Graphene heat conduction gasket edge covering process and edge-covered graphene heat conduction gasket

A heat-conducting gasket and graphene technology, which is applied in the wrapping process of graphene heat-conducting gaskets and the field of wrapping graphene heat-conducting gaskets, can solve problems such as short circuits, powder dropping, and damage to electronic products, and achieve improved stability and work Long life, improvement of powder drop problem, excellent thermal conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0038] The graphene thermal pad adopts the following preparation method:

[0039] Place the first layer of graphene film flat on the operating table, evenly coat a layer of adhesive on the graphene film, then place the second layer of graphene film on the first layer of graphene film and coat evenly The second layer of adhesive, reciprocating until stacked to the target height to obtain the graphene film block;

[0040] Open some through holes on the obtained graphene film block, the axial direction of the through hole is along the direction of the graphene film stack and run through both sides of the graphene film block, and the through holes are distributed in an array on the graphene block;

[0041]The carbon fiber filaments are soaked from the adhesive and then inserted into the opened through holes, so that the carbon fiber filaments fill the entire through hole along the length direction, and the graphene-carbon fiber filament three-dimensional structure is obtained afte...

Embodiment 1-8

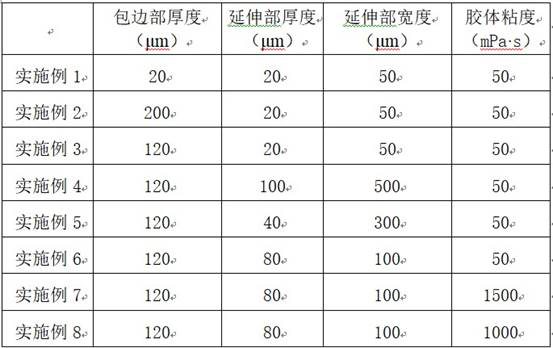

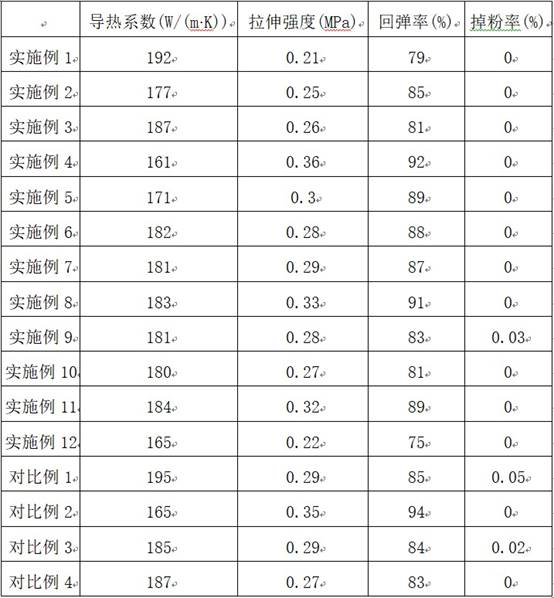

[0051] Embodiment 1-8 discloses a kind of wrapping graphene heat conduction gasket, adopts following preparation process:

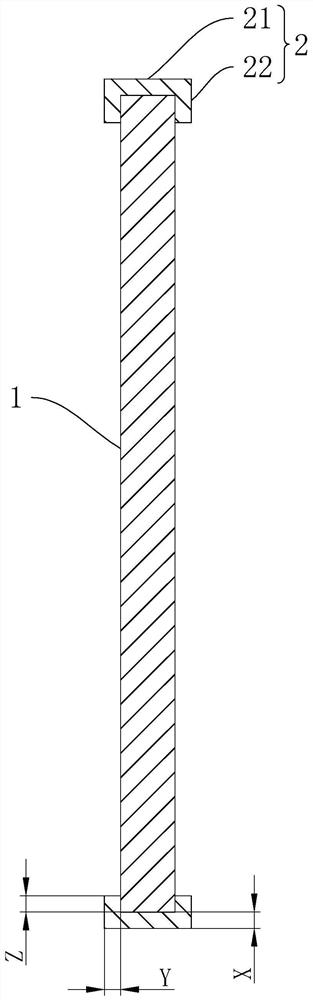

[0052] Use a precision dispenser to evenly coat a layer of colloid on the side walls around the thickness direction of the graphene thermal pad obtained in Preparation Example 1 to form an edge layer, and the colloid is bonded to the side walls around the graphene thermal pad. Partially solidified to form a wrapping part, and a part extending from the wrapping part is attached to the upper and lower sides of the graphene thermal pad and solidified to form an extension part.

[0053] Among them, the colloid is silicone rubber, the colloid coating method is high-precision glue dispensing machine dispensing, and the colloid curing method is heat curing. See Table 1 for the viscosity of the colloid and the specification parameters of each part after the wrapping layer is cured and formed. In Table 1, "thickness of hemming part" is attached figure 1 The X sh...

Embodiment 9

[0057] This embodiment discloses an edge-wrapped graphene thermally conductive gasket. The preparation process is: a layer of colloid is coated around the graphene thermally conductive gasket obtained in Preparation Example 1, the colloid is silicone rubber, and the viscosity of the colloid is 10mPa·s. The colloid curing method is thermal curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com