Asphalt modifier for self-adhesive waterproof coiled material and preparation method of asphalt modifier

A self-adhesive waterproofing membrane and asphalt modifier technology, applied in the field of asphalt modifiers, can solve the problems of low temperature performance to be improved, complex preparation method, difficult construction, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] All raw materials used in the examples are commercially available unless otherwise specified.

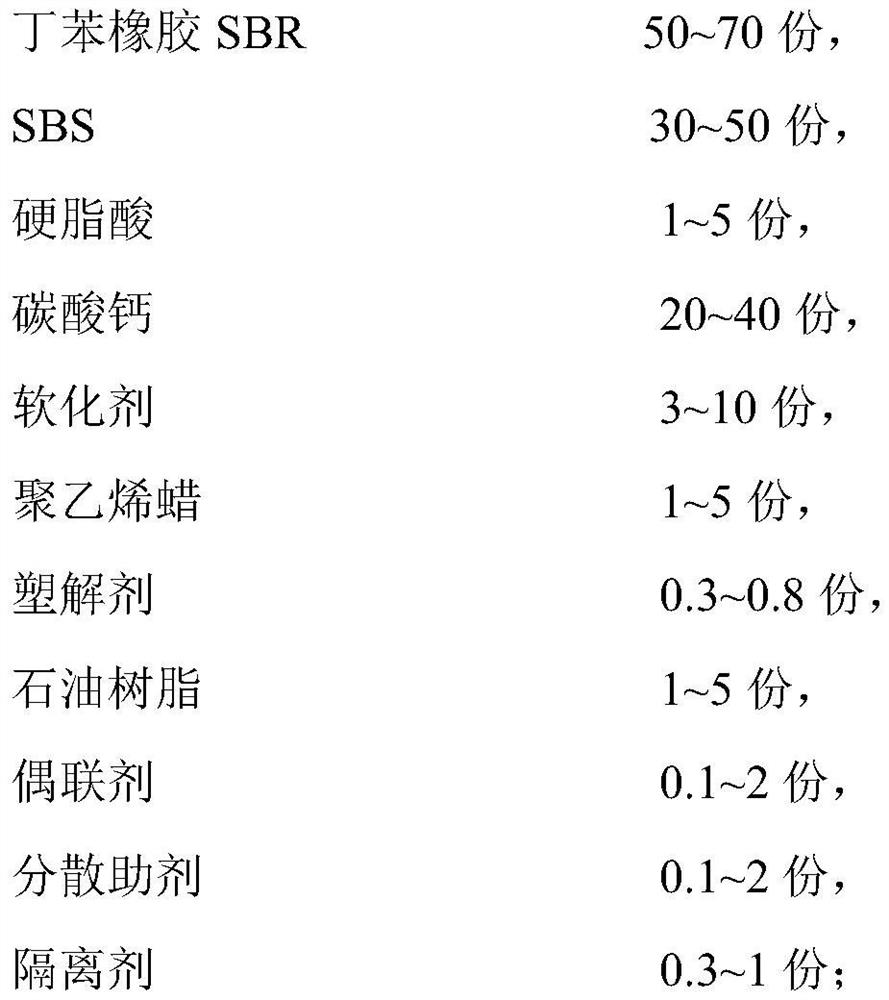

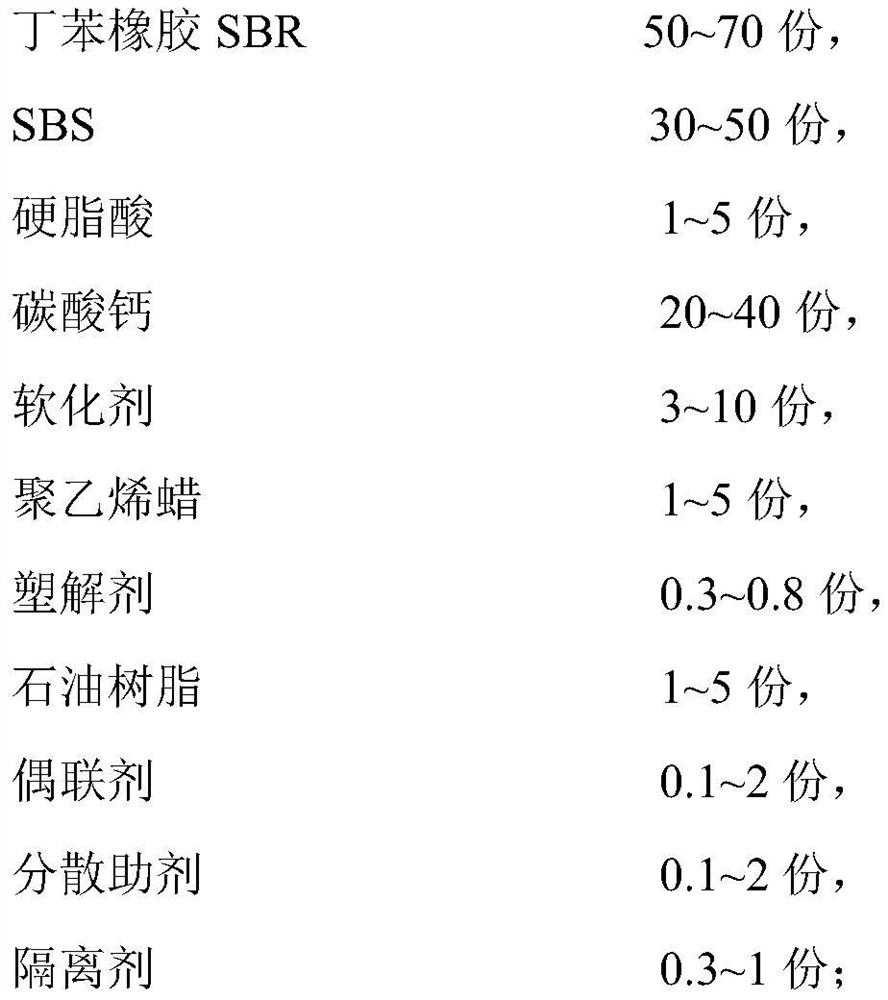

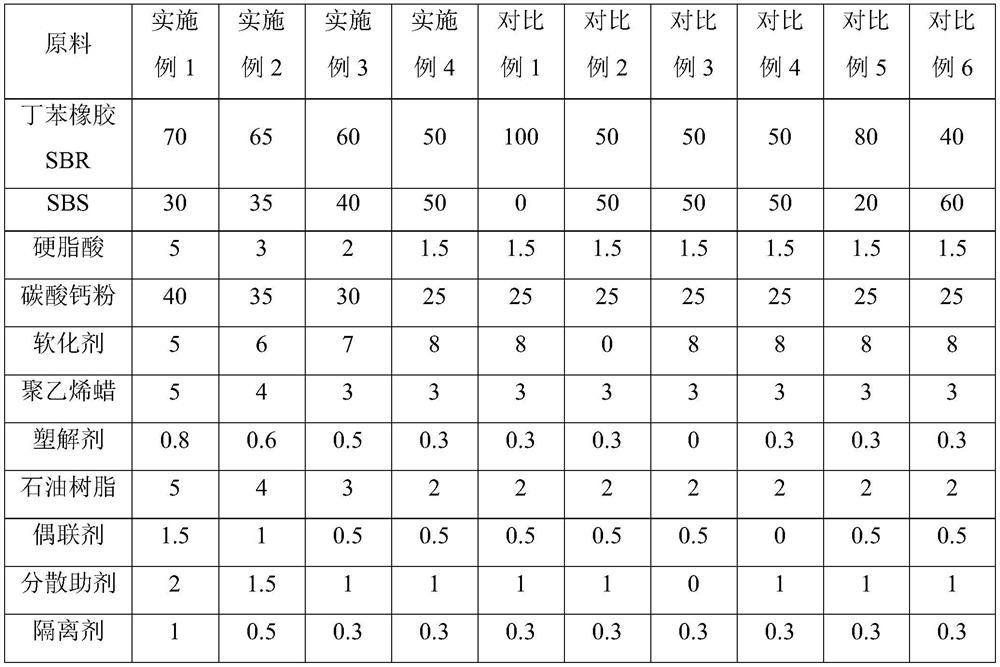

[0029] Examples and comparative examples

[0030] Prepare bitumen modifier by the raw material composition of table 1, wherein softening agent can be any one or more in polycyclic aromatic hydrocarbon rubber oil, naphthenic rubber oil, aromatic base rubber, above several softening agents to product The effect is the same, and mutual replacement has little effect on the performance of the product; the coupling agent can be any one or more of silane coupling agent KH580, silane coupling agent KH550, and silane coupling agent KH792. The effect on the product is the same, and mutual replacement has little effect on the performance of the product. For convenience of comparison, polycyclic aromatic hydrocarbon rubber oil was used as the softener in the examples and comparative examples, KH550 was used as the coupling agent, peptizer A89 was used as the peptizer among the rest of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com