Preparation of amorphous polyaryletherketone (sulfone)-hydroxyapatite 3D printing material

A technology of hydroxyapatite and polyaryletherketone, which is applied in the direction of additive processing, etc., can solve problems such as single method, poor solubility of PEEK, and unsatisfactory uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

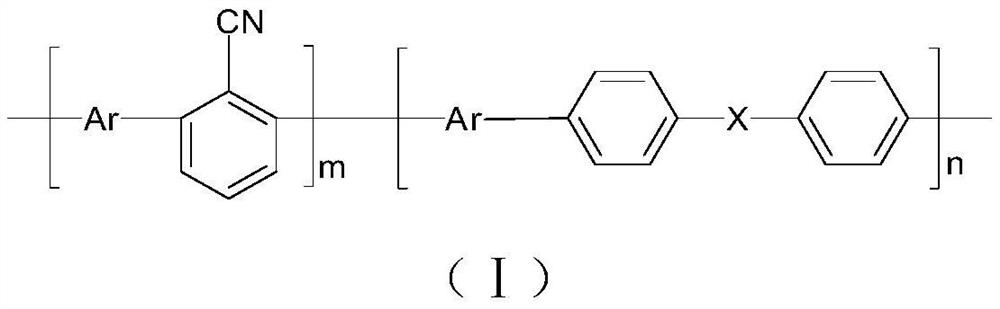

[0008] The invention discloses a method for preparing an amorphous polyaryletherketone (sulfone)-hydroxyapatite 3D printing material, the method comprising:

[0009] Step 1: taking amorphous polyarylether ketone and / or amorphous polyarylether sulfone powder and hydroxyapatite co-dissolved in a polar aprotic solvent to form a viscous liquid, then stirring, and ultrasonic treatment at the same time;

[0010] Step 2: Precipitate the viscous liquid obtained in Step 1 in a solution with a volume ratio of ethanol to water of 5: (1-10) (preferably 5: (4-6)), and filter and pulverize the precipitate , and repeatedly boiled and washed with deionized water 5 to 10 times (preferably 6 to 8 times), dried in a vacuum oven at 100 to 160°C (preferably 120 to 150°C) for 10 to 24h (preferably 18 to 24h), That is, the amorphous polyaryletherketone (sulfone)-hydroxyapatite 3D printing composite material after preliminary blending is obtained;

[0011] Step 3: Melt and extrude the amorphous poly...

