Method for carrying out reductive amination reaction by adopting microchannel reaction device

A technology of microchannel reaction and microreactor, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds from amines, etc., can solve the problems of water and air sensitivity, release of borane and hydrogen, etc., and achieve toxicity And the effects of less pollution, short reaction time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

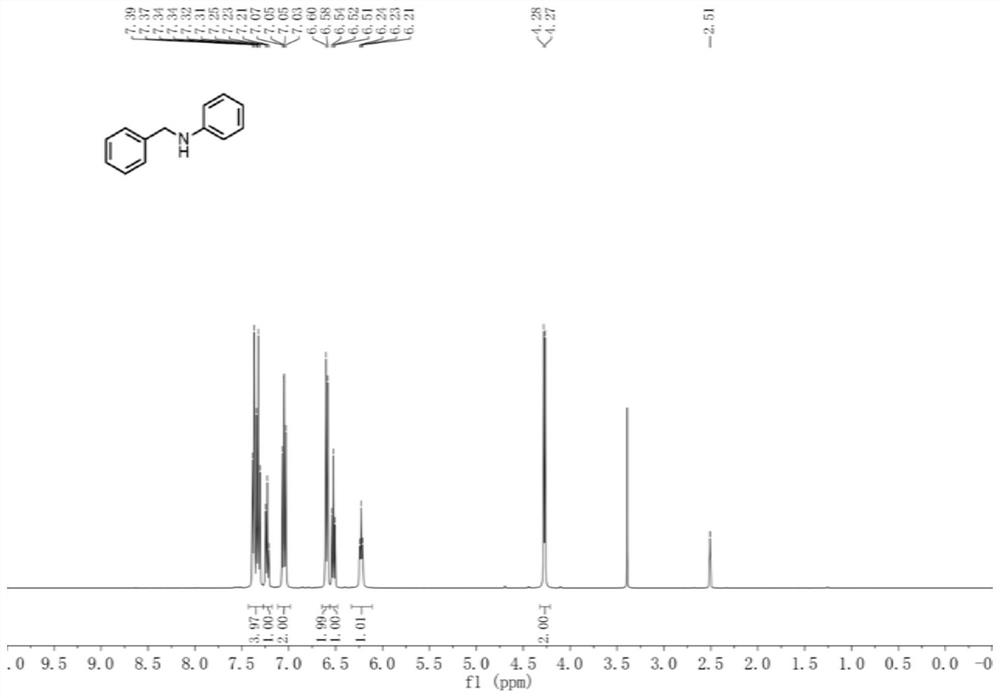

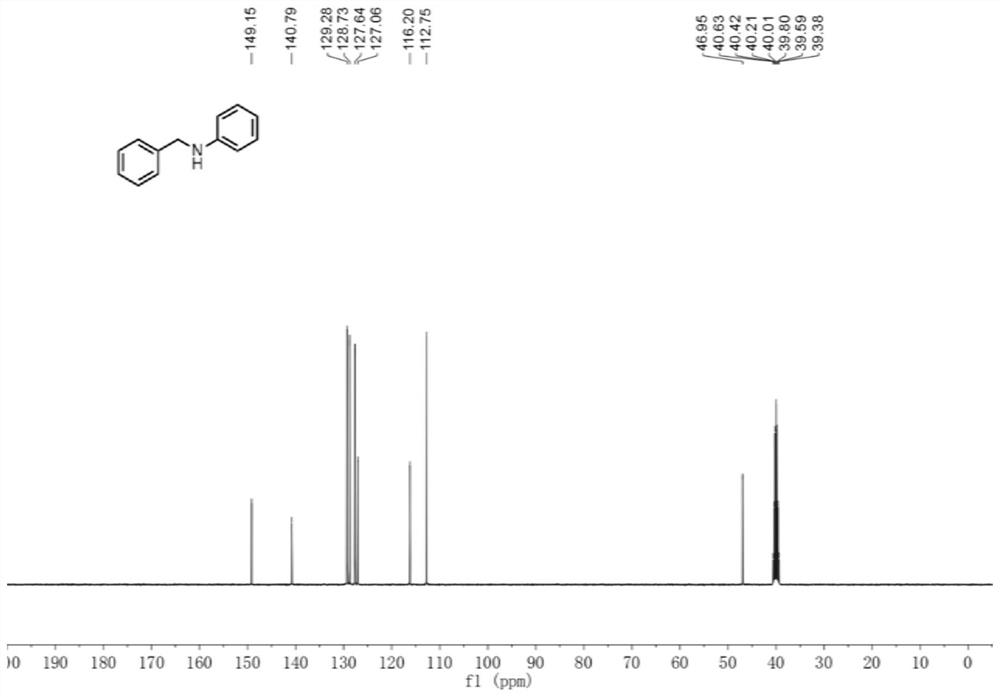

[0035] Embodiment 1: the synthesis of compound 2a

[0036] Inject 1 mmol of benzyl alcohol (I), alcohol oxidase (~700 u), flavin adenine dinucleotide (FAD, 6 μmol, 5 mg), and hydrogen peroxide reductase (0.02 μmol, 4 mg) into syringe A. 10mL aqueous solution, suck air into syringe B, the flow rate of the two samples is 56.25μL min -1 After pumping into the micro-mixer 1 for mixing, then enter the micro-reactor 1 to react at 40°C for 25 minutes. Acetonitrile solution of aniline (1mmol, 0.1M) was injected into syringe C and mixed with the effluent from microreactor 1 through micromixer 2, then entered into microreactor 2 and reacted at 30°C for 8min. Add appropriate amount of water and ethyl acetate to the collected reaction solution for extraction, dry over anhydrous sodium sulfate, and concentrate under reduced pressure to obtain the crude product, which can be separated by column chromatography to obtain the target product 2a with a yield of 75%. NMR image such as figure 1...

Embodiment 2

[0037] Embodiment 2: the synthesis of compound 2b

