Light guide plate and preparation process thereof

A preparation process and technology of light guide plate, applied in the field of optical transmission, can solve the problems of high temperature resistance, yellowing of PS materials, affecting the service life of products, etc., and achieve the effects of soft light, slowing down brightness difference, and inhibiting yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

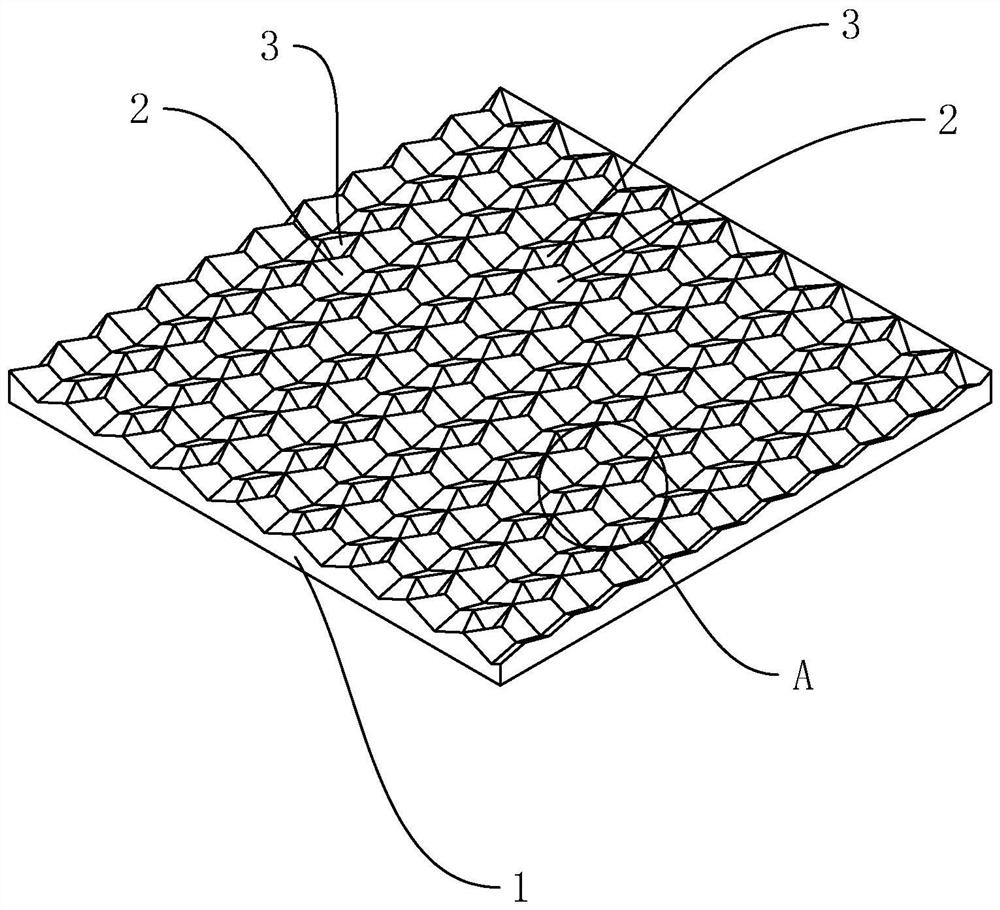

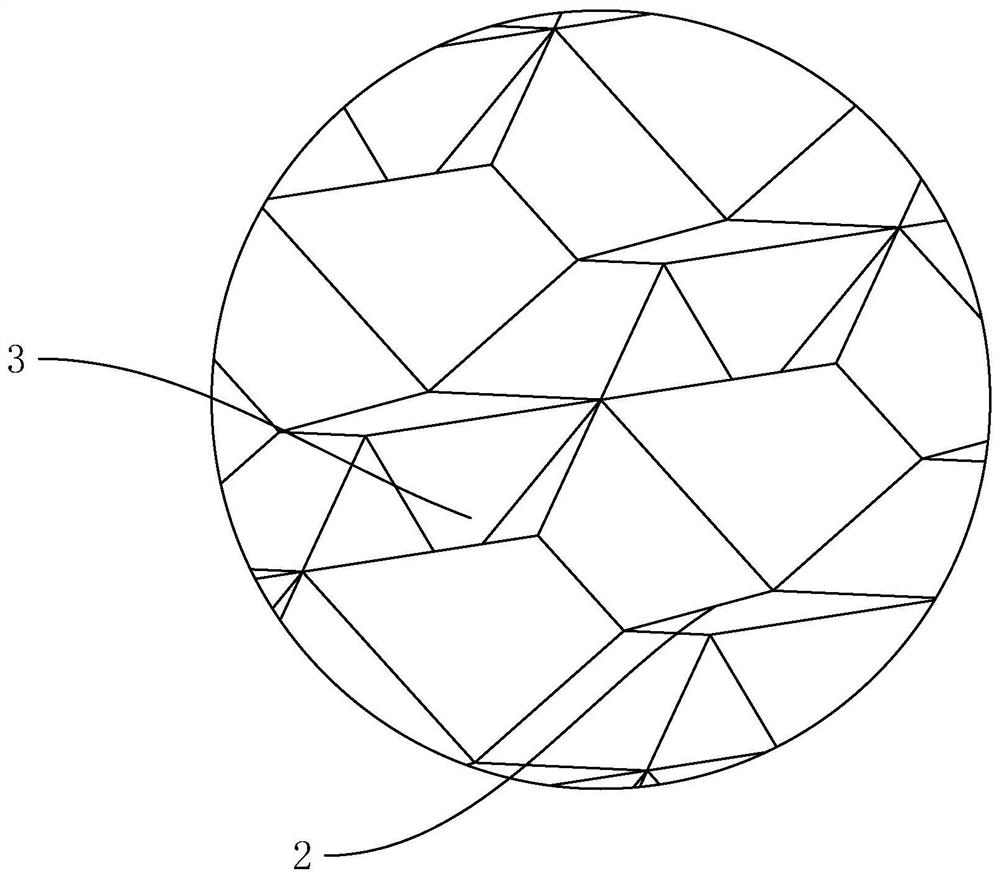

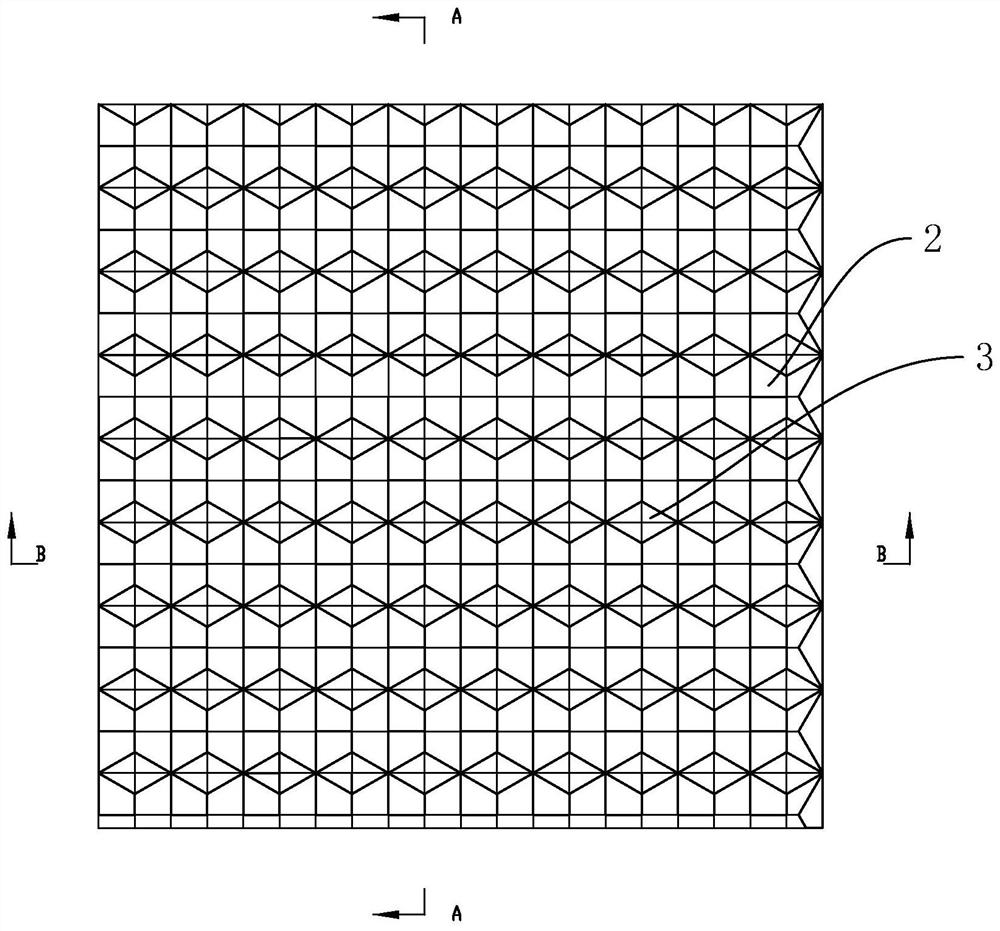

[0052] Embodiment one: if Figure 1 to Figure 3 As shown, a light guide plate includes a substrate 1 integrally extruded, one side of the substrate 1 is recessed to form light guide ribs 2 distributed in an array in the form of regular polygonal pyramids, and adjacent light guide ribs 2 are formed with Diffusion point 3 with diamond-shaped cross section, content of substrate 1 by weight percentage includes:

[0053] Polystyrene 94.5-97.5%;

[0054] Light shielding agent 2-4%;

[0055] Antioxidant 0.1-0.5%;

[0056] Anti-yellowing agent: 0.2-0.8%;

[0057] Light guide powder: 0.1-0.3%;

[0058] Colorant: 0.1-0.2%.

[0059] Polystyrene is made of general polystyrene material (GPPS), and the light shielding agent is nano-inorganic titanium dioxide after drying. Specifically, the nano-inorganic titanium dioxide is dried by heat-insulating pad microwave drying technology, and the antioxidant is Ethylene bis(oxyethylene)bis[3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate], the an...

Embodiment 2

[0063] Embodiment 2: A preparation process of a light guide plate, which is used to prepare a light guide plate as in Embodiment 1, and the steps include:

[0064] 1) Weighing, weighing the raw materials according to the ratio;

[0065] 2) mixing, putting the raw materials into the mixer for stirring, and preheating the mixed raw materials;

[0066] 3) Hot melting, the mixed and preheated raw materials are transported to the screw extruder through the vacuum feeder, melted and blended, the temperature is controlled at 180-200°C, and the screw speed is 100-300r / min;

[0067] 4) Die adjustment, adjust the specifications of the extrusion die head according to the thickness and width of the plate required by the customer, adjust the opening size of the extrusion die head through the cylinder or hydraulic cylinder through the stroke controller, and extrude a plate larger than 10 cm as a sample;

[0068] 5) Forming, when measuring the extruded sheet and sewing the specifications re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com