Preparation method of full-flexible printable patterned electrode

A patterned electrode and graphic printing technology, which is applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, circuits, etc., can solve the problems of incomplete transfer and poor conductive uniformity of conductive films, etc., to improve the conductivity Effects of uniformity, resolution enhancement, and dispersion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

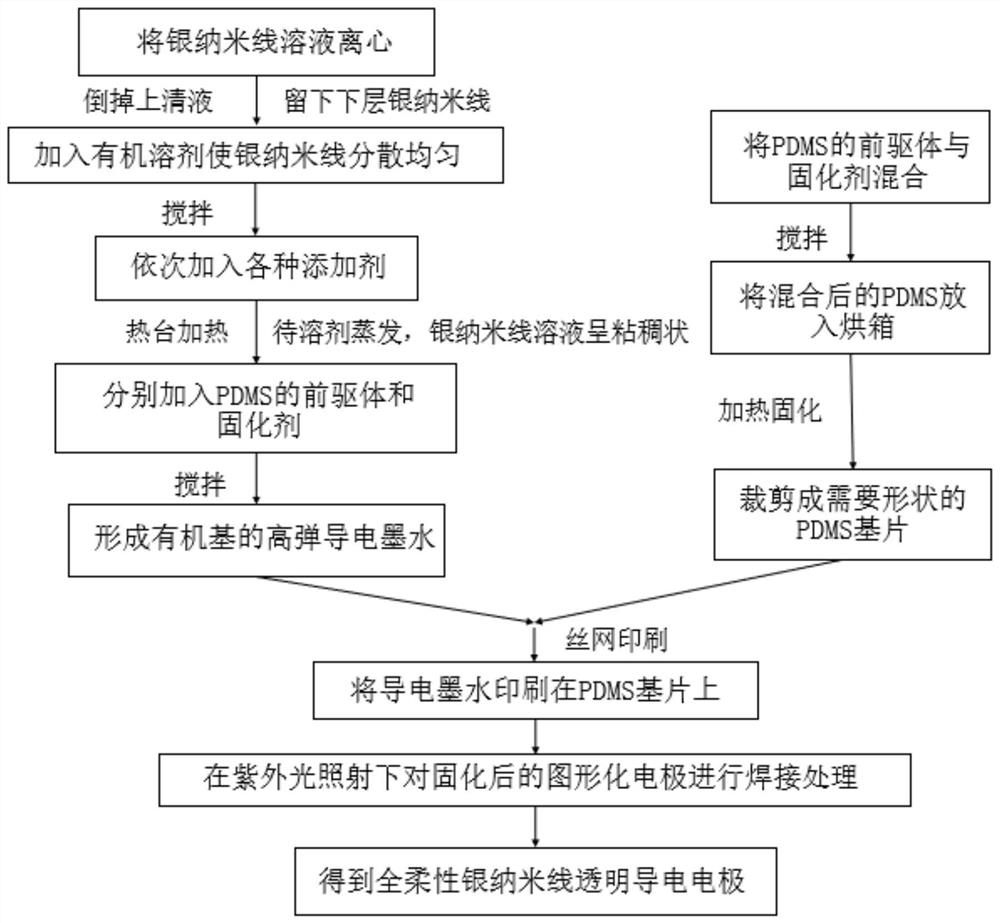

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The thickener adopts 0.1% by mass of sodium alginate, the surfactant adopts 0.01% by mass of fluorocarbon surfactant FS-3100, and the leveling agent adopts 0.001% by mass of polyether Modified organopolysiloxane MY-300, the dispersant uses ethanolamine ETA with a mass percentage of 0.01%, the ultraviolet finishing agent uses 0.01% by mass of benzoin bismethyl ether pyridine, and the defoamer adopts 0.01% by mass of ethanol fully flexible printable patterned electrodes.

[0030] Step 1: Make polydimethylsiloxane PDMS substrate.

[0031] 1.1) Mix 10g of polydimethylsiloxane PDMS precursor with 1g of curing agent and stir thoroughly, then place it in a centrifuge and rotate at 7000r / min for 3min to remove the bubbles that appear during the stirring process;

[0032] 1.2) Pour the mixed PDMS into a square container to form a 0.5mm thick PDMS film, let it stand for 0.2h in the air environment to make it level naturally, then put it into an oven to heat it, at ...

Embodiment 2

[0041] Example 2: The thickener uses 1% by mass of carboxymethylcellulose sodium CMC, the surfactant uses 0.5% by mass of TF380, and the leveling agent uses 0.1% by mass of Shanggao sago-3223 , the dispersant adopts sago9760 with a mass percentage of 0.5%, the ultraviolet finishing agent adopts 0.1% diphenyl ethyl ketone and 0.1% 1-hydroxycyclohexyl phenyl ketone, and the defoamer adopts a mass percentage of Fully flexible printable patterned electrodes with 0.1% mineral oil defoamer MO-2170.

