Novel high-conductivity copper alloy wire and application thereof

A high-conductivity, copper alloy technology, applied in the field of copper alloy wire, can solve the problems of limited applicability and insufficient mechanical strength, and achieve the effects of strong anti-interference, excellent mechanical properties, and large elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment relates to a method for preparing a novel high-conductivity copper alloy wire, which generally follows the steps below:

[0053] Step 1: batching according to the above weight percentage, followed by melting in the following stages:

[0054] Ⅰ: Heat and melt the copper block in a smelting furnace with a temperature of 1120°C, and keep it warm for 50 minutes;

[0055] Ⅱ: Add ferrosilicon powder, scandium powder and erbium powder into the smelting furnace, and heat it to 1560°C at a heating rate of 30°C / min under stirring conditions to fully melt the powder, and keep it warm for 70 minutes;

[0056] Ⅲ: The temperature of the copper liquid obtained in the control stage Ⅱ is 1150°C, and then flows through the graphite rotor with a rotation speed of 160r / min set on the launder, the degassing box with an argon pressure of 210KPa, and the ceramic with a porosity of 60ppi The filter plate is degassed and filtered on-line, and finally transferred to a vacuum hol...

Embodiment 2

[0065] This embodiment relates to a method for preparing a novel high-conductivity copper alloy wire, which generally follows the steps below:

[0066] Step 1: batching according to the above weight percentage, followed by melting in the following stages:

[0067] Ⅰ: Heat and melt the copper block in a melting furnace with a temperature of 1125°C, and keep it warm for 48 minutes;

[0068] Ⅱ: Add ferrosilicon powder, scandium powder and erbium powder into the smelting furnace, and heat it to 1565°C at a heating rate of 32°C / min under stirring conditions to fully melt the powder, and keep it warm for 68 minutes;

[0069] Ⅲ: The temperature of the copper liquid obtained in the control stage Ⅱ is 1155°C, and then flows through the graphite rotor with a rotation speed of 165r / min set on the launder, the degassing box with an argon pressure of 215KPa, and the ceramic with a porosity of 65ppi The filter plate is degassed and filtered online, and finally transferred to the vacuum hol...

Embodiment 3

[0078] This embodiment relates to a method for preparing a novel high-conductivity copper alloy wire, which generally follows the steps below:

[0079] Step 1: batching according to the above weight percentage, followed by melting in the following stages:

[0080] Ⅰ: Heat and melt the copper block in a smelting furnace with a temperature of 1130°C, and keep it warm for 45 minutes;

[0081] Ⅱ: Add ferrosilicon powder, scandium powder and erbium powder into the smelting furnace, and under stirring conditions, heat to 1570°C at a heating rate of 35°C / min to fully melt the powder, and keep it warm for 65 minutes;

[0082] Ⅲ: The temperature of the copper liquid obtained in the control stage Ⅱ is 1160°C, and then flows through the graphite rotor with a rotation speed of 170r / min set on the launder, the degassing box with an argon pressure of 220KPa, and the ceramic with a porosity of 70ppi The filter plate is degassed and filtered online, and finally transferred to the vacuum hold...

PUM

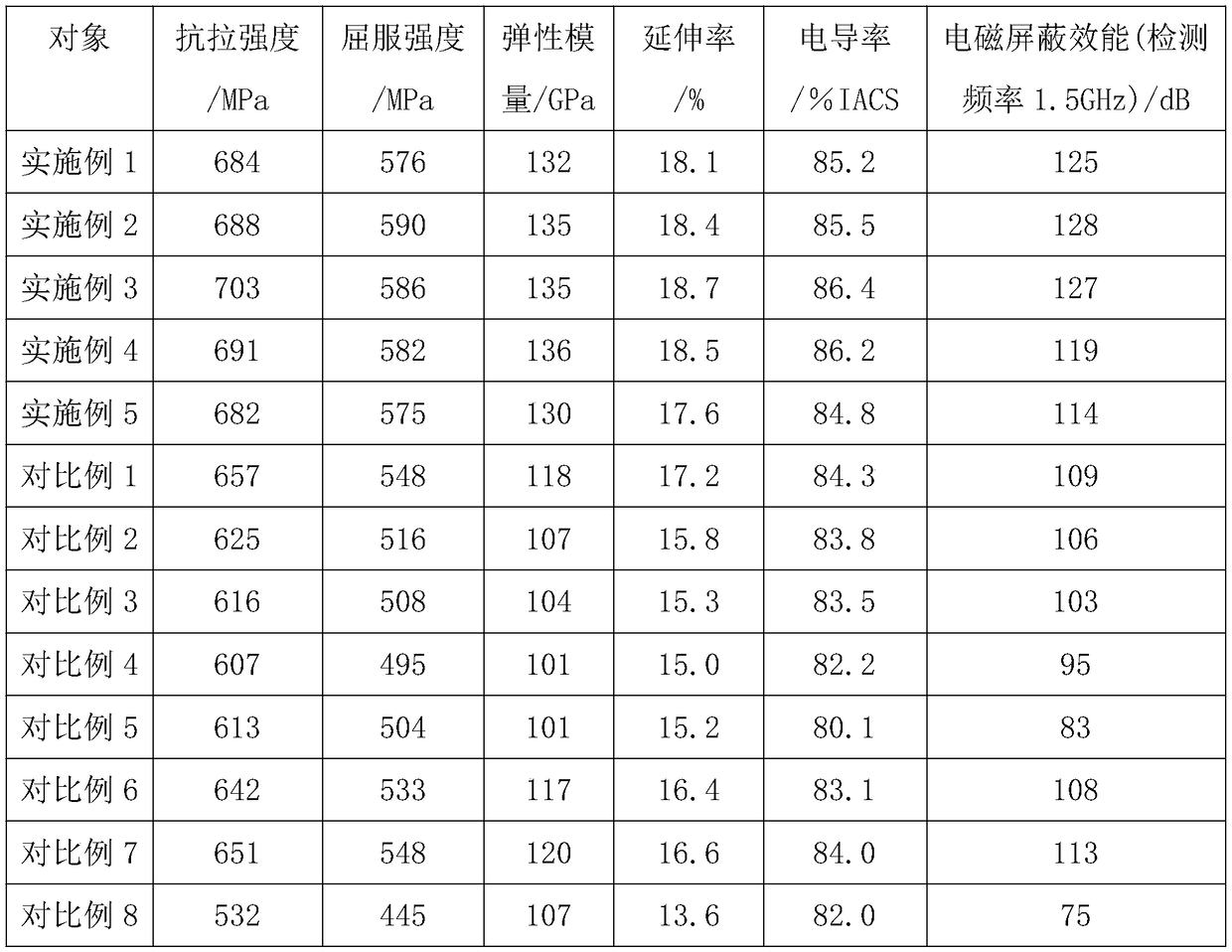

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com