Industrial pump and manufacturing method thereof

A manufacturing method and an industrial technology, applied to chemical instruments and methods, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as increased costs, lower reliability, and lower sealing effects, and achieve improved Effects of cooling effect and parts cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

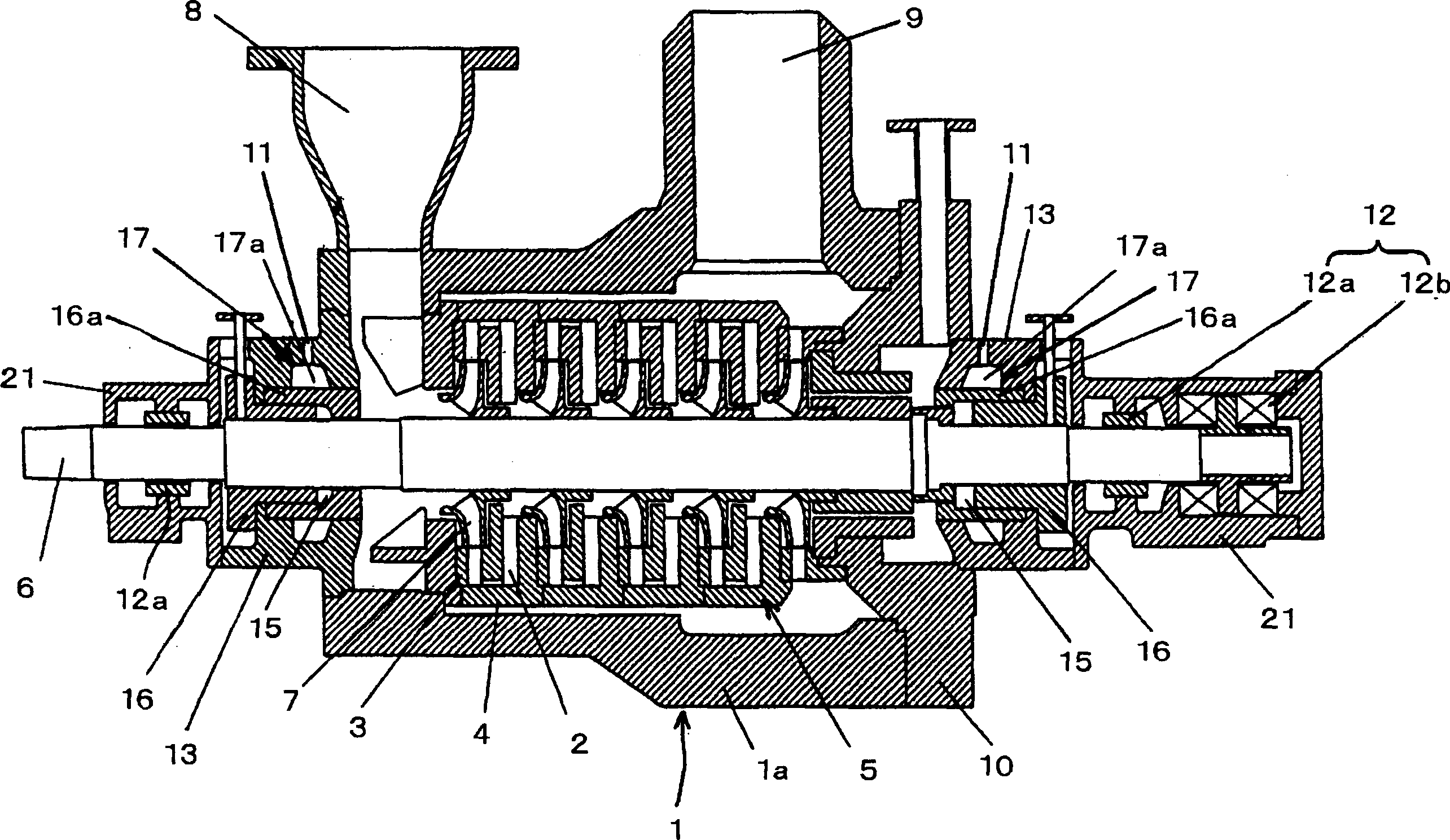

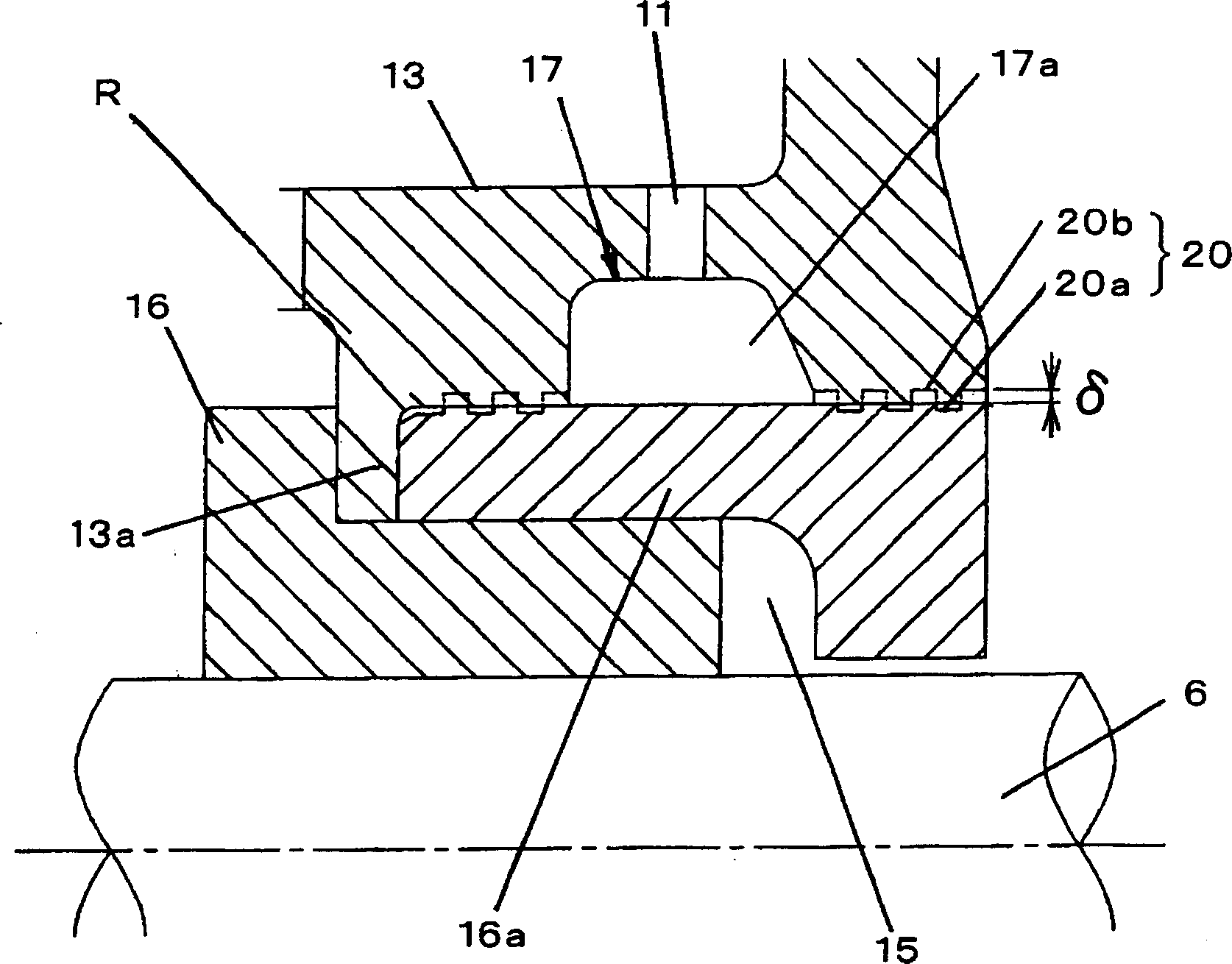

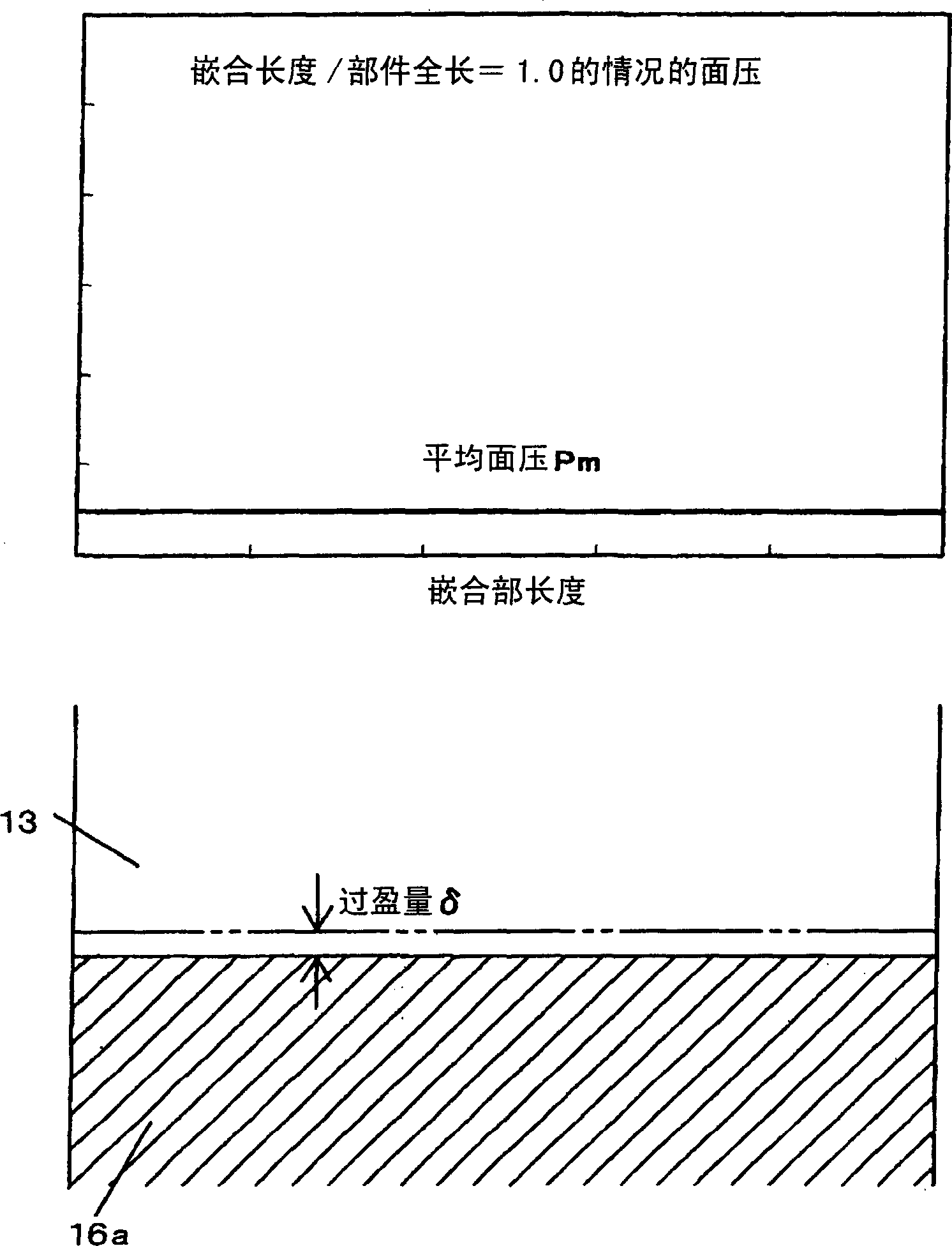

[0028] An embodiment of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional view of a cylindrical multistage turbo pump as an example of an industrial pump, figure 2 yes figure 1 A detailed longitudinal section in the vicinity of the shaft seal of the turbo pump shown. image 3 and Figure 4 It is a schematic diagram explaining the shrink fitting of the shaft seal case of an industrial pump.

[0029] exist figure 1 In the pump main body 1 of the turbo pump shown, an inner case 5 is provided in an outer case 1a called a cylinder case. Multi-stage pump stage (stage)4. The outer case 1a is coaxial with the center of the inner case 5, and the rotation shaft 6 which penetrates the center part of the inner case 5 is provided. An impeller 7 provided on each pump stage 4 is attached to the rotating shaft 6 .

[0030] An inflow port 8 is provided on one end side outer peripheral portion of the outer case 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com