[0042] Step 1: Make a polydimethylsiloxane PDMS substrate.

[0043] First, mix 10g of polydimethylsiloxane PDMS precursor with 1g of curing agent and stir thoroughly, and then put it into a centrifuge for centrifugation to remove the bubbles that appear during the stirring process. The speed of the centrifuge is 6000r / min , the rotation time is 4.5min;

[0044] Secondly, pour the mixed PDMS into the container to form a 0.5mm thick PDMS film, let it stand for 0.2h in the air environment ...

Embodiment 3

[0053] Embodiment 3: The hydroxypropyl methylcellulose HPMC of 2.4% by mass is used to make the thickener, the TF380 of 0.1% by mass is used as the surfactant, and the high sago- 3223, the dispersant uses 0.1% by mass percentage of Shanggao sago9760, the ultraviolet finishing agent uses 0.01% by mass percentage of 2-(2′-hydroxy-5′-methylphenyl)benzotriazole, 0.01% of 4- Benzoyloxy-2,6,2,6-tetramethylpiperidine and defoaming agent are fully flexible printable patterned electrodes using 1% by mass ethanol.

[0054] Step A: Fabricate a polydimethylsiloxane PDMS substrate.

[0055] A1) After mixing 10g of polydimethylsiloxane PDMS precursor with 1g of curing agent and fully stirring, spin in a centrifuge at a speed of 7000r / min for 4min to remove the bubbles that appear during the stirring process;

[0056] A2) Pour the mixed PDMS into a square container to form a 0.5mm thick PDMS film, let it stand for 0.2h in the air environment to make it level naturally, and then put it into ...

PUM

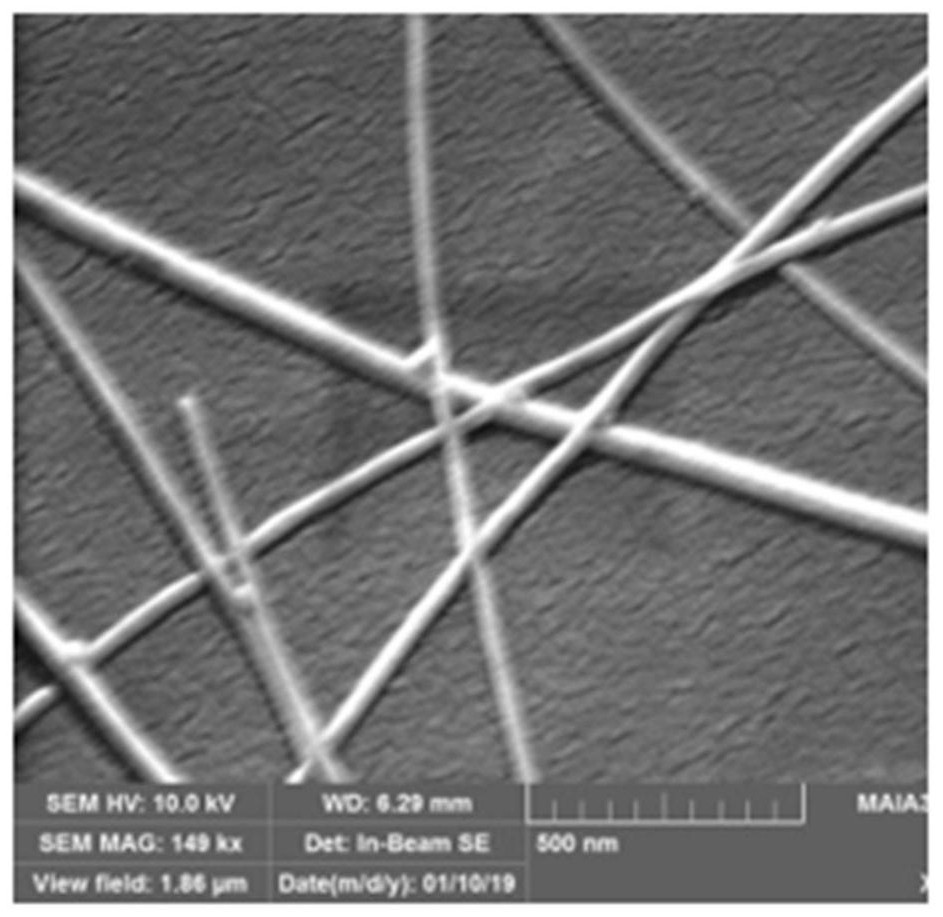

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com