Environment-friendly styrene butadiene polymer pervious concrete release agent and preparation method thereof

A technology of styrene butadiene and permeable concrete, which is used in lubricating compositions, manufacturing tools, ceramic molding machines, etc., can solve problems such as harsh process conditions, inability to fully meet the requirements of demoulding of permeable concrete, and unfavorable environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

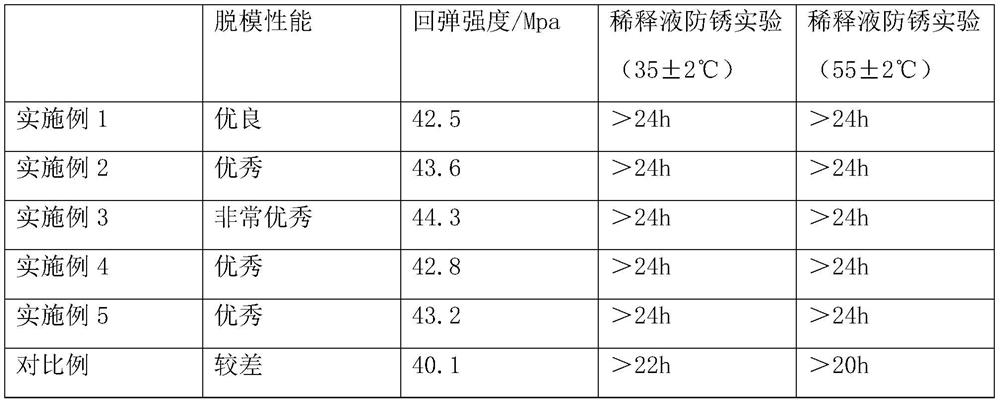

Examples

Embodiment 1

[0030] An environment-friendly styrene-butadiene polymer permeable concrete release agent, calculated in parts by weight, is made of the following raw materials:

[0031] 40 parts of water-soluble styrene butadiene polymer, 20 parts of calcium formate, 8 parts of 100# solvent oil, 20 parts of white oil, 25 parts of mineral oil, 25 parts of emulsified silicone oil, 40 parts of waste engine oil, 200 parts of glycerol, 1 part of petroleum ether, 10 parts of dodecyl diethanolamide, 1 part of lauryl stearate, 1 part of butyl stearate, 80 parts of deionized water, 0.5 parts of coalescent, 3 parts of rust inhibitor , 30 parts of activated powder.

[0032] The film-forming aid is an environment-friendly film-forming aid, the rust inhibitor is fatty acid, and the activation powder is sepiolite powder.

[0033] The preparation method of described release agent is made up of the following steps:

[0034] 1) Fully stir and mix the solvent oil, white oil, mineral oil, emulsified silicone...

Embodiment 2

[0038] An environment-friendly styrene-butadiene polymer permeable concrete release agent, calculated in parts by weight, is made of the following raw materials:

[0039]45 parts of water-soluble styrene butadiene polymer, 23 parts of calcium formate, 9 parts of 100# solvent oil, 23 parts of white oil, 30 parts of mineral oil, 35 parts of emulsified silicone oil, 60 parts of waste engine oil, 300 parts of glycerol, 2 parts of petroleum ether, 20 parts of lauryl diethanolamide, 2 parts of lauryl stearate, 1 part of butyl stearate, 100 parts of deionized water, 0.5 parts of coalescent, 5 parts of rust inhibitor , 40 parts of activated powder.

[0040] The film-forming aid is environment-friendly film-forming aid AH-12, the rust inhibitor is alcohol amine, and the activation powder is cross-linked polytetrafluoroethylene powder.

[0041] The preparation method of described release agent is made up of the following steps:

[0042] 1) Fully stir and mix the solvent oil, white oil...

Embodiment 3

[0046] An environment-friendly styrene-butadiene polymer permeable concrete release agent, calculated in parts by weight, is made of the following raw materials: 50 parts of water-soluble styrene-butadiene polymer, 25 parts of calcium formate, 12 parts of 200# solvent oil 25 parts of white oil, 33 parts of mineral oil, 40 parts of emulsified silicone oil, 70 parts of waste engine oil, 350 parts of glycerol, 3 parts of petroleum ether, 22 parts of lauryl diethanolamide, 3 parts of lauryl stearate 1.5 parts, 1.5 parts of butyl stearate, 115 parts of deionized water, 1.25 parts of film-forming aid, 6.5 parts of rust inhibitor, and 45 parts of activated powder.

[0047] The film-forming aid is an environment-friendly film-forming aid AH-12, the rust inhibitor is sodium benzoate, and the activation powder is composed of sepiolite powder:cross-linked polytetrafluoroethylene powder=1:2 in mass ratio.

[0048] The preparation method of described release agent is made up of the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com