[0038] Inject 1 mmol of benzyl alcohol (I), alcohol oxidase (~700 u), flavin adenine dinucleotide (FAD, 6 μmol, 5 mg), and hydrogen peroxide reductase (0.02 μmol, 4 mg) into syringe A. 10mL aqueous solution, suck air into syringe B, the flow rate of the two samples is 56.25μL min -1 After being mixed by the micro-mixer 1, enter the micro-reactor 1 to react at 40° C. for 25 min. Acetonitrile solution of 2-methylaniline (1mmol, 0.1M) was injected into syringe C and mixed with the effluent from microreactor 1 through micromixer 2, then entered into microreactor 2 and reacted at 30°C for 8min. Add appropriate amount of water and ethyl acetate to the collected reaction solution for extraction, dry over anhydrous sodium sulfate, and concentrate under reduced pressure to obtain the crude product, which can be separated by column chromatography to obtain the target product 2b with a yield of 76%.

Embodiment 3

[0039] Embodiment 3: the synthesis of compound 2c

[0040] Inject 1 mmol of benzyl alcohol (I), alcohol oxidase (~700 u), flavin adenine dinucleotide (FAD, 6 μmol, 5 mg), and hydrogen peroxide reductase (0.02 μmol, 4 mg) into syringe A. 10mL aqueous solution, suck air into syringe B, the flow rate of the two samples is 56.25μL min -1After being mixed by the micro-mixer 1, enter the micro-reactor 1 to react at 40° C. for 25 min. Acetonitrile solution of 3-chloroaniline (1mmol, 0.1M) was injected into syringe C and mixed with the effluent from microreactor 1 through micromixer 2, then entered into microreactor 2 and reacted at 30°C for 8min. Add appropriate amount of water and ethyl acetate to the collected reaction solution for extraction, dry over anhydrous sodium sulfate, and concentrate under reduced pressure to obtain the crude product, which can be separated by column chromatography to obtain the target product 2c with a yield of 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com