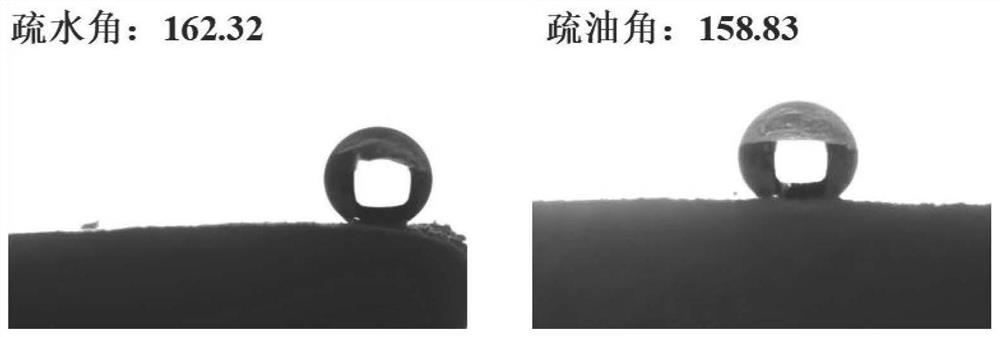

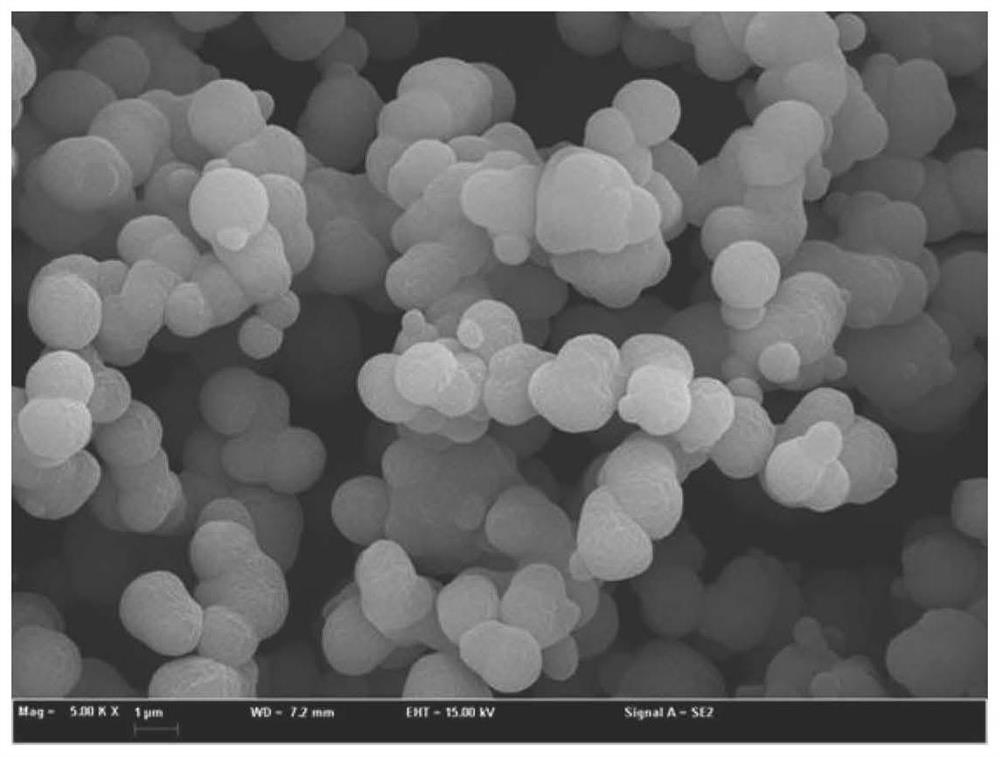

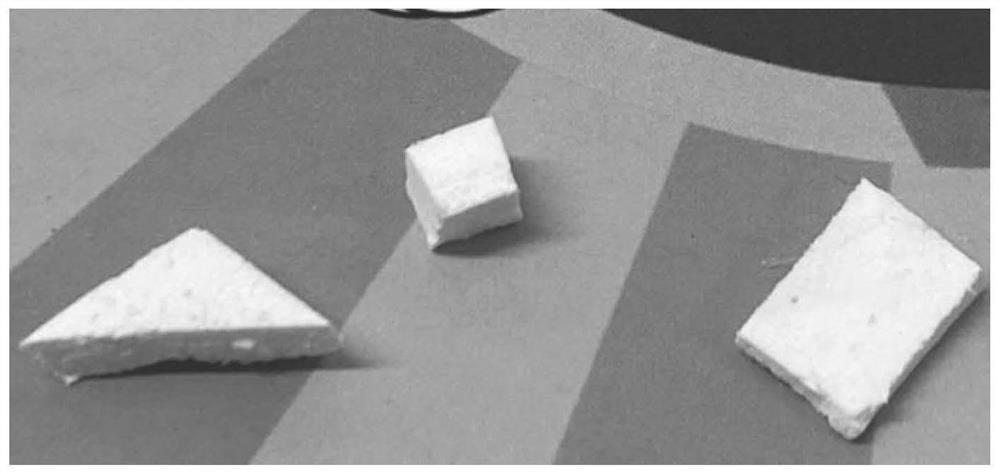

Preparation method of in-situ fluorination modified super-amphiphobic flexible SiO2 aerogel

An aerogel and superamphiphobic technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of limiting the application range of superamphiphobic materials and the amphiphobic properties staying on the surface of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] First, mix 1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane and methyltrimethoxysilane in a molar ratio of 1:1 to form a silicone solution, then add methanol and deionized water to control the organic silicon solution. The molar ratio of silicon solution, methanol, and deionized water is 1:10:8, and stirred for 10 minutes to obtain SiO 2 Sol solution, then add oxalic acid solution, control the pH value of the solution to 2, stir for 30min, then add tetramethylammonium hydroxide, the concentration of tetramethylammonium hydroxide in the mixed solution is 0.01mol / L, under the condition of 40℃ water bath Stir for 10 min. Pour the sol solution into the abrasive tool, seal the film, and place it in a vacuum oven at 50°C for 30 minutes to obtain SiO 2 wet gel. Take it out, place it at room temperature, add isopropanol to the mold of the wet gel to perform solvent replacement on the composite wet gel, replace the aging solution every 12 hours, and replace it 3 times in total to...

example 2

[0029] First, mix 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane and methyltrimethoxysilane in a molar ratio of 1:0.1 to form a silicone solution, then add ethanol and deionized water to control Silicone solution, ethanol, and deionized water in a molar ratio of 1:1:1, and stirred