Method for treating flue gas generated in valuable secondary material treatment process

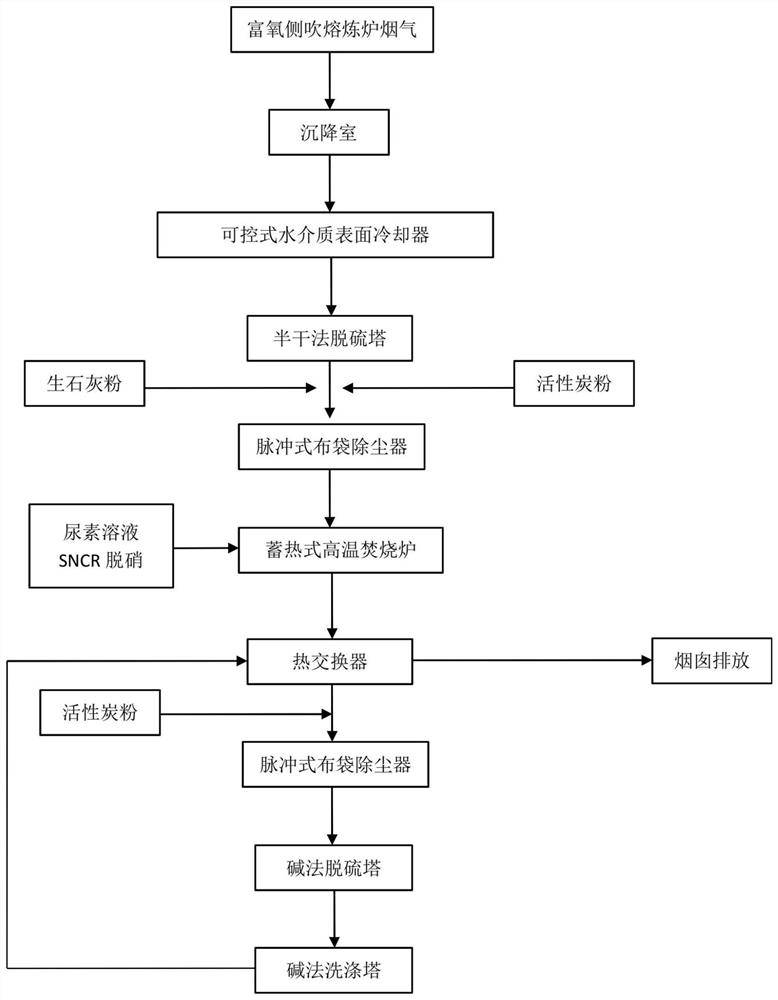

A treatment method and flue gas technology, applied in the direction of gas treatment, combustion method, separation method, etc., can solve the problems of large heat loss, low level of comprehensive recovery, secondary pollution, etc., to achieve good absorption of dioxin and odor, increase Dust removal effect, effect of reducing flue gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Now take an oxygen-enriched smelting furnace factory that processes 120 tons of hazardous wastes such as copper and nickel sludge and electronic waste as an example to further illustrate the implementation of the present invention.

[0052] Hazardous wastes such as copper, nickel sludge and electronic wastes in ton bags after the filing of the five-part form are transported by the truck into the temporary storage of hazardous waste in the factory, and the pellet / brick workshop takes out according to the proportion of various content requirements Materials are batched, stored, dried, and made into ball / brick shapes, and a certain proportion of fuel and flux are put into the oxygen-enriched smelting furnace in sequence. In the furnace, the temperature of the focus area in the furnace is controlled between 1200°C and 1400°C, the flue gas temperature at the furnace shell outlet is between 380°C and 450°C, and the actual flue gas volume measured by the orifice plate flowmeter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com