Modularization vacuum switch

A vacuum switch, modular technology, applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problem of re-ignition of the disconnected capacitor bank, and achieve the solution of re-ignition, long electrical life, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

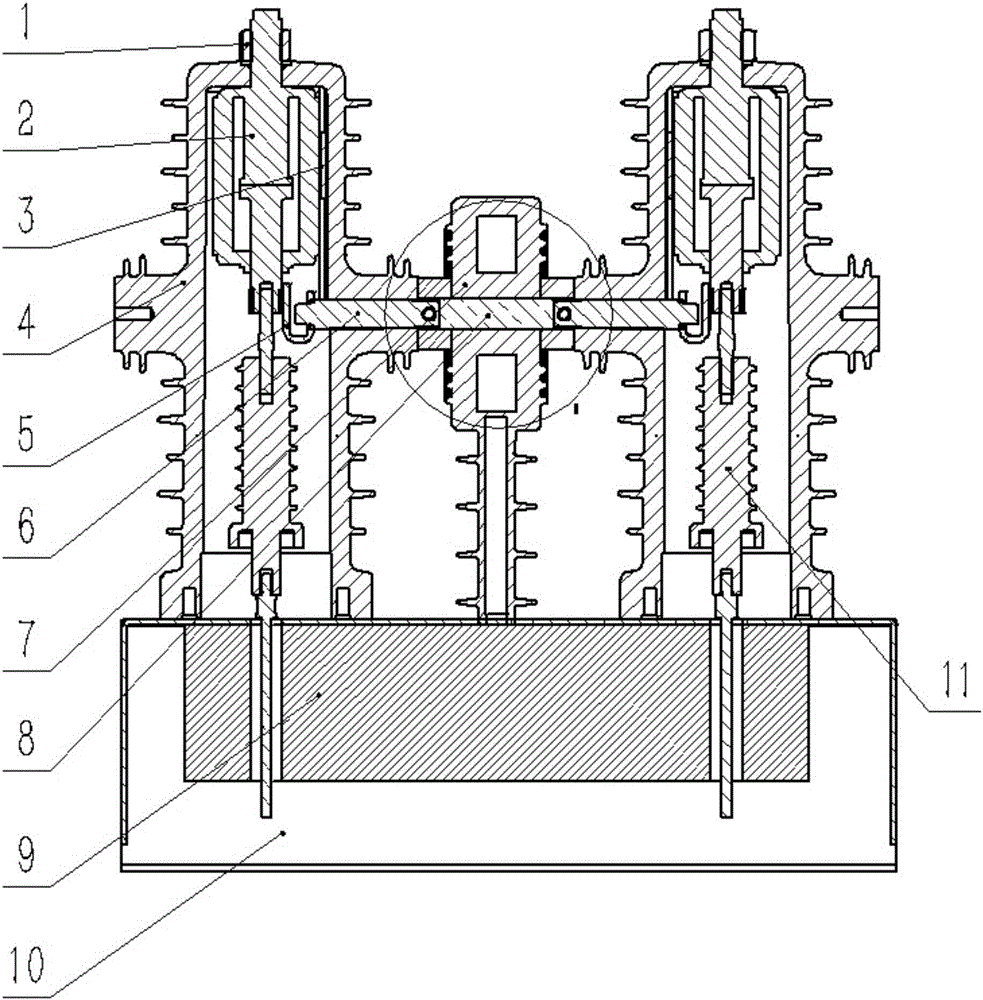

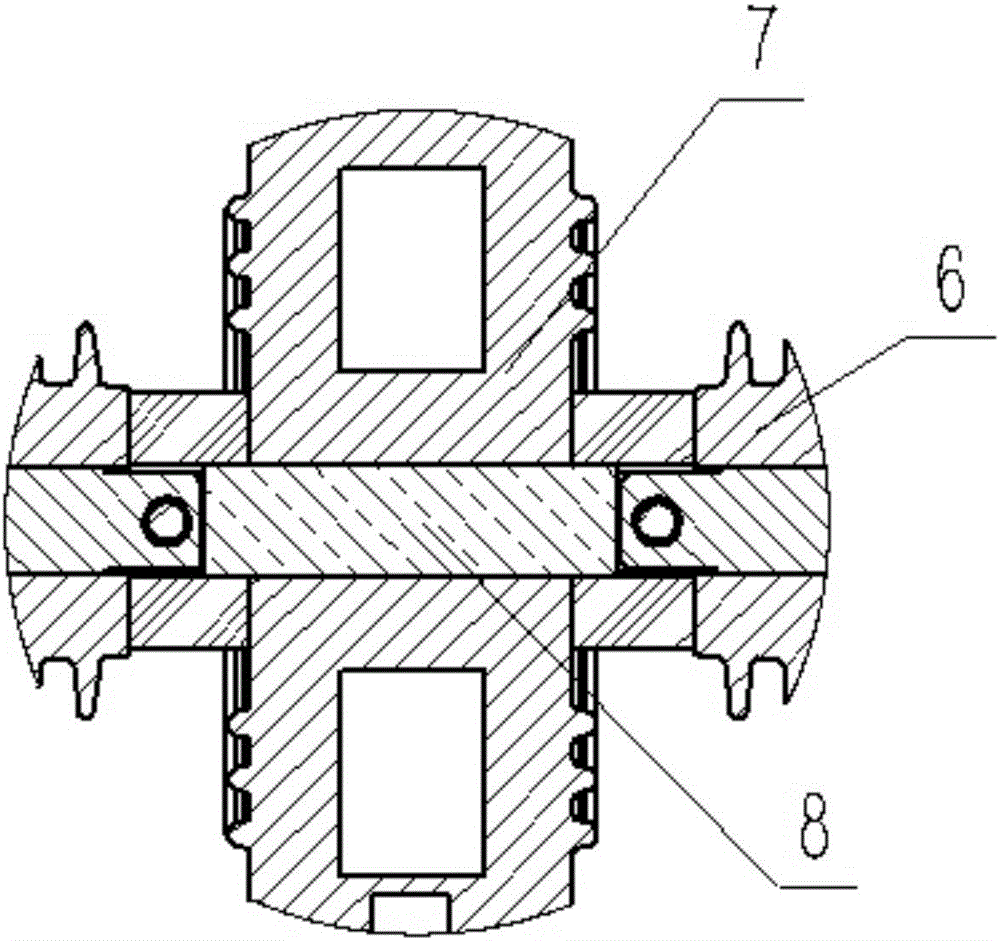

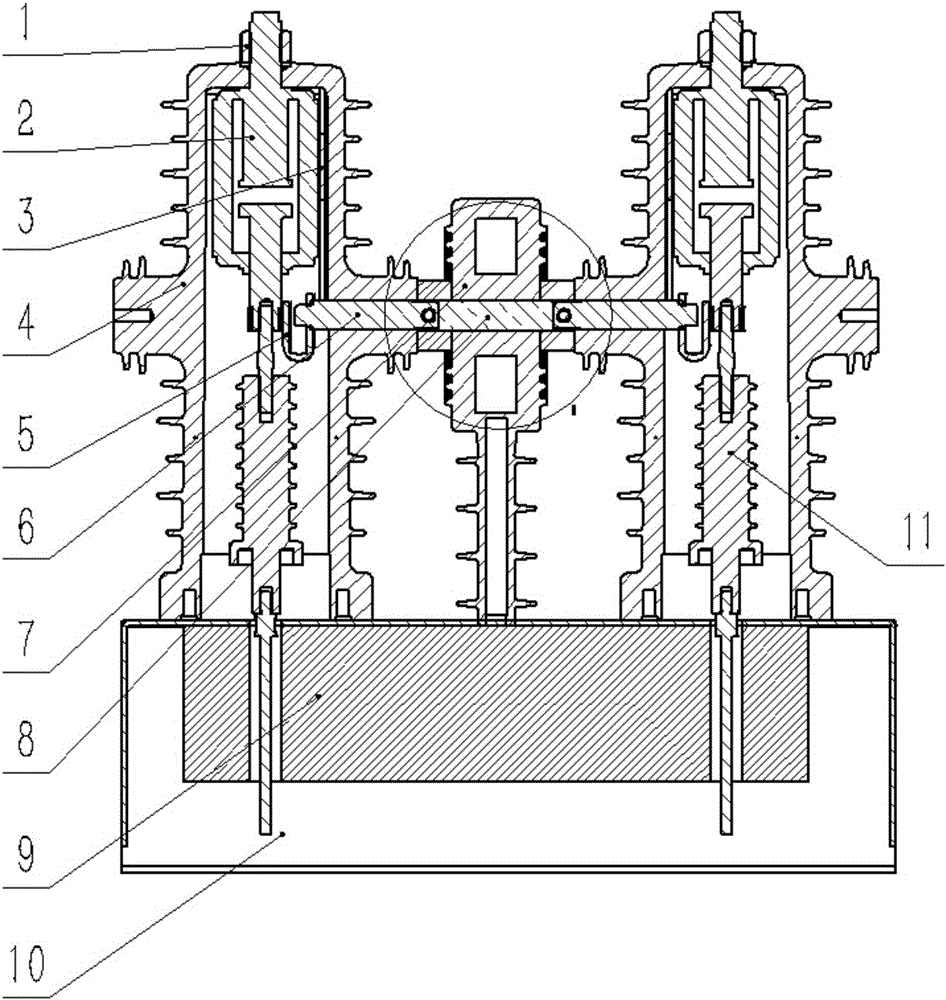

[0027] figure 1 is a sectional view of Embodiment 1 of the present invention, figure 2 It is a partially enlarged view of the current transformer module part of Embodiment 1 of the present invention, image 3 It is a schematic diagram of the disconnected state of Embodiment 1 of the present invention, Figure 4 It is a perspective view of a three-phase switch composed of a plurality of vacuum switches of Embodiment 1. In the figure, the meanings of each reference mark are as follows: 1. Top terminal; 2. Interrupter; 3. Voltage equalizing capacitor; 4. Insulating shell; 5. Flexible connection piece; Current transformer module; 8. Intermediate conductor; 9. Operating mechanism; 10. Switch base; 11. Insulation pull rod.

[0028] A modular vacuum switch, comprising two insulating shells 4, the outer of the insulating shell 4 is provided with sheds, the interior of the insulating shell 4 is provided with an arc extinguishing chamber 2, and the static end of the arc extinguishin...

Embodiment 2

[0038] Figure 5 It is a perspective view of a three-phase switch composed of a plurality of vacuum switches of Embodiment 2. In the figure, the reference signs that have appeared in the drawings used in Embodiment 1 still follow the definition of the reference signs in the above-mentioned embodiment.

[0039] The difference between this embodiment and Embodiment 1 is that the current transformer module provided on the intermediate conductor in Embodiment 1 is canceled in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com