A kind of high-strength ultra-fine-grained magnesium-tin-bismuth-manganese alloy and its preparation method

A technology of crystalline magnesium-tin-bismuth-manganese alloy and magnesium-tin-bismuth-manganese alloy, which is applied in the field of high-strength ultra-fine-grained magnesium-tin-bismuth-manganese alloy and its preparation, can solve the problems of low absolute strength, poor low-temperature deformability, and high production cost of magnesium alloys. problem, to achieve the effect of promoting dynamic recrystallization, low cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023]实施例1

[0024]一种高强度超细晶镁锡铋锰合金,其组成及其重量百分比含量为Sn:5%;Bi:5%;Mn:0.5%,其余为镁以及无法避免的杂质。Mg2Sn、Mg3Bi2弥散相分布在合金基体上,具有小于1μm的超细晶组织。

[0025]一种高强度超细晶镁锡铋锰合金的制备方法,包括以下步骤:

[0026]1)原料准备:镁块、锡颗粒、铋颗粒、镁-锰中间合金块按照重量百分比含量配料,原料的纯度均为99.99%;

[0027]在本实施例1中,按下表1中各个化学物质材料质量准备好,并用砂轮将镁块和镁-锰中间合金块打磨光亮,然后放入干燥箱里进行干燥。同时将坩埚、坩埚钳、搅拌棒的表面均匀刷涂料,涂料的配方如下表2所示。

[0028]表1化学物质材料质量、形状、纯度

[0029]化学物质材料质量(g)形状纯度(%)Mg420固体块状99.99Sn26.25固体颗粒状99.99Bi26.25固体颗粒状99.99Mg-10%Mn52.5固体块状99.99

[0030]表2涂料配方

[0031]滑石粉(g)水(ml)水玻璃(g)8025020

[0032]2)熔炼成锭:将步骤1)准备的原料加入熔炼炉中,在SF6与CO2的混合保护气气氛中熔炼,然后浇铸成圆柱型铸锭;其中,SF6与CO2的体积比为40:1;

[0033]在本实施例中,具体的熔炼过程采用以下步骤:

[0034]a、首先,将坩埚预热至300℃左右,随即把已打磨、称好质量并且干燥后的镁块放在坩埚里,并将镁块与坩埚一起放入电阻炉,向电阻炉通入SF6与CO2的混合保护气,SF6与CO2的体积比为40:1;然后,待电阻炉升温至710℃,保温25min,将已干燥的Sn、Bi颗粒放入坩埚中;最后,将电阻炉升温至720℃,保温20min,随后已干燥的镁-锰中间合金再放入坩埚中;

[0035]b、将电阻炉升温至750℃,保温20min,使得Sn、Bi、Mn三种合金元素有足够长的时间在熔融的镁合金液中得到充分扩散,使合金成分均匀化;待保温结束后,为了准备精炼处理,再将电阻炉降温至740℃,精炼时需要对合金液剧烈搅拌,同时缓慢加精炼剂(精炼剂成分如下表3所示),整个精炼过程维持1-2min;

[0036]c、因精炼后导致电阻炉炉温降低,所以需要把电阻炉重新升温至740℃,保温20min,保温结束后等待炉温降至710℃,随后开始往已预热金属模具中开始浇铸(模...

Example Embodiment

[0048]实施例2

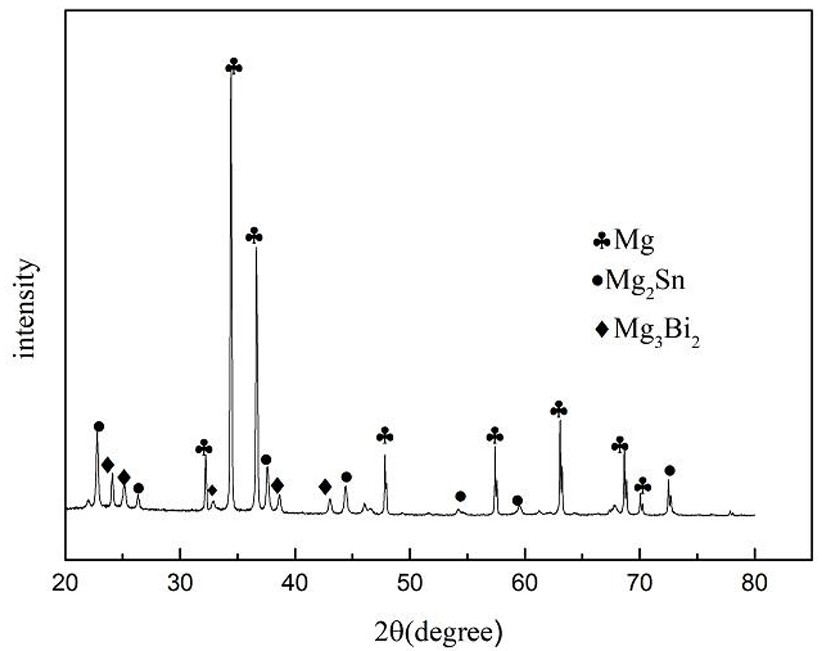

[0049]一种高强度超细晶镁锡铋锰合金,其组成及其重量百分比含量为Sn:5%;Bi:5%;Mn:1%,其余为镁以及无法避免的杂质。反应产物中各元素含量如图1中的XRD图谱所示,图1中纵坐标为衍射强度,横坐标为衍射角2θ,镁锡铋锰合金主要由ɑ-Mg相、Mg2Sn相、Mg3Bi2相组成。

