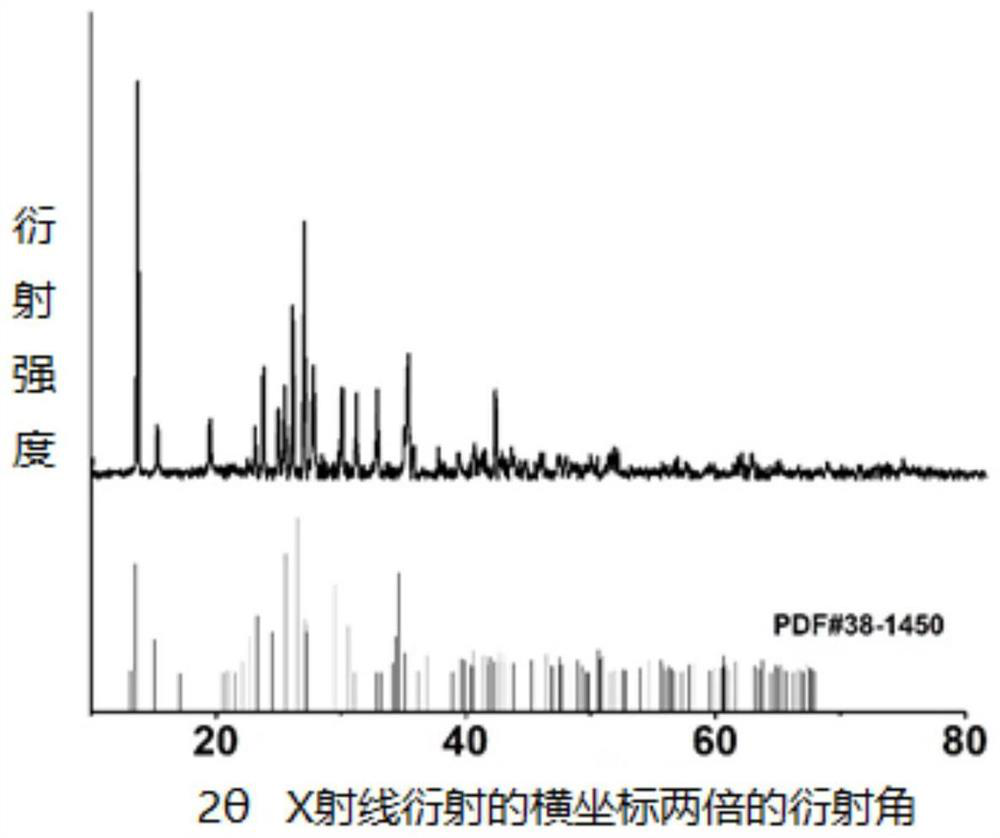

Super-hydrophobic matrix material of monoclinic-phase celsian glass ceramic and preparation method thereof

