Production method of flame-retardant antibacterial PET (Polyethylene Terephthalate) copolyester

A production method and technology of copolyester, applied in the field of PET copolyester, can solve the problems of limiting the development of PET application fields, breeding bacteria in PET textiles, and lowering the melting point of PET polyester, so as to provide antibacterial properties, improve product color value, The effect of reducing polymerization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

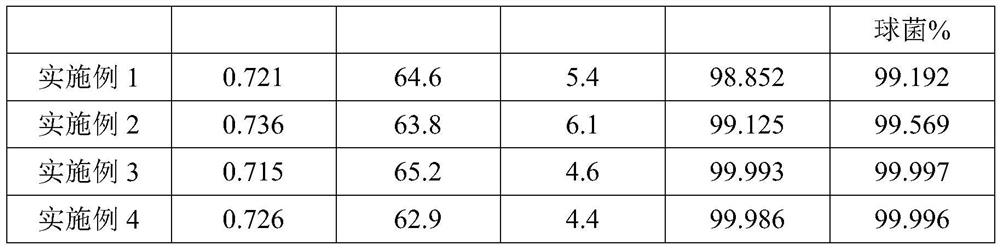

Embodiment 1

[0024] (1) Preparation of phosphorus-containing flame retardant pre-esterification solution: Take phosphorus-containing flame retardant and ethylene glycol at a mass ratio of 1:1 and add them to the esterification kettle, add an appropriate amount of catalyst and antioxidant, and The temperature is 150° C., the pressure is 0.1 MPa, and the esterification reaction is carried out for 3 hours under the condition of stirring, and the phosphorus-containing flame retardant pre-esterification liquid is obtained. (2) Preparation of antibacterial agent dispersion: take zinc oxide and ethylene glycol at a mass ratio of 1:10, stir and mix, and then disperse by ultrasonic to obtain an antibacterial agent dispersion. (3) Esterification reaction: add terephthalic acid and ethylene glycol into the polyester esterification device at a molar ratio of 1:1.4, and carry out esterification reaction at an esterification temperature of 240°C and a pressure of 0.3MPa 150min, obtain the esterification...

Embodiment 2

[0026](1) Preparation of phosphorus-containing flame retardant pre-esterification solution: take phosphorus-containing flame retardant and ethylene glycol and add them to the esterification kettle at a mass ratio of 1:1, add an appropriate amount of catalyst and antioxidant, and The temperature is 150°C, the pressure is 0.1 MPa, and the esterification reaction is carried out for 3 hours under the condition of stirring, and the phosphorus-containing flame retardant pre-esterification liquid is obtained. (2) Preparation of antibacterial agent dispersion: take zinc oxide and ethylene glycol at a mass ratio of 1:20, stir and mix, and then disperse by ultrasonic to obtain an antibacterial agent dispersion. (3) Esterification reaction: add terephthalic acid and ethylene glycol into the polyester esterification device at a molar ratio of 1:1.4, and carry out esterification reaction at an esterification temperature of 240°C and a pressure of 0.3MPa 150min, obtain the esterification pr...

Embodiment 3

[0028] (1) Preparation of phosphorus-containing flame retardant pre-esterification liquid: take phosphorus-containing flame retardant and ethylene glycol and add them to the esterification kettle at a mass ratio of 1:2, add an appropriate amount of catalyst and antioxidant, and The temperature is 170°C, the pressure is 0.1 MPa, and the esterification reaction is carried out for 2.5 hours under the condition of stirring, and the phosphorus-containing flame retardant pre-esterification liquid is obtained. (2) Preparation of antibacterial agent dispersion: take zinc oxide and ethylene glycol at a mass ratio of 1:30, stir and mix, and then disperse by ultrasonic to obtain an antibacterial agent dispersion. (3) Esterification reaction: add terephthalic acid and ethylene glycol into the polyester esterification device at a molar ratio of 1:1.2, and carry out esterification reaction at an esterification temperature of 245°C and a pressure of 0.3MPa 180min, obtain the esterification p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com