Flexible coiled material with grids and glass fibers

A glass fiber and flexible technology, applied in the field of grid and glass fiber flexible coils, can solve the problems of the coil's anti-aging performance, stability and service life, inconvenient handling, and laborious laying, etc., to increase the anti-aging performance. Performance, service life increase, effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

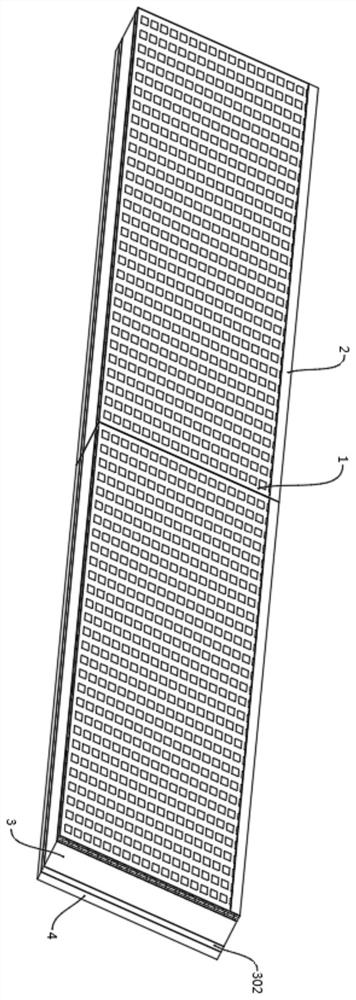

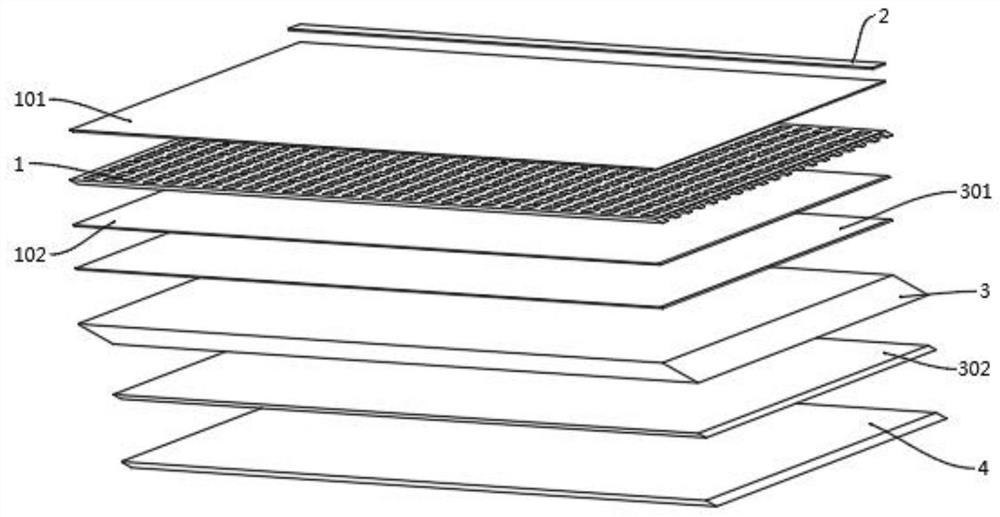

[0047] as attached figure 1 to attach Figure 5 Shown:

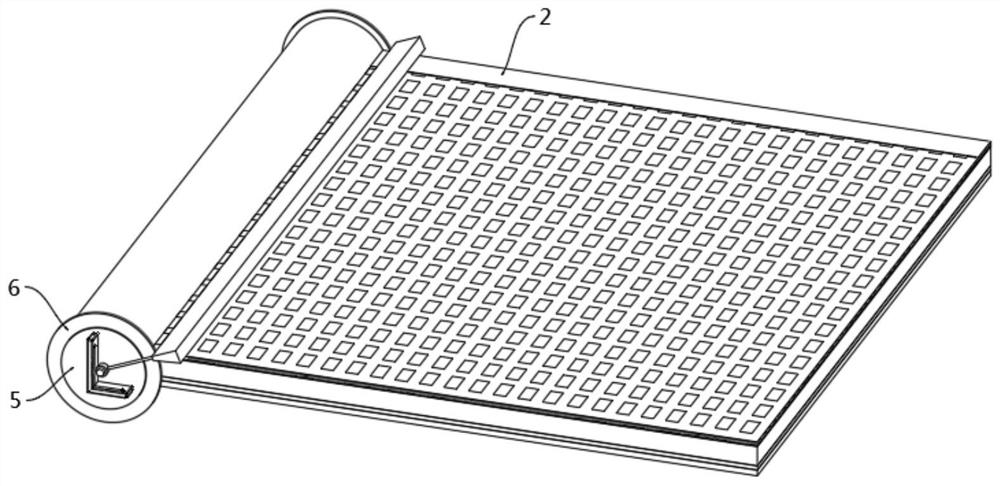

[0048] The invention provides a flexible roll material with grid and glass fiber, which includes a grid layer 1; an adhesive strip 2 is provided on the top side of the grid layer 1, and a main body layer 3 is provided at the bottom of the grid layer 1; the main body layer 3 The bottom is provided with a base layer 4; the bottom surface of the base layer 4 is covered with an anti-adhesive film; the grid layer 1, the adhesive strip 2, the main layer 3 and the base layer 4 are pressed together to form a coil and then wound around the periphery of the rotating component 5, and the coil The two ends of the coil are beveled structure, which enables the two sets of coils to become one after pressing and heat-melting and maintain a high degree of uniformity at the bonding point.

[0049] as attached figure 2 As shown, the main body layer 3 includes: an upper adhesive layer 301 and a lower adhesive layer 302, the upper adhesi...

Embodiment 2

[0056] Embodiment 2, on the basis of Embodiment 1, the pressure plate 502 can be connected to the connecting ring 5021 through a threaded rod, and other structures remain unchanged. When the coiled material does not have a roller shaft, use the threaded tapered end of the insertion shaft 501 to insert into the center of the coiled material. Subsequently, the connecting ring 5021, the limit plate 506, the rotating plate 6 and the fixed disk 505 are sleeved on the periphery of the inserting shaft 501 in sequence, and then the screw cap 504 is connected to the end of the inserting shaft 501 through threaded engagement, and the connecting ring is connected by a threaded rod. 5021 is connected with the pressing plate 502, and the rotating assembly 5 can be used to perform the paving operation in the waterproof operation.

[0057] The specific usage and function of this embodiment:

[0058] In the present invention, the grid layer 1 is used to make the coiled material more viscous, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com