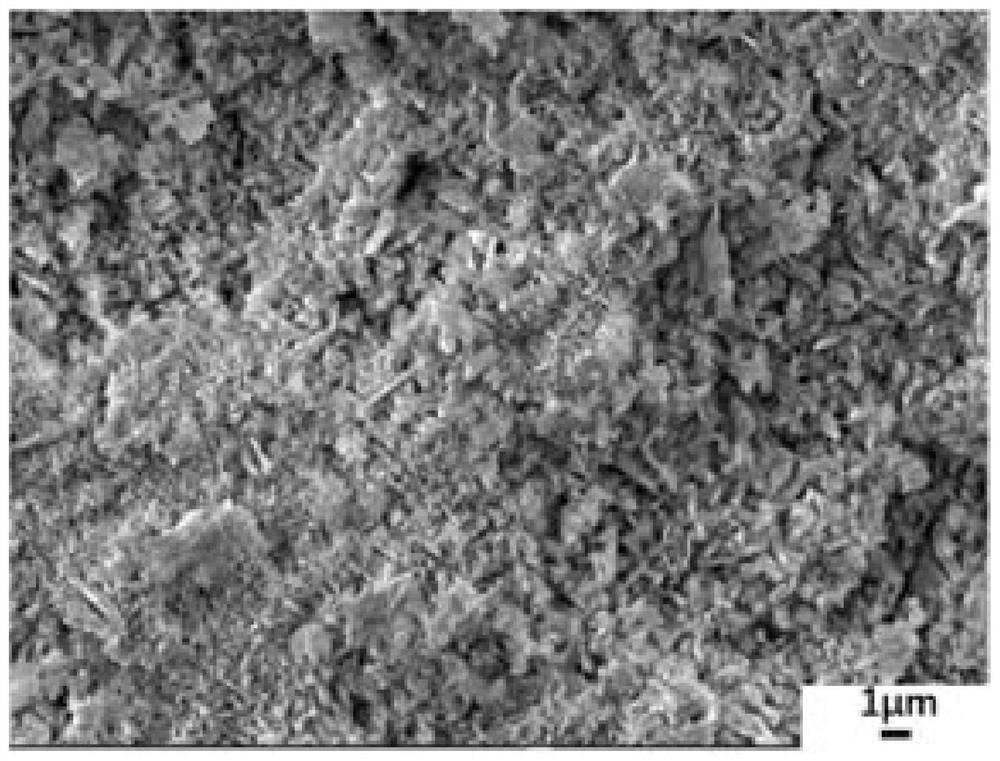

A technology of glass ceramics and matrix materials, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex process, impure crystal phase, high energy consumption, etc., and achieve firm structure, increased surface area, and good hydrophobicity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The superhydrophobic matrix material and the preparation method thereof of the monoclinic barium feldspar glass ceramics according to the embodiment of the present invention comprise the following steps:

[0037] Step 1: According to the mass percentage of raw materials, 25-55wt% of barium salt, 8-22wt% of aluminum powder, 8-26wt% of silicon powder and 0-30wt% of cosolvent are provided.

[0038] Specifically, the fluxes added to the raw materials can be boric acid and sodium chloride, which can promote the transformation of the hexagonal phase into a monoclinic phase and reduce the melting temperature, and can also effectively reduce energy consumption.

[0039] In step 2, the above raw materials are mixed and melted to obtain a clarified molten glass, and / or a glass frit obtained by quenching a part of the molten glass.

[0040] Wherein, deionized water can be used for quenching. The temperature of the high-temperature melting is 1000-1700° C., and the holding time is...

Embodiment 1

[0053] 1) Provide barium carbonate 55wt%, aluminum oxide 12wt%, silicon dioxide 25wt%, obtain glass powder raw material

[0054] 2) Add 6wt% boric acid and 2wt% sodium chloride to the above-mentioned glass powder raw material, mix thoroughly with a mixer, put it into a platinum crucible, and put it into a lifting type silicon-molybdenum rod electric furnace that has been heated to 1550°C in advance and keep it warm for one hour to melt. Pour the obtained molten glass into deionized water at room temperature and quench to obtain barium feldspar to form a glass frit. The glass frit is broken into small pieces and put into a polyurethane ball mill jar. Water is used as deionized water as the dispersion medium, zirconia balls are used as the ball milling medium, and the ball: glass: water mass ratio is about 3:1:1, and the ball is milled on a ball mill. Pour the ball-milled slurry into a clean enamel basin, and dry it in an electric blast drying oven at 75°C. The dried block is...

Embodiment 2

[0064] 1) Provide barium carbonate 54wt%, aluminum oxide 12wt%, silicon dioxide 25wt%, obtain glass powder raw material

[0065] 2) Add 8wt% boric acid and 1wt% sodium chloride to the above-mentioned glass powder raw material, mix thoroughly with a mixer, put it into a platinum crucible, and put it into a lifting type silicon-molybdenum rod electric furnace that has been heated to 1550°C in advance and keep it warm for one hour to melt. Pour the obtained molten glass into deionized water at room temperature and quench to obtain barium feldspar to form a glass frit. The glass frit is broken into small pieces and put into a polyurethane ball mill jar. Water is used as deionized water as the dispersion medium, zirconia balls are used as the ball milling medium, and the ball: glass: water mass ratio is about 3:1:1, and the ball is milled on a ball mill. Pour the ball-milled slurry into a clean enamel basin, and dry it in an electric blast drying oven at 75°C. The dried block is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com