Device for forging liquid metal through ultrahigh-pressure nitrogen

A technology of liquid metal and high-pressure nitrogen, which is applied in the field of production equipment of mechanical parts, can solve the problems that mechanical parts cannot meet the requirements of mechanical operation, etc., and achieve the effects of reducing grain size, improving tensile strength, and increasing grain density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

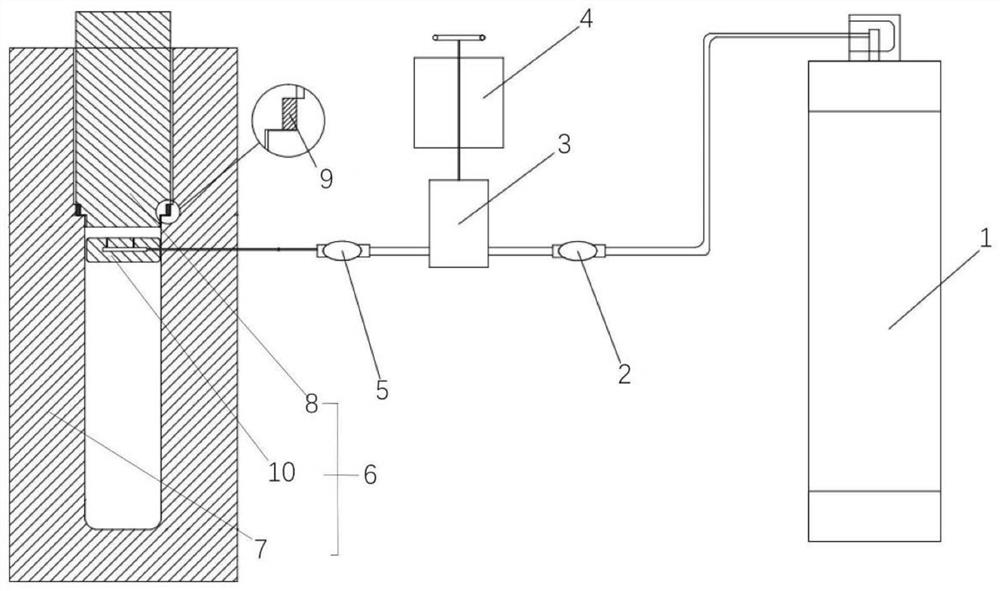

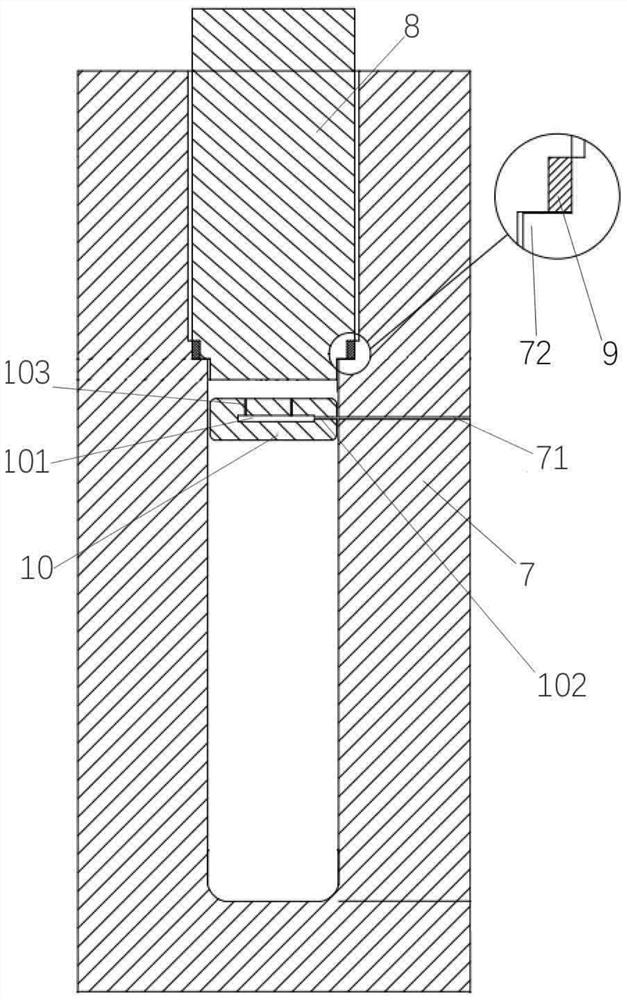

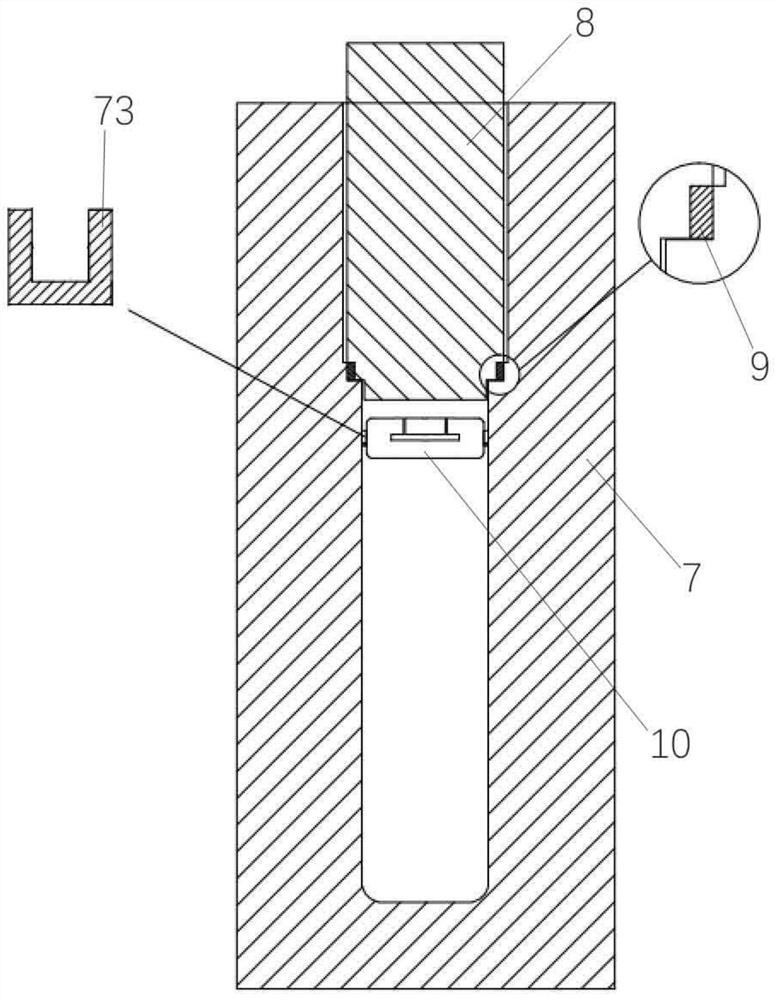

[0020] Such as Figure 1-5 As shown, a device for forging liquid metal with high-pressure nitrogen includes a liquid nitrogen tank 1, a check valve one 2, a plunger pump 3, an oil cylinder 4, a check valve two 5 and a liquid metal pressurizing device 6, and the liquid nitrogen Tank 1, one-way valve one 2, plunger pump 3, one-way valve two 5 and liquid metal pressurizing device 6 are connected in sequence, and the plunger pump 3 is driven and pressurized by the oil cylinder 4; the liquid metal pressurizing device 6 includes a cylinder 7, a cock 8, a sealing assembly 9, and a liquid nitrogen gasification generating device 10. The cock 8 is rotatably matched with the cylinder 7, and the cock 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com