Rolling bearing fault diagnosis method and system based on discrete cosine cyclic spectrum coherence

A discrete cosine and rolling bearing technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of data distribution differences, large amount of calculation in the processing process, and pollution of fault information, etc., to achieve enhanced accuracy and domain adaptability, reduced feature learning difficulty, and the effect of accurate and rapid diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

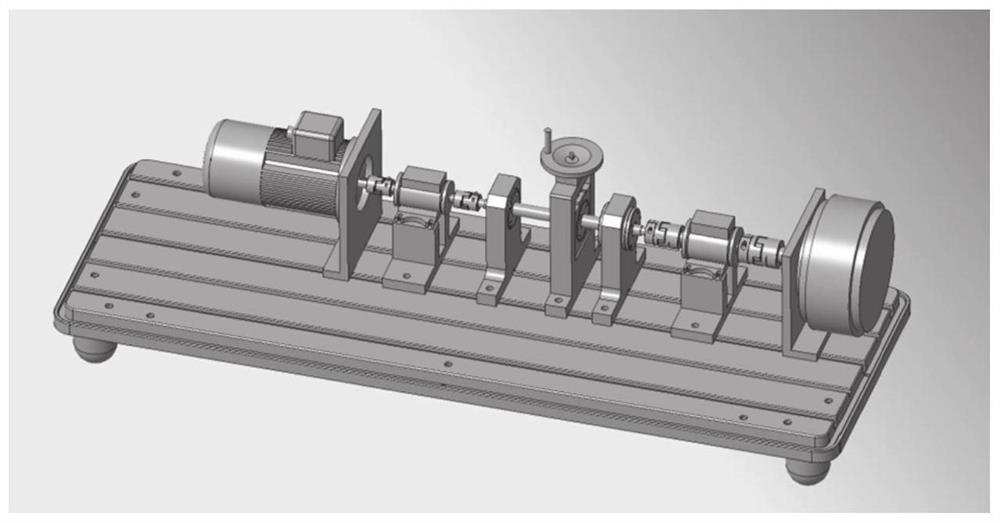

[0060] Embodiment 1 of the present invention provides a discrete cosine cyclic spectrum coherence feature (Discrete CosineTransformCyclic Spectral Coherence, DCTCSCoh), and based on this, a novel rolling bearing fault diagnosis method based on DCTCSCoh and CNN is proposed, such as figure 1 shown, including:

[0061] Obtain the time-domain vibration signal of the rolling bearing;

[0062] Extract the coherent features of the discrete cosine cyclic spectrum from the time-domain vibration signal, and obtain a two-dimensional discrete cosine cyclic spectrum coherent feature map;

[0063] According to the two-dimensional discrete cosine cyclic spectrum coherent feature map and the preset convolutional neural network model, the final diagnosis result is obtained.

[0064] Specifically, the extraction of the two-dimensional discrete cosine cyclic spectrum coherent feature map and the training of the preset convolutional neural network model include the following:

[0065] Step 1: C...

Embodiment 2

[0147] Embodiment 2 of the present invention provides a rolling bearing fault diagnosis system, including:

[0148] The data acquisition module is configured to: acquire the time-domain vibration signal of the rolling bearing;

[0149] The feature extraction module is configured to: extract discrete cosine cyclic spectrum coherent features for the time domain vibration signal, and obtain a two-dimensional discrete cosine cyclic spectrum coherent feature map;

[0150] The fault diagnosis module is configured to: obtain the final diagnosis result according to the two-dimensional discrete cosine cyclic spectrum coherent feature map and the preset convolutional neural network model.

[0151] The working method of the system is the same as the rolling bearing fault diagnosis method provided in Embodiment 1, and will not be repeated here.

Embodiment 3

[0153] Embodiment 3 of the present invention provides a computer-readable storage medium on which a program is stored. When the program is executed by a processor, the method for diagnosing rolling bearing faults based on discrete cosine cyclic spectrum coherence as described in Embodiment 1 of the present invention is implemented. A step of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com