Silicon carbide ceramic filtering membrane group for industrial cutting fluid regeneration

A silicon carbide ceramic and cutting fluid technology, applied in the field of silicon carbide ceramic filtration membrane group, can solve the problems of unreasonable setting of ceramic membrane filtration aperture, poor sterilization and suspended solid removal effect, affecting the effect of regenerated cutting fluid, etc. The effect of equipment purchase cost and maintenance cost, reduction of solid matter and waste oil, and improvement of regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

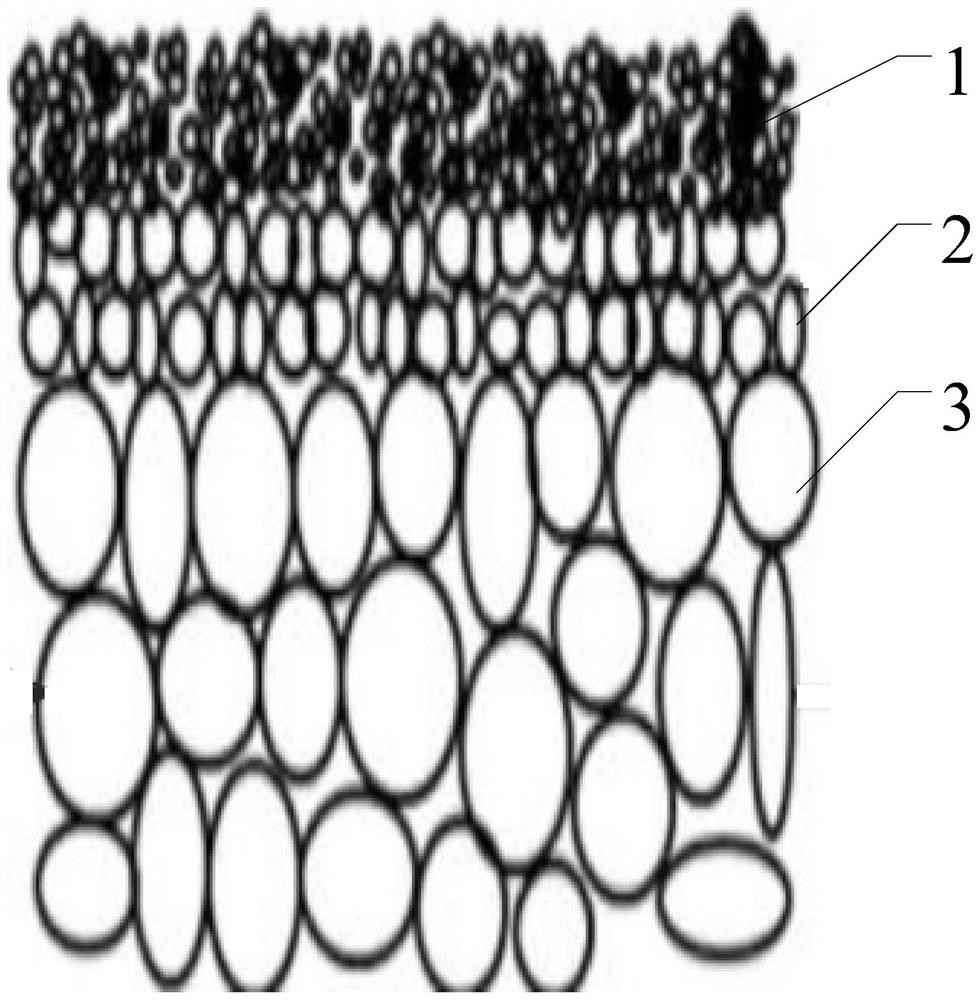

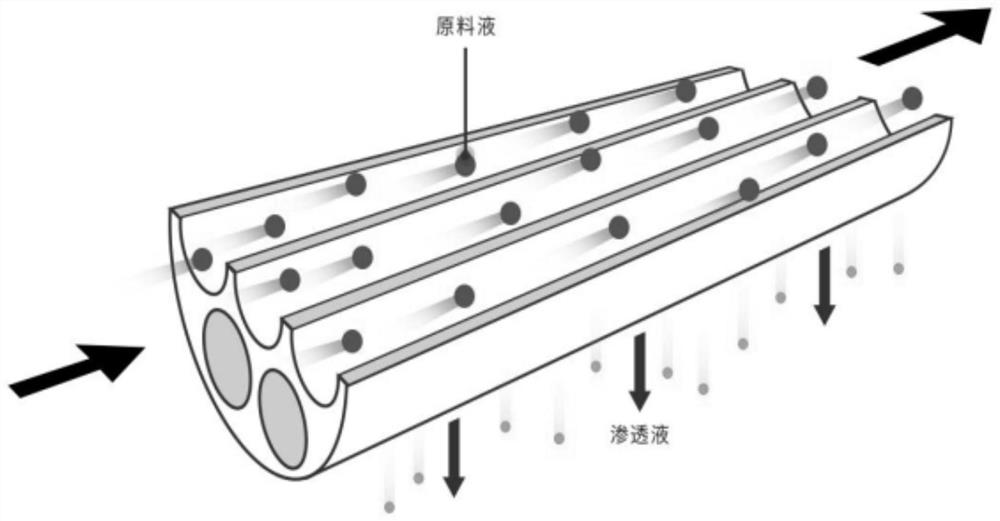

[0031] figure 1 It is an interlayer layout diagram of a silicon carbide ceramic filter membrane group used for industrial cutting fluid regeneration according to an embodiment of the present invention; figure 2 It is an embodiment of the present invention a kind of overflow channel arrangement diagram of the silicon carbide ceramic filter membrane group that is used for the regeneration of industrial cutting fluid, such as figure 1 and figure 2 As shown, the structure of the present invention includes a filter membrane layer 1, a transition layer 2 and a support layer 3 arranged sequentially from inside to outside along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com