Antistatic easy-to-clean clothing material and preparation method thereof

An anti-static and easy-to-clean technology, applied in the field of clothing materials, can solve the problems of high viscosity of aqueous solution, high price, poor fiber adsorption, etc., to improve wearing comfort and anti-static properties, improve anti-static ability, and save costs and steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

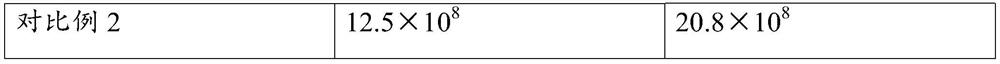

Examples

Embodiment 1

[0040] The following steps prepare the above-mentioned a kind of antistatic easy-to-clean clothing material:

[0041] S1 wrapping the above-mentioned first polyester fiber on the above-mentioned conductive fiber to obtain the above-mentioned antistatic warp yarn;

[0042] The mass ratio of the first polyester fiber to the conductive fiber is 0.5:1.

[0043] S2 Disperse 20 g of the above-mentioned composite particles in an aqueous solution of dichloromethane, immerse the above-mentioned second polyester fiber in the solvent in which the above-mentioned composite particles are dispersed, take it out after 12 hours, dry it for 30 minutes, and wrap the above-mentioned second polyester fiber with the cupro ammonia fiber. On the two polyester fiber, obtain above-mentioned antistatic weft yarn;

[0044] The mass ratio of the cupro ammonia fiber to the second polyester fiber is 1:0.5.

[0045] S3 blending the above-mentioned antistatic warp yarn with the above-mentioned antistatic w...

Embodiment 2

[0047] The following steps prepare the above-mentioned a kind of antistatic easy-to-clean clothing material:

[0048] S1 wrapping the above-mentioned first polyester fiber on the above-mentioned conductive fiber to obtain the above-mentioned antistatic warp yarn;

[0049] The mass ratio of the first polyester fiber to the conductive fiber is 0.5:2.

[0050] S2 Disperse 20 g of the above-mentioned composite particles in an aqueous solution of dichloromethane, immerse the above-mentioned second polyester fiber in the solvent in which the above-mentioned composite particles are dispersed, take it out after 12 hours, dry it for 30 minutes, and wrap the above-mentioned second polyester fiber with the cupro ammonia fiber. On the two polyester fiber, obtain above-mentioned antistatic weft yarn;

[0051] The mass ratio of the cupro ammonia fiber to the second polyester fiber is 2:0.5.

[0052] S3 blending the above-mentioned antistatic warp yarn with the above-mentioned antistatic w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com