for 20 minutes to obtain SiO 2 Sol solution, then add hydrochloric acid solution, control the pH value of the solution to 3, stir for 40 minutes, then add ammonium hydroxide, the concentration of ammonium hydroxide in the mixed solution is 0.1mol / L, stir for 30 minutes in a water bath at 50°C. Pour the sol solution into the mold, seal the film, and place it in a vacuum oven at 60°C for 30 minutes to obtain SiO 2 wet gel. Take it out, place it at room temperature, add ethanol to the mold of the wet gel to perform solvent replacement on the composite wet gel, replace the aging solution every 12 hours, and replace it 5 times in total to obtain a silica gel. The resulting gel samples were subjected to CO...

example 3

[0031] First, mix 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane and methyltriethoxysilane in a molar ratio of 1:10 to form a silicone solution, then add isopropanol, deionized Water, control the molar ratio of organic silicon solution, isopropanol, and deionized water at 1:20:10, stir for 20 minutes, and obtain SiO 2 Sol solution, then add hydrofluoric acid solution, control the pH of the solution to 2, stir for 60 minutes, then add ammonium fluoride solution, the concentration of ammonium fluoride in the mixed solution is 0.1mol / L, and stir for 20 minutes in a 60°C water bath. Pour the sol solution into the mold, seal the film, and place it in a vacuum oven at 60°C for 30 minutes to obtain SiO 2 wet gel. Take it out, place it at room temperature, add isopropanol to the mold of the wet gel to perform solvent replacement on the composite wet gel, replace the aging solution every 24 hours, and replace it 5 times in total to obtain a silica gel. The resulting gel samples were su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com