Silicon dioxide aerogel reinforced copper-based composite material and preparation method thereof

A technology of copper-based composite materials and silicon dioxide, applied in the field of particle-reinforced metal-based composite materials, metal materials and their preparation, to achieve the effects of improved mechanical properties, low cost, and excellent electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

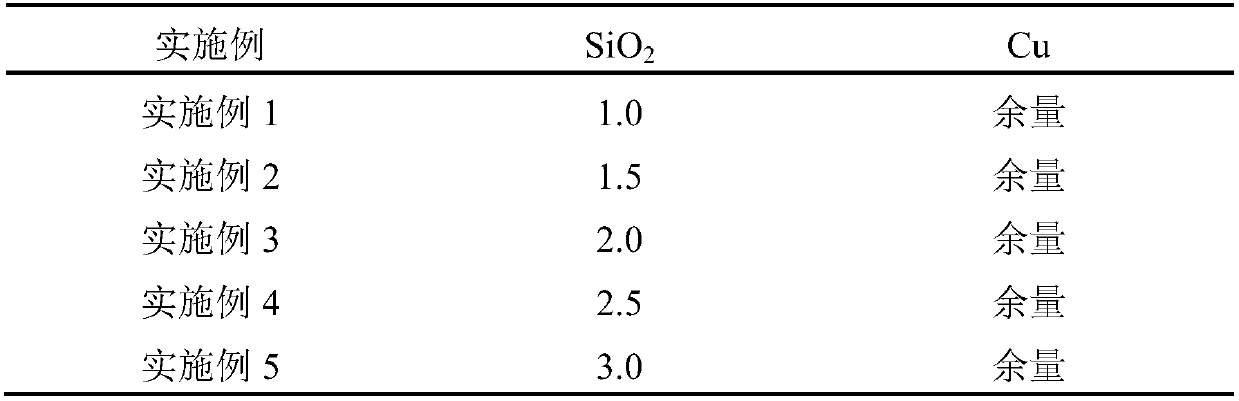

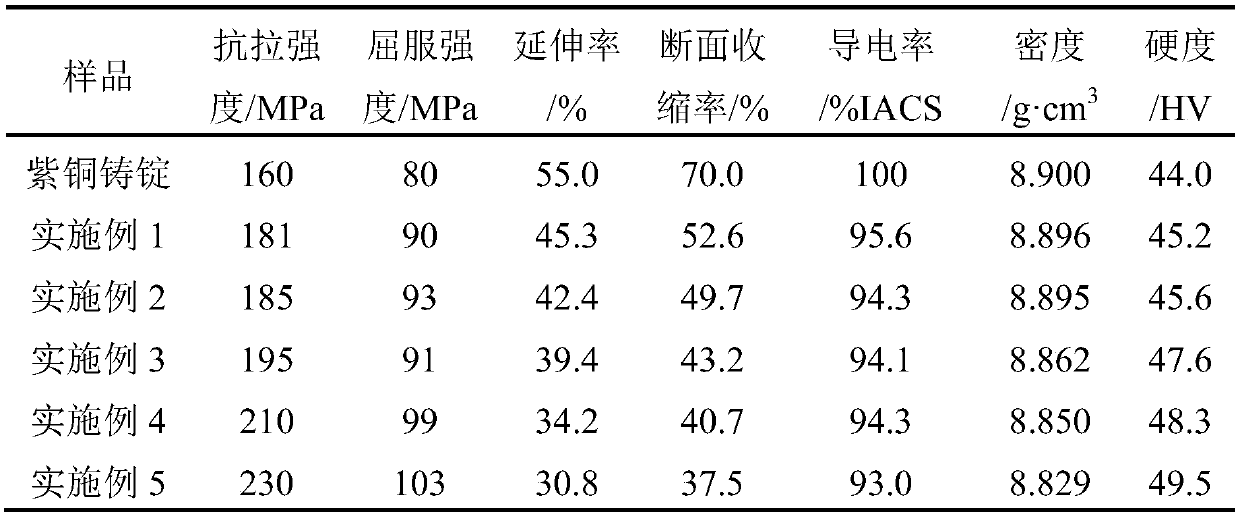

[0036] Preparation of Cu-1wt.%SiO 2 Airgel composite material, its production process method is: (1) Cu-SiO 2 Preparation of airgel master alloy: batching-mixing-cold pressing; (2) preparation of composite materials: vacuum melting-casting.

[0037] The specific process is: according to Table 1 ingredient distribution. First, prepare Cu-10wt.%SiO 2 Airgel master alloy, mix electrolytic copper powder and silica airgel in a double-cone high-efficiency mixer for 12 hours, and then press the mixed powder under a hydraulic press with a pressure of 15MPa to form a block. Finally, T2 pure copper and Cu-10wt.% SiO prepared according to the target composition 2 The master alloy is placed in a vacuum medium frequency induction furnace and melted at 1200°C. After the pure copper is melted, the temperature is lowered to 1150°C before pouring. The properties of the prepared finished products are shown in Table 1.

Embodiment 2

[0039] Preparation of Cu-1.5wt.%SiO 2 Airgel composite material, its production process method is: (1) Cu-SiO 2 Preparation of airgel master alloy: batching-mixing-cold pressing; (2) preparation of composite materials: vacuum melting-casting.

[0040] The specific process is: according to Table 1 ingredient distribution. First, prepare Cu-10wt.%SiO 2 Airgel master alloy, mix electrolytic copper powder and silica airgel in a double-cone high-efficiency mixer for 12 hours, and then press the mixed powder under a hydraulic press with a pressure of 15MPa to form a block. Finally, T2 pure copper and Cu-10wt.% SiO prepared according to the target composition 2 The master alloy is placed in a vacuum medium frequency induction furnace and melted at 1250°C. After the pure copper is melted, the temperature is lowered to 1150°C before pouring. The properties of the prepared finished products are shown in Table 1.

Embodiment 3

[0042] Preparation of Cu-2wt.%SiO 2 Airgel composite material, its production process method is: (1) Cu-SiO 2Preparation of airgel master alloy: batching-mixing-cold pressing; (2) preparation of composite materials: vacuum melting-casting.

[0043] The specific process is: according to Table 1 ingredient distribution. First, prepare Cu-10wt.%SiO 2 Airgel master alloy, mix electrolytic copper powder and silica airgel in a double-cone high-efficiency mixer for 12 hours, and then press the mixed powder under a hydraulic press with a pressure of 15MPa to form a block. Finally, T2 pure copper and Cu-10wt.% SiO prepared according to the target composition 2 The master alloy is placed in a vacuum medium frequency induction furnace and melted at 1250°C. After the pure copper is melted, the temperature is lowered to 1150°C before pouring. The properties of the prepared finished products are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com