Machine tool grinding fluid negative-pressure filtering circulating treatment system and process thereof

A negative pressure filtration and circulation treatment technology, applied in filtration treatment, sludge treatment, water/sewage treatment and other directions, can solve the problems of decreased filtration effect, large consumption of consumables, multiple working hours, etc., to improve filtration effect and reduce labor costs , the effect of reducing operating hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

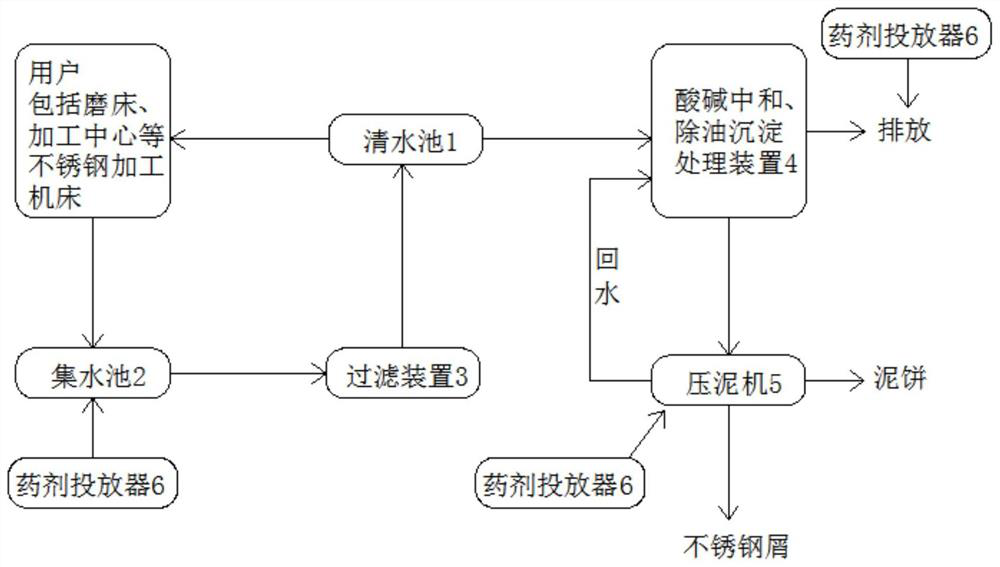

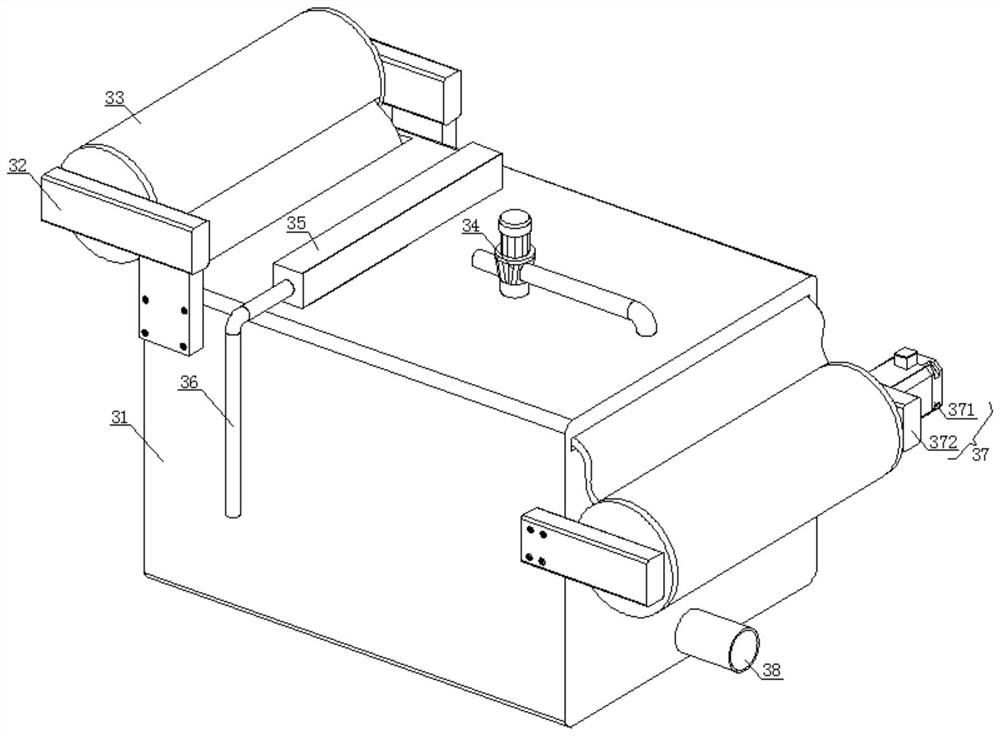

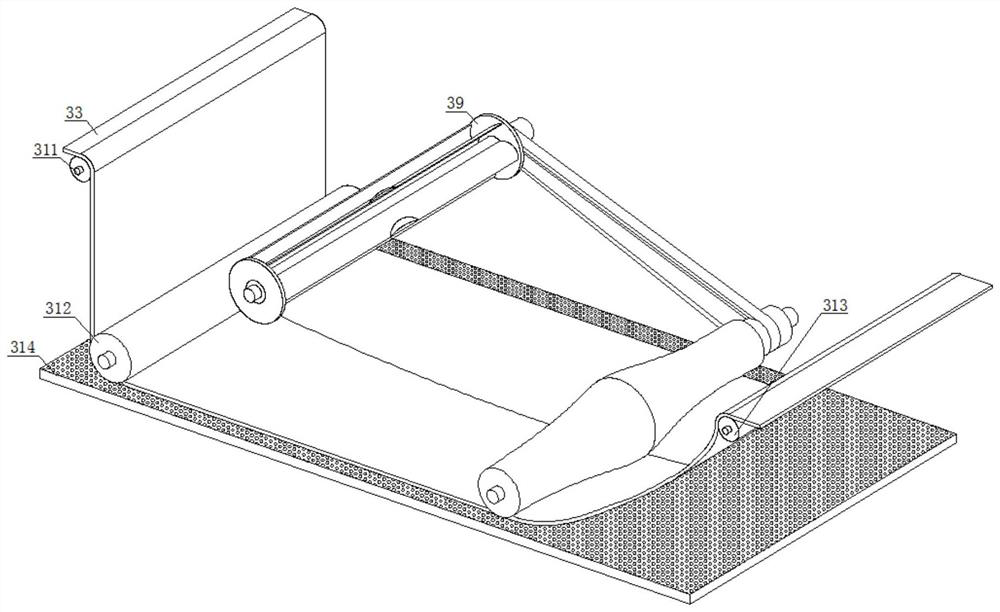

[0042] refer to figure 1 , machine tool grinding fluid negative pressure filtration cycle treatment system, including a clean water tank 1 and a stainless steel processing machine tool connected to the output end of the clean water tank 1, the waste liquid output end of the stainless steel processing machine tool is connected to the input end of the sump 2, and the collection The pool 2 is fed with a small amount of PAM5-10ppm by the drug dispenser 6, which can flocculate small particles of grinding wheel ash and the like to improve the filtration effect. The treated water in the pool 2 is connected to the input port of the filter device 3 through the output port. , is used to carry out secondary filtration to the water of preliminary flocculation, and the output end of the secondary filtration device 3 is connected with the clean water pool 1 again, and the clean water pool 1 neutralizes and removes the treated water with acid and alkali through the output end The input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com