Preparation method of spirocyclic phosphate flame retardant for spandex fiber and flame-retardant spandex fiber based on spirocyclic phosphate flame retardant

A spirocyclic phosphoric acid and spandex fiber technology, applied in the field of flame-retardant textile fibers, can solve the problems of difficulty in fully releasing flame-retardant efficiency, poor air and moisture permeability of textiles, poor compatibility and spinnability, and achieve good spinnability, Excellent washing resistance, flame retardant and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

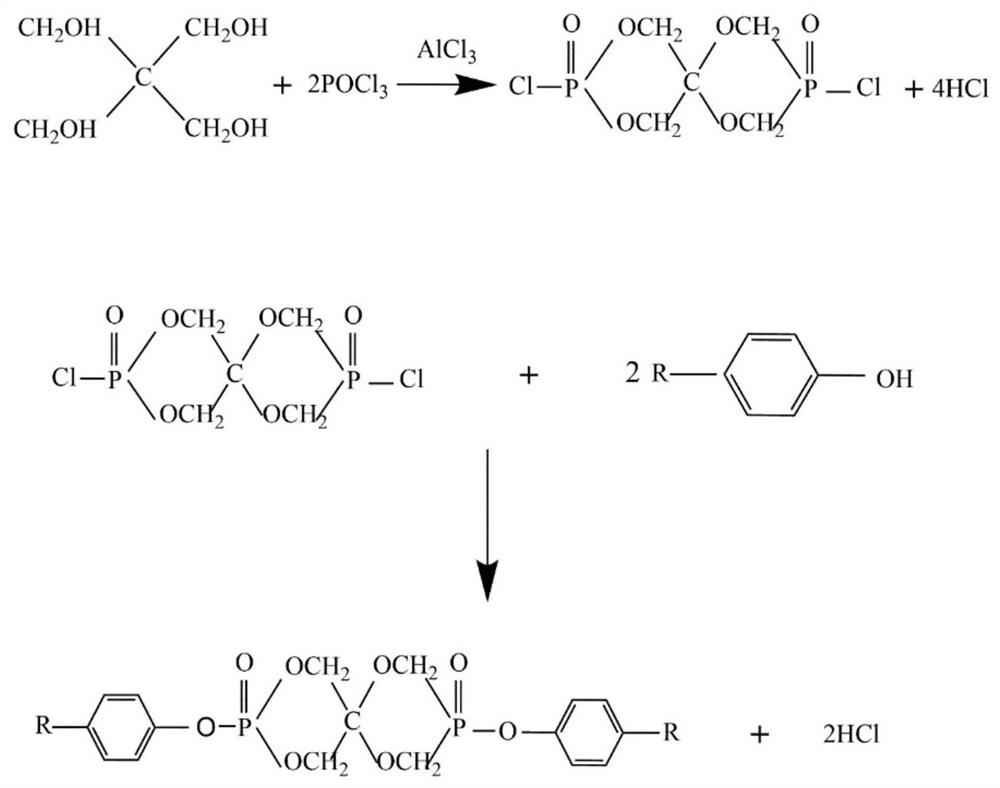

[0023] A stirrer, a thermometer and a condenser are installed in a dry reactor. Stir 54.1g of benzoquinone and 27.2g of pentaerythritol evenly, add 2.1g of anhydrous aluminum chloride, heat to 90°C, then slowly add 68.7g of phosphorus oxychloride, react at 90°C for 5 hours, cool to room temperature after the reaction is completed , using sodium hydroxide with a mass concentration of 10% to adjust the pH of the flame retardant to 7, and distilling under reduced pressure at 150° C. for 8 hours to obtain a transparent viscous liquid, which is a spirocyclic phosphate flame retardant. The whole reaction process is carried out under the condition of stirring (speed 400r / min).

Embodiment 2

[0025] A stirrer, a thermometer and a condenser are installed in a dry reactor. Stir 47.1g of phenol and 27.2g of pentaerythritol evenly, add 1.5g of anhydrous aluminum chloride, heat to 90°C, then slowly add 83.7g of phosphorus oxychloride, react at 90°C for 5 hours, cool to room temperature after the reaction is completed, Using sodium hydroxide with a mass concentration of 10% to adjust the pH of the flame retardant to 7, distilling under reduced pressure at 150° C. for 8 hours to obtain a transparent viscous liquid, which is a spirocyclic phosphate flame retardant. The whole reaction process is carried out under the condition of stirring (speed 300r / min).

Embodiment 3

[0027] A stirrer, a thermometer and a condenser are installed in a dry reactor. Stir 55.2g of hydroquinone and 27.2g of pentaerythritol evenly, add 1.8g of anhydrous aluminum chloride, heat to 90°C, then slowly add 93.2g of phosphorus oxychloride, react at 90°C for 5 hours, after the reaction is completed Cool down to room temperature, use 10% sodium hydroxide to adjust the pH of the flame retardant to 7, and distill under reduced pressure at 150°C for 8 hours to obtain a transparent viscous liquid, which is a spirocyclic phosphate flame retardant. Whole reaction process all carries out under the condition of stirring (speed 500r / min).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com