult automatic production, increased production cost, low production efficiency, etc., and achieves the effects of low cost, reduced processing cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A method for preparing a solid-phase sintered silicon carbide product, comprising the steps of:

[0054] S1. Ingredients: use micron-sized silicon carbide powder with a particle size of 3-10 μm as the main raw material, boron-containing sintering aids with a particle size of 3-10 μm and water-soluble carbon black as solid-phase sintering aids; binder , plasticizer and lubricant as functional additives; wherein, the amount of boron-containing sintering aid is 0.2-0.5wt% of the weight of micron-sized silicon carbide powder, and the amount of water-soluble carbon black is 0.5% of the weight of micron-sized silicon carbide powder. -3wt%; the amount of the binder is 0.5-2wt% of the weight of the micron silicon carbide powder; the plasticizer consists of a high molecular weight plasticizer with a molecular weight of 150,000-200,000 and a low molecular weight plasticizer with a molecular weight of 4000-6000 Composition, the weight ratio of high molecular weight plasticizer and...

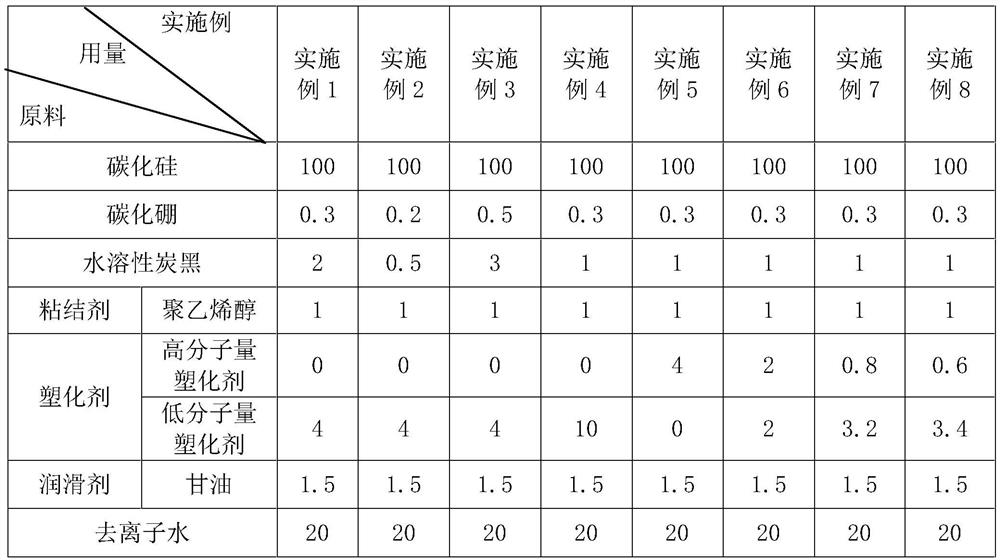

Embodiment 1-8

[0073] The consumption of each raw material in embodiment 1-8 is shown in table 1. As shown in Table 1, the main difference of Examples 1-8 is that the proportioning ratio of raw materials is different.

Embodiment 1

[0075] The preparation method of the silicon carbide product provided in Example 1 is as follows:

[0076] S1. Grinding of raw materials: put 100kg of micron-sized silicon carbide powder and 0.3kg of boron carbide powder into a vertical grinder, and grind them with water as a solvent to obtain a slurry with a particle size of 0.4-0.8μm and a solid content of 45wt%. material;

[0077] S2. Spray granulation: add 1 kg of water-soluble carbon black and 1 kg of binder to the slurry of S1, stir evenly, adopt centrifugal spray granulation, the inlet temperature is 225°C, and the outlet temperature is 98°C to obtain silicon carbide Granulated powder;

[0078] S3. Mixing: Take 100kg of silicon carbide granulated powder prepared by S2, add it to the mixer, then add 4kg of plasticizer, start the mixer, mix the two evenly, then add 20kg of deionized water and 1.5 kg lubricant, stirred evenly to obtain wet powder;

[0079] S4. Stale: put the wet powder under the condition of temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com