Modified metal organic framework (MOF) compound material, preparation method, proton exchange membrane and application thereof

A metal organic framework, proton exchange membrane technology, applied in the field of proton exchange membrane, preparation method, modified MOF material, can solve the problem of low membrane selectivity, affecting the service life of vanadium redox flow battery, proton exchange membrane proton conductivity and It is difficult to improve the performance of vanadium ion resistance at the same time, so as to achieve the effect of high proton conductivity and low vanadium ion permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to one aspect of the present invention, a kind of preparation method of modified MOF material is provided, comprising the following steps:

[0047] Provide a mixed solution containing MOF, monomer and initiator;

[0048] removing the air in the pores of the MOF in the mixed solution, and

[0049] In-situ free radical polymerization of the monomers in the mixed solution;

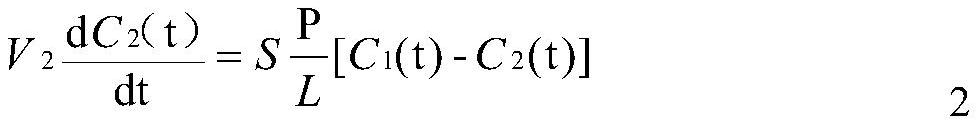

[0050] Wherein, the monomer contains a sulfonate group, and the window size of the MOF is smaller than (Such as figure 1 middle is the window size).

[0051] In the present invention, monomers, initiators and MOFs are prepared into a mixed solution. In the mixed solution, monomers and initiators exist in MOF pores. After removing the air in MOF pores, the monomers present in MOF pores Under the action of the initiator, the in-situ radical polymerization reaction occurs, and the monomers are polymerized into polymers in the pores of the MOF. The polymer shuttles and connects in the con...

Embodiment 1

[0082] Dissolve 1.0 g of sodium p-styrenesulfonate in N,N-dimethylformamide / water (12mL, 10:2v:v) solution, and then add azobisisobutyronitrile (mass of sodium p-styrenesulfonate 3%) was added to the aforementioned dispersion. After that, 0.7g of UiO-66 was added to the sodium p-styrenesulfonate-azobisisobutyronitrile solution, and N 2 , and then vacuumed for 10 minutes, repeated three times to remove the oxygen in the pores of the MOF. The aforementioned dispersion was stirred in an 80° C. oil bath under a nitrogen atmosphere for 5 days. After the product is collected, soak it in N,N-dimethylformamide for a period of time to remove unreacted sodium p-styrene sulfonate and unfixed polyvinylbenzene sulfonate, and collect the product after drying. The resulting modified MOF material has a size of about 50 nm.

[0083] Disperse the above-mentioned modified MOF evenly in deionized water to make a dispersion liquid, dissolve sulfonated polyether ether ketone in N,N-dimethylaceta...

Embodiment 2

[0085] Dissolve 1.0 g of sodium p-styrenesulfonate in N,N-dimethylformamide / water (12mL, 10:2v:v) solution, and then add azobisisobutyronitrile (mass of sodium p-styrenesulfonate 3%) was added to the aforementioned dispersion. Then take 0.7g of UiO-66-NH 2 Add it into the sodium p-styrenesulfonate-azobisisobutyrocyanide solution. After stirring evenly, nitrogen gas is introduced, and then vacuumed for 10 minutes. Repeat three times to remove the oxygen in the pores of the MOF. The aforementioned dispersion was stirred in an 80° C. oil bath under a nitrogen atmosphere for 5 days. After collecting the product, soak it in N,N-dimethylformamide for a period of time to remove unreacted sodium p-styrene sulfonate and unfixed polyvinylbenzene sulfonate, and dry it to collect the product.

[0086] The film-forming process of the proton exchange membrane is the same as in Example 1, except that the modified MOF used is replaced by the modified MOF prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com