[0050]一种高强度超细晶镁锡铋锰合金的制备方法,其步骤与实施例1相同,区别仅在于原料中元素含量不同,即镁锡铋锰合金组成及其重量百分比含量为Sn:5%;Bi:5%;Mn:1%,其余为镁以及无法避免的杂质。

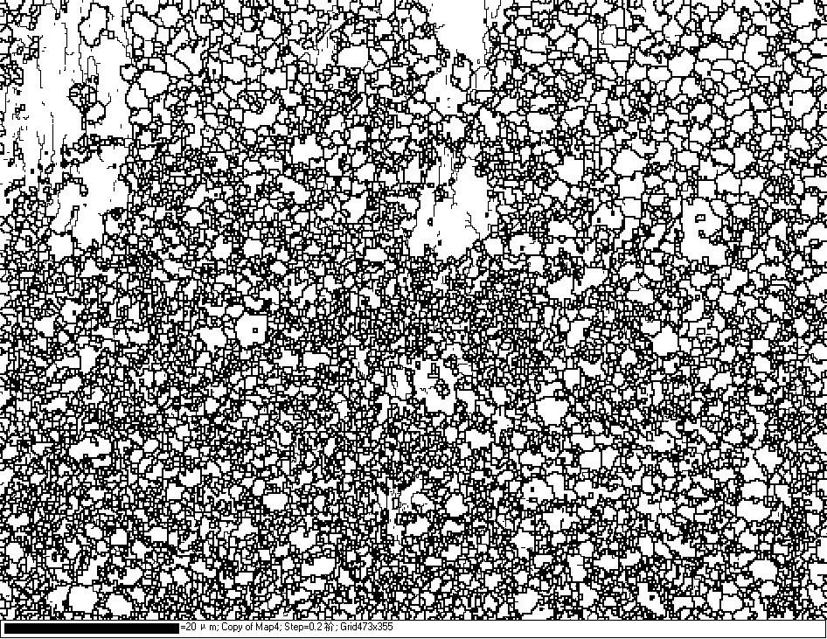

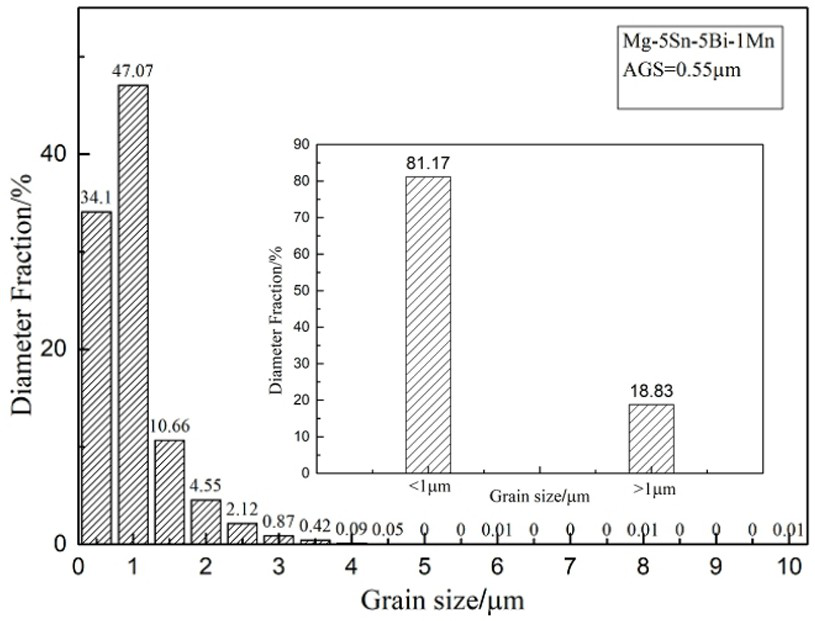

[0051]如图2所示,能观察到本实施例2制得的镁锡铋锰合金中存在大量细小的动态再结晶晶粒,以及少量长条状的未动态再结晶。如图3所示,本实施例2制得的镁锡铋锰合金在细小的动态再结晶中,晶粒尺寸小于1μm的晶粒占81.17%,平均晶粒尺寸(AGS)为0.55μm。如图4所示,延伸率2.4%左右,抗拉强度为414MPa,屈服强度为390MPa。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com