Leaching/wet detoxification method for different chromium pollution media

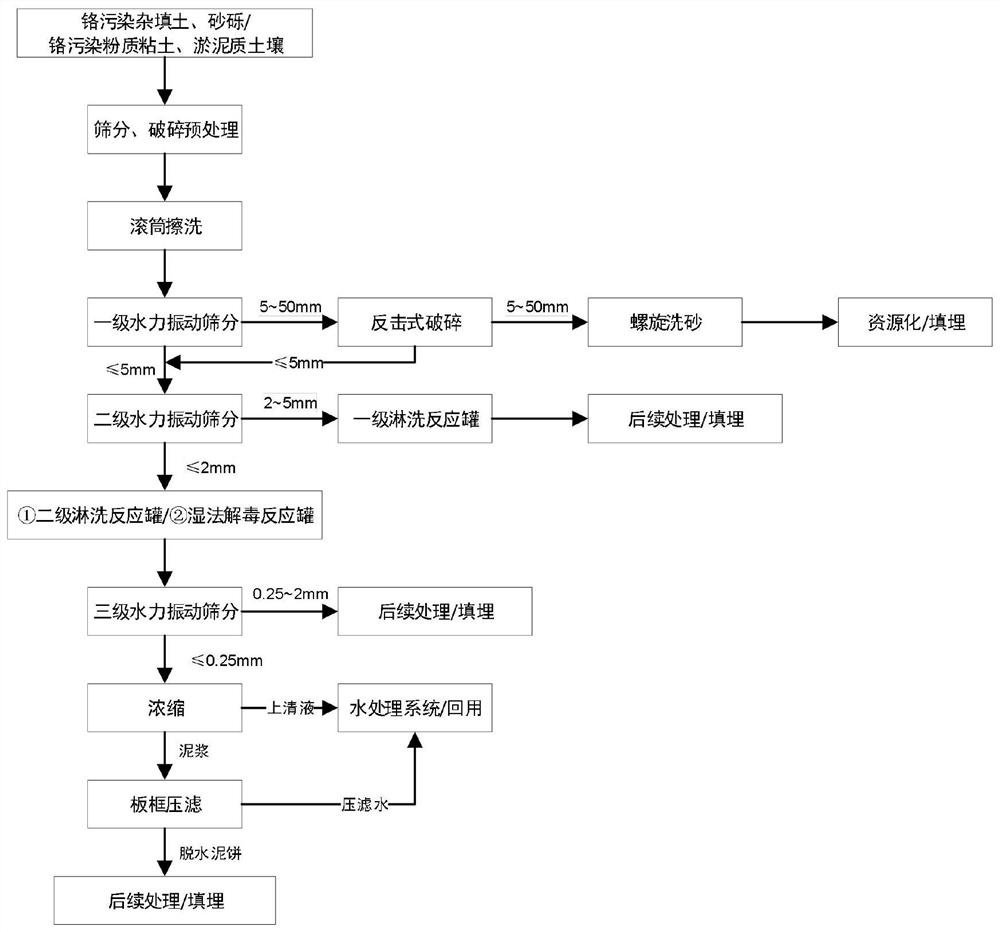

A wet detoxification and chromium pollution technology, applied in the field of pollutant treatment, can solve the problems of low ball milling efficiency, particle size reduction, complicated operation, etc., and achieve the effects of reducing equipment investment, saving land, and ensuring the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Chromium-contaminated miscellaneous fill at the former site of a chromium salt factory in Hunan.

[0057] Step 1: Pre-treat the chromium-contaminated miscellaneous fill, remove large particles > 50mm, and then transport it to a drum scrubber to make a chromium-containing slurry. The processing scale is 100t / h, and the solid-liquid mass ratio of the slurry is controlled. It is 1:3.

[0058] Step 2: The slurry is sieved by a primary hydraulic vibrating sieve, and the sieve (5~50mm) is crushed by an impact crusher to crush a small amount of chromium slag mixed in the soil to ≤5mm, and the sand on the sieve (5~50mm) After being cleaned by the spiral sand washing machine, the chromium slag and fine particle materials under the screen and the undersize (≤5mm) of the primary hydraulic vibrating screen are screened by the secondary hydraulic vibrating screen.

[0059] Step 3: Sieve with the secondary hydraulic vibrating sieve, and the sieved material (2~5mm) enters the primary...

Embodiment 2

[0068] Chromium-contaminated muddy soil at the former site of a chromium salt factory in Hunan.

[0069] Step 1: pre-treat the chrome-contaminated muddy soil, remove large particles > 50 mm, and then transport it to a drum scrubber to make a chromium-containing slurry. The processing scale is 35t / h, and the solid-liquid mass ratio of the slurry is controlled to be 1:2.

[0070] Step 2: The slurry is sieved by a primary hydraulic vibrating sieve, and the sieve (5~50mm) is crushed by an impact crusher to crush a small amount of chromium slag mixed in the soil to ≤5mm, and the sand on the sieve (5~50mm) After being cleaned by the spiral sand washing machine, the chromium slag and fine particle materials under the screen and the undersize (≤5mm) of the primary hydraulic vibrating screen are screened by the secondary hydraulic vibrating screen.

[0071] Step 3: Sieve with the secondary hydraulic vibrating sieve, and the sieved material (2~5mm) enters the primary leaching reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com