A kind of benzoxazine nitrile-based resin sandwich structure foam and preparation method thereof

A benzoxazine nitrile-based resin technology, applied in the field of polymer foam, can solve the problems such as the preparation method of nitrile-based resin sandwich structure foam, and achieve the effects of broad industrial application prospect, convenient equipment and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

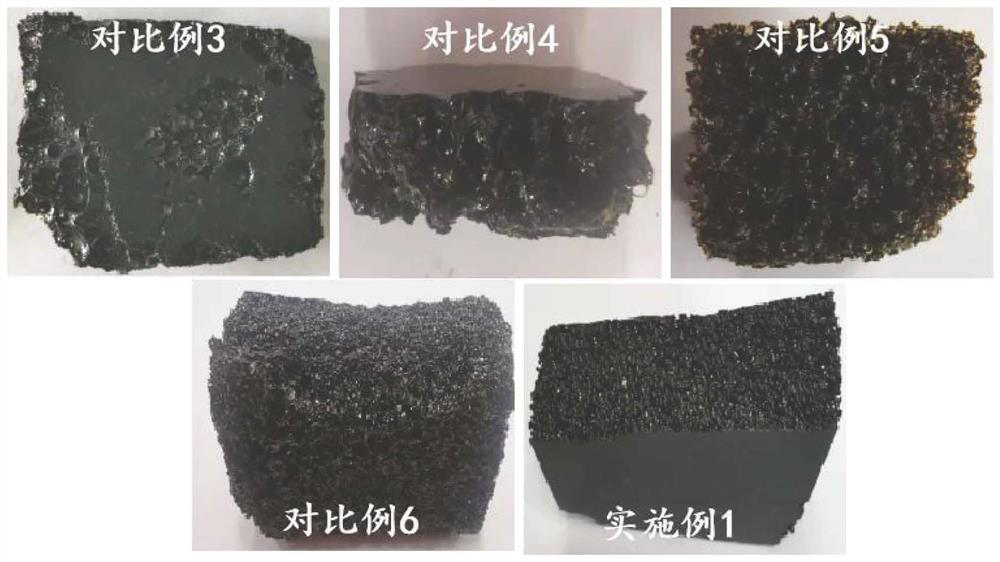

Embodiment 1

[0044] Bisphenol A type nitrile resin sandwich structure foam containing benzoxazine ring: (1) mixing and drying: at room temperature, Tween-80 (2.5g) was added to deionized water (20g), and then added Azodicarbonamide (0.25g) and bisphenol A type nitrile resin (22.5g) containing benzoxazine rings were mixed for 30min under mechanical stirring (200r / min) and ultrasonic (100W) to obtain a viscous The liquid was then transferred to a watch glass and dried at 80°C / 12h to obtain a golden yellow powder. (2) Overturning and foaming: put the above powder in a mold and foam at 150°C for 2 hours. During the foaming process, turn the mold up and down once every 2 minutes. (3) Static curing: 200°C / 1h; 250°C / 1h for curing; after cooling and demoulding, a bisphenol A-type nitrile resin sandwich structure foam containing a benzoxazine ring is obtained.

Embodiment 2

[0046] Bisphenol A type nitrile resin sandwich structure foam containing benzoxazine ring: (1) mixing and drying: at room temperature, Tween-60 (0.2g) was added to deionized water / ethanol (5g / 5g) Add azodicarbonamide (0.1g) and bisphenol A-type nitrile resin (9.8g) containing benzoxazine rings, place in a ball mill and grind and mix for 8 hours to obtain a paste-like liquid, then transfer Transfer to a watch glass and dry at 60°C / 12h to obtain a golden yellow powder. (2) Overturning and foaming: the above powder is placed in a cylindrical mold and foamed at 200°C for 0.5h. During the foaming process, the mold is turned over once every 3 minutes. (3) Static solidification: solidify at 240° C. / 1 h; after cooling and demolding, a bisphenol A-type nitrile-based resin sandwich structure foam containing a benzoxazine ring is obtained.

Embodiment 3

[0048] Bisphenol A type nitrile resin sandwich structure foam containing benzoxazine ring: (1) mixing and drying: at room temperature, Tween-40 (1.2g) was added to deionized water (20g), and then added Azodicarbonamide (1.0g) and bisphenol A type nitrile-based resin (18.8g) containing benzoxazine ring were mixed in ball milling for 8h to obtain a viscous liquid, which was then transferred to a watch glass and kept at 80°C / Dry for 12 hours to obtain a golden yellow powder. (2) Flip foaming: put the above powder in a mold and foam at 140°C for 6 hours. During the foaming process, flip the mold up and down once every 3 minutes. (3) Static curing: 200°C / 1h; 250°C / 1h; 300°C / 1h for curing; after cooling and demolding, a bisphenol A-type nitrile resin sandwich structure foam containing benzoxazine rings is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com