High-yield-strength cast aluminum alloy and preparation method thereof

A casting aluminum alloy, high-yield technology, applied in the field of aluminum alloys, can solve problems such as surface bubbles, difficult to meet yield strength and fracture strength, cracks, etc., to improve tensile strength and yield strength, optimize preparation methods, and avoid safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

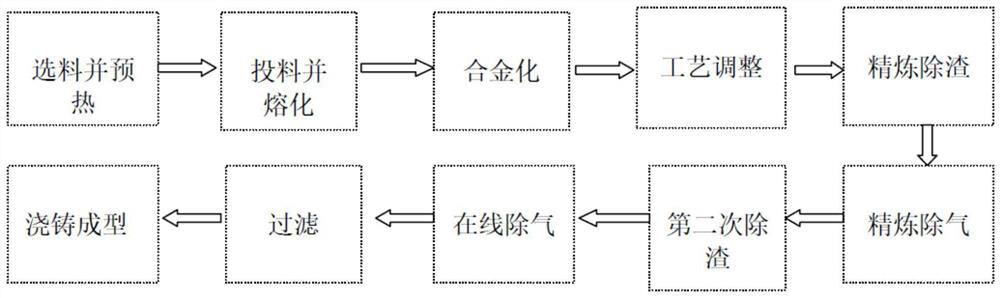

Image

Examples

Embodiment 1

[0050] Embodiment one high yield strength casting aluminum alloy

[0051] High yield strength cast aluminum alloy, made of the following components in mass percentage: Si 6.5%, Fe 0.65%, Mg 0.68%, Zn 12.8%, Mn 0.25%, Cu 4.0%, Cr 0.10%, Sr 0.08% , Ti 0.09%, Ni0.08%, B<0.001%, impurity metal element<0.08%, and the balance is Al. B is introduced by adding aluminum strontium titanium boron alloy; impurity metal elements include: Pb, Cd, Ca, Na, Sb, Pb<0.03%, Ca<0.01%, Na<0.01%, Sb<0.01%, Cd<0.02% .

[0052] A method for preparing cast aluminum alloys with high yield strength, comprising the following steps:

[0053] 1) Select raw materials and preheat: select the following raw materials according to the formula: aluminum ingots for remelting, industrial silicon, electrolytic copper, zinc ingots, electrolytic nickel, magnesium ingots, electrolytic manganese, aluminum-iron master alloys, aluminum-chromium master alloys, aluminum-titanium Master alloy, aluminum strontium titanium ...

Embodiment 2

[0063] Example 2 High Yield Strength Cast Aluminum Alloy

[0064] High yield strength cast aluminum alloy, made of the following components in mass percentage: Si 6.8%, Fe 0.70%, Mg 0.65%, Zn 12.5%, Mn 0.30%, Cu 3.8%, Cr 0.12%, Sr 0.08% , Ti 0.08%, Ni0.09%, B<0.001%, impurity metal element<0.08%, and the balance is Al. B is introduced by adding aluminum strontium titanium boron alloy; impurity metal elements include: Pb, Cd, Ca, Na, Sb, Pb<0.03%, Ca<0.01%, Na<0.01%, Sb<0.01%, Cd<0.02% .

[0065] A method for preparing cast aluminum alloys with high yield strength, comprising the following steps:

[0066] 1) Select raw materials and preheat: select the following raw materials according to the formula: aluminum ingots for remelting, industrial silicon, electrolytic copper, zinc ingots, electrolytic nickel, magnesium ingots, electrolytic manganese, aluminum-iron master alloys, aluminum-chromium master alloys, aluminum-titanium Master alloy, aluminum strontium titanium boron al...

Embodiment 3

[0076] Example 3 High Yield Strength Cast Aluminum Alloy

[0077] High yield strength cast aluminum alloy, made of the following components in mass percentage: Si 6.3%, Fe 0.68%, Mg 0.60%, Zn 12.2%, Mn 0.35%, Cu 3.6%, Cr 0.09%, Ti 0.10% , Sr 0.10%, Ni0.06%, B<0.001%, impurity metal element<0.08%, and the balance is Al. B is introduced by adding aluminum strontium titanium boron alloy; impurity metal elements include: Pb, Cd, Ca, Na, Sb, Pb<0.03%, Ca<0.01%, Na<0.01%, Sb<0.01%, Cd<0.02% .

[0078] A method for preparing cast aluminum alloys with high yield strength, comprising the following steps:

[0079] 1) Select raw materials and preheat: select the following raw materials according to the formula: aluminum ingots for remelting, industrial silicon, electrolytic copper, zinc ingots, electrolytic nickel, magnesium ingots, electrolytic manganese, aluminum-iron master alloys, aluminum-chromium master alloys, aluminum-titanium Master alloy, aluminum strontium titanium boron al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com