Preparation method of asphalt polyurethane waterproof coating suitable for cement base layer

A polyurethane waterproof and polyurethane prepolymer technology, applied in polyurea/polyurethane coatings, asphalt coatings, coatings, etc., can solve the problems of unfavorable safety production, unfavorable on-site construction, high viscosity, etc., and achieve fast surface drying and solid drying time , Conducive to on-site construction, to avoid the effect of violent reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 30 parts of end-blocked polyurethane prepolymers, 60 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing Agent silane 171 1 part, dibutyltin dilaurate 0.1 part, fumed silica 0.5 part, vinyltriethoxysilane 0.2 part, calcium oxide 0.1 part.

[0042] The preparation method comprises the following steps:

[0043] (1) Preparation of end-capped polyurethane prepolymer:

[0044] 50 parts of Dongda polyether diol 2000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 10 parts of BASF TDI and reacted at 80°C for 3 hours. The measured NCO content was about Terminate reaction when 4.6%, make 60 parts of polyurethane prepolymers;

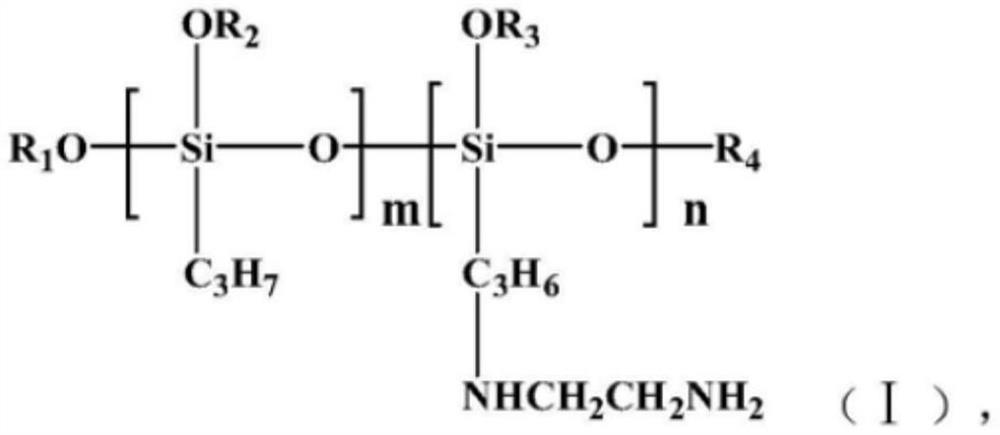

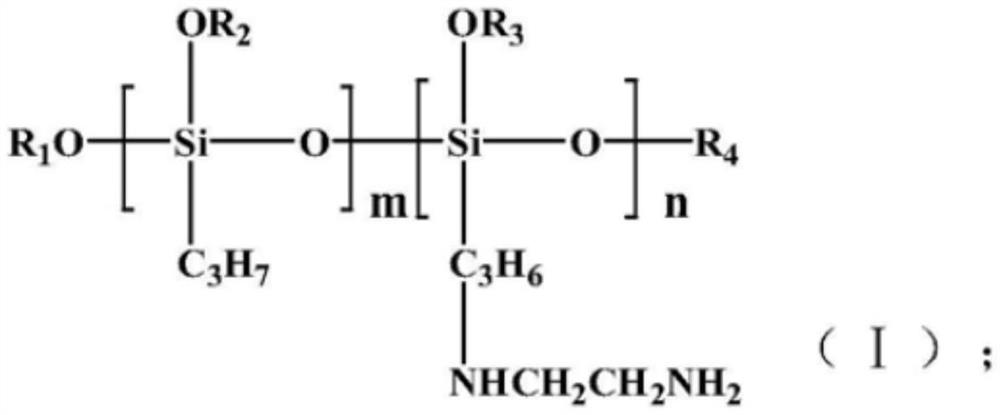

[0045] Then, 20 parts of the compound shown in formula (I-1) was mixed with 60 parts of the polyurethane prepolymer prepared by the abov...

Embodiment 2

[0048] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 40 parts of end-blocked polyurethane prepolymer, 55 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing 1 part of agent silane 171, 0.2 part of dibutyltin dilaurate, 0.7 part of fumed silica, 0.1 part of vinyltriethoxysilane, and 0.1 part of calcium oxide.

[0049] The preparation method comprises the following steps:

[0050] (1) Preparation of end-capped polyurethane prepolymer:

[0051] 50 parts of Dongda Polyether Diol 2000 and 25 parts of Dongda Polyether Diol 1000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 20 parts of BASF TDI in React at 80°C for 3 hours, stop the reaction when the measured NCO content is about 5.8%, and make 95 parts of polyurethane prepolymer;

[0052] Then, 50 parts of the compound shown in formula (I-2) was mixed with 9...

Embodiment 3

[0055] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 50 parts of end-blocked polyurethane prepolymer, 40 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing Agent silane 171 1 part, dibutyltin dilaurate 0.1 part, fumed silica 0.8 part, vinyltriethoxysilane 0.2 part, calcium oxide 0.2 part.

[0056] The preparation method comprises the following steps:

[0057] (1) Preparation of end-capped polyurethane prepolymer:

[0058] 25 parts of Dongda Polyether Diol 400 and 25 parts of Dongda Polyether Diol 1000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 45 parts of BASF MDI in React at 80°C for 2 hours, stop the reaction when the measured NCO content is about 8.17%, and make 95 parts of polyurethane prepolymer;

[0059] Then 55 parts of the compound shown in formula (I-3) were mixed with 95 parts of the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com