Embodiment 1

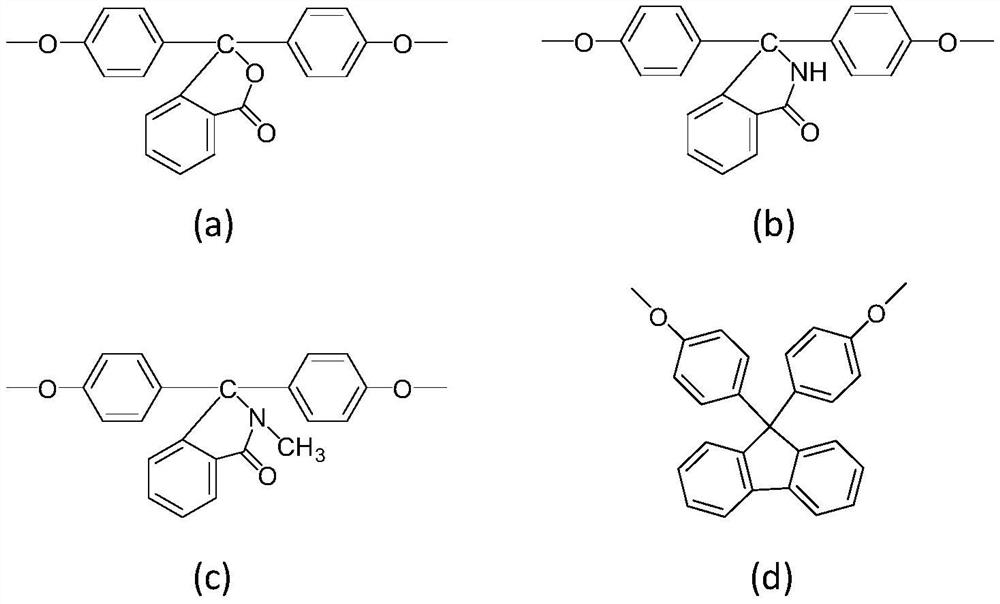

[0024] Add phenolphthalein (the structure is shown in (a) above, the same below) (400mmol), 2,6-dichlorobenzonitrile (280mmol), 4,4'-difluorobenzophenone (120mmol), 4 - Fluorobenzophenone (12mmol), potassium carbonate (480mmol), sulfolane (600g), toluene (120ml), under the protection of nitrogen, heat the above mixture to 150°C while stirring to azeotropically remove water, keep the temperature for 3h, remove Toluene and water, continue to heat to 210 ° C for 3.5 hours, stop heating, transfer the reactant to a solution with a volume ratio of ethanol and water of 1:1 for precipitation, the precipitate is filtered, crushed, and repeatedly boiled and washed with deionized water Inorganic salts and residual solvents were removed six times, and dried in a vacuum oven at 150°C for 24 hours to obtain a polymer powder with the structure (II), which was verified by H NMR and IR spectroscopy.

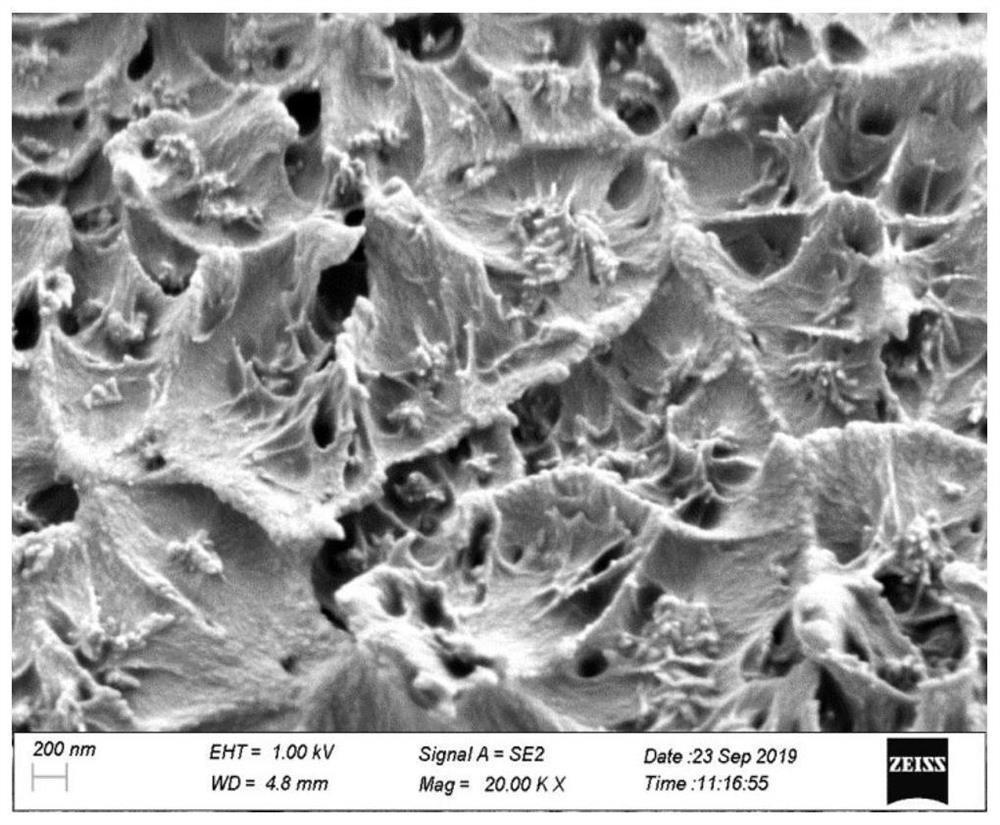

[0025] Take 100g of amorphous polyaryletherketone (structure as shown in formula II) powder, ...

Embodiment 2

[0030] Take 100 g of amorphous polyarylether ketone (structure as shown in formula II) powder prepared in Example 1 and 5 g of hydroxyapatite, dissolve them in 500 ml of N,N-dimethylacetamide, stir, and make a viscous Thick liquid, then high-speed stirring at 8000rpm, and ultrasonic vibration at 60KHz frequency at the same time, the processing time is 60min. Then the obtained viscous liquid is precipitated in a solution with a volume ratio of ethanol and water of 1:1, the precipitate is filtered, crushed, and repeatedly boiled and washed with deionized water for 6 times to remove the residual solvent, and then heated in a vacuum oven at 150°C After drying for 24 hours, the amorphous polyaryletherketone-hydroxyapatite 3D printing composite material after preliminary blending was obtained; then, the composite material powder obtained by the solution method was melt-extruded in a twin-screw at 350 °C, and the screw speed was 100rpm, and under the action of the traction device, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com