Sulfur hexafluoride gas separation and recovery device

A technology for the separation and recovery of sulfur hexafluoride gas, which is applied in gas/liquid distribution and storage, gas treatment/storage effects, sulfur compounds, etc. It can solve the problems of poor purification accuracy and low recovery efficiency, and achieve fast recovery speed, The effect of improving recovery purity and avoiding pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

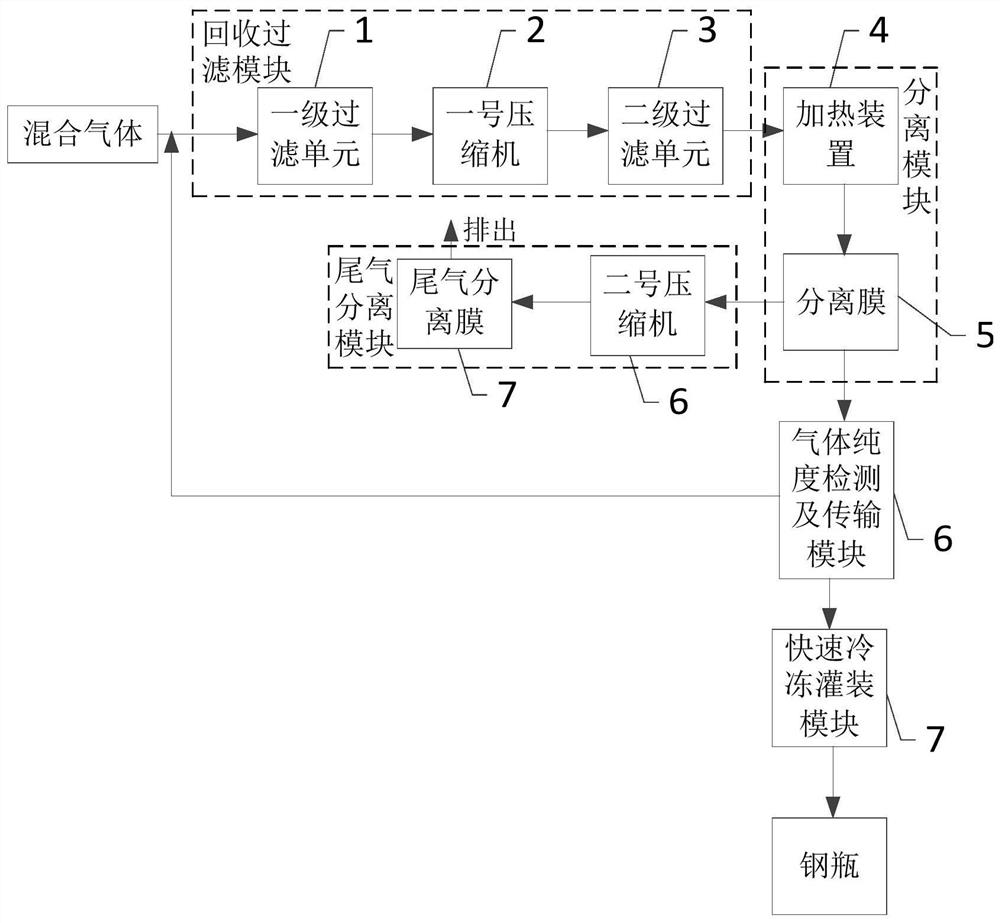

[0034] Embodiment 1: Combining Figure 1 to Figure 2 Illustrating this embodiment, the sulfur hexafluoride gas separation and recovery device described in this embodiment includes a recovery filter module, a separation module, a tail gas separation module, a quick freezing filling device 7 and a gas purity detection and transmission module 6,

[0035] The recovery filter module is used to extract the mixed gas for filtering, and the filtered gas is pressurized and transferred to the separation module;

[0036] The separation module is used to separate the filtered gas into sulfur hexafluoride gas and gas other than sulfur hexafluoride gas. The gas other than sulfur hexafluoride gas enters the tail gas separation module, and the sulfur hexafluoride gas enters the gas purity detection and transmission module 6;

[0037] The tail gas separation module is used to separate gases other than sulfur hexafluoride gas, and the separated gases are discharged separately;

[0038] The ga...

specific Embodiment approach 2

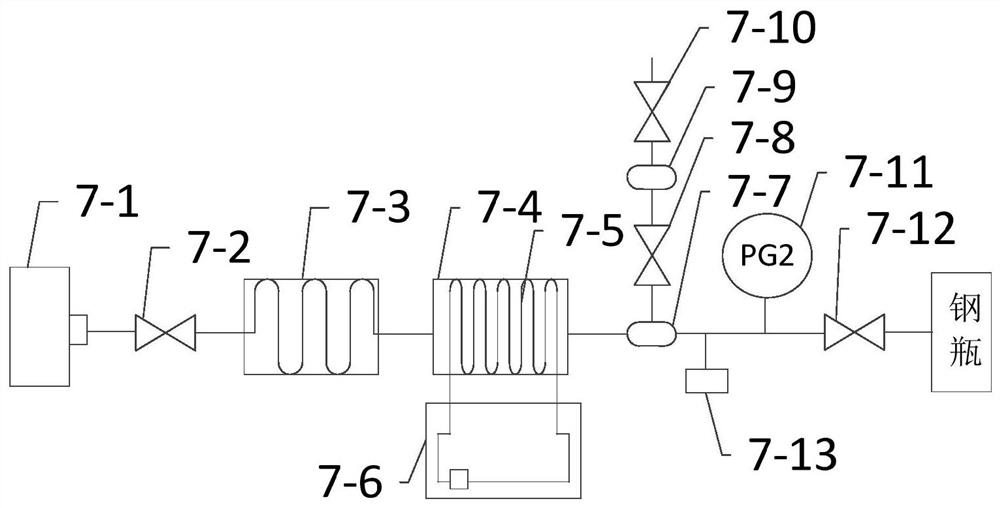

[0043] Embodiment 2: This embodiment further defines the sulfur hexafluoride gas separation and recovery device described in Embodiment 1. In this embodiment, the freezing filling device 7 further includes an exhaust valve 7-10,

[0044] Through the control of the exhaust valve 7-10, the air impurities that are not easily liquefied in the upper tank body 7-9 are discharged.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment further defines the sulfur hexafluoride gas separation and recovery device described in Embodiment 1. In this embodiment, the freezing filling device 7 further includes pressure gauges 7-11,

[0046] The pressure gauge 7-11 is set on the pipe between the manual valve 7-12 and the pressure transmitter